0102030405

Wall Magnetic Formwork System For Concrete

The wall magnetic concrete formwork system is always seen on the production line of the precast plant. It is fixed and positioned by strong neodymium magnets to improve construction efficiency and safety. It consists of a steel shell and a varying number of strong neodymium iron boron magnet arrays. These magnets are built into steel slots to provide a safe and efficient way to assemble and fix the frame. The magnets generate a strong adhesion force to fix the entire system in place, allowing the frame to be accurately closed and positioned.

Advantages

1. Improve construction efficiency: The system can speed up the installation and removal of formwork to improve overall construction efficiency.

2. Ensure construction quality: The strong adhesion of NdFeB magnets can ensure that the steel bars are in the correct position, and the error coefficient is smaller than that of traditional welding or bolting.

3. Improve safety: The use of the Wall magnetic formwork system can avoid sparks and flames during welding, eliminating the risk of fire accidents.

4.Flexibility: When used to produce precast concrete components of different geometries and sizes, the flexibility of the system can be fully reflected. This flexibility comes from the system's multiple sizes, multiple adhesions, and multiple combinations between different models.

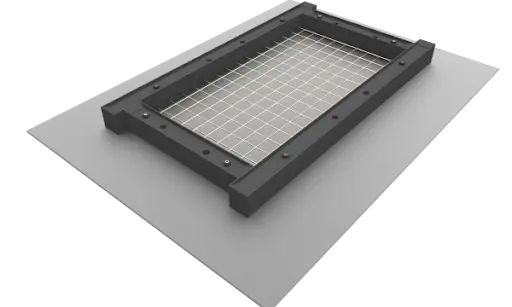

Wall magnetic formwork system for concrete application 3D image

Production process

The production process of the wall magnetic formwork system is divided into multiple steps, mainly the assembly of the magnetic array and the processing and forming of the shell. In the early stage, the NdFeB magnets in the magnetic array need to be covered with a protective ring to prevent the exposed surface of the magnet from being exposed to the air and corroded, and also to avoid direct contact with sharp objects and wear. This process is to extend the service life of the NdFeB magnets.

Common Specifications

The wall magnetic formwork system has a variety of sizes, and you can choose the appropriate model according to your needs. Common lengths include 1m, 1.5m, 2m, 3m, 3.5m, and 4m, with a width of 60mm and a height of 60MM, 65MM, 70MM, 85MM, 100MM, etc. Different numbers of magnets are built in according to different lengths to meet different load requirements.

Application Scenarios

1. production of precast concrete walls, floor slabs, beams and other structural elements.

2. construction of bridges and infrastructures to improve safety and quality of construction.

3. Tilt-up construction projects where magnets provide the necessary stability and support.

Magnetic formwork technology for concrete walls is used in prefabrication plants

The benefits of using the Wall Magnetic Concrete Formwork System are obvious. It can speed up the construction process of the building project, and the formwork can be fixed and removed faster and more safely. These advantages also reduce project and time costs, which is more economical in the long run.