0102030405

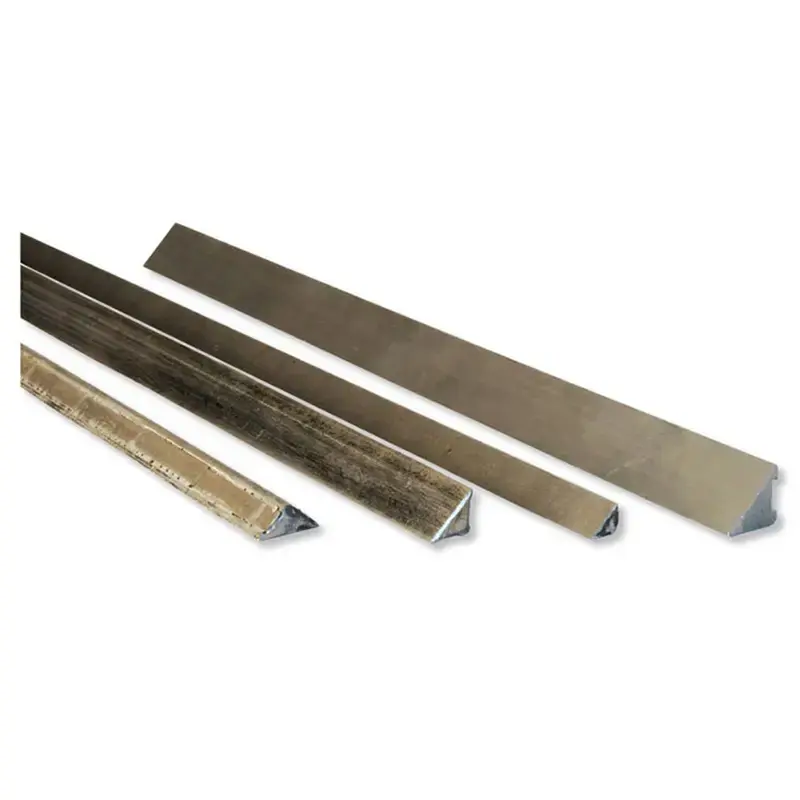

Trapezoidal Magnetic Chamfering Strip

Trapezoidal Magnetic Chamfering Strip is applied where vertical form walls meet form bases to quickly and cleanly form drip moldings, or dummy joints. Our magnetic strips are made of high quality steel (some encased in rubber) with built-in magnets.

Trapezoidal Magnetic Chamfering Strip

It uses the magnetic fixing principle to hold the chamfer strip firmly in place on the mold, thus creating the desired drip channel during the concrete pouring process. This chamfer strip can be placed at the edge position of the mold to create a variety of precast drip channels or dummy joints.

Trapezoidal Magnetic Chamfering Strip Properties

|

Place of Origin |

China |

|

Brand Name |

QCM |

|

Model Number |

QCM-DT002T |

|

Material |

magnets+steel strip |

|

Dimensions |

trapezoid 12*16*10 |

|

Holding force |

with magnet |

|

N.W. |

1.1KG/M |

|

Surface treatment |

rust prevention |

|

Service life |

1-3 years |

|

Minimum order quantity |

100 meters |

Cross section of a Trapezoidal Magnetic Chamfering Strip

Features of Trapezoidal Magnetic Chamfering Strip include:

1. high strength, not easy to slip and deform.

2. embedded with strong magnets, such as NdFeB, which can be accurately positioned at any position of the bottom or side mold.

3. reusable, cost-saving and extremely convenient for actual production use.

4. provides a quick and clean way to form drip grooves, dummy joints, notches, and reveals in concrete wall panels.

5. prevents concrete from spilling through gaps between precast concrete pouring tables and side forms.

6. it avoids the need for screwing or welding on the table slab or formwork.

7. improves production time and labor costs for precast concrete elements.

Trapezoidal Magnetic Chamfering Strip 12×16×10

Its advantages are reflected in:

1. Improved production efficiency of precast concrete parts.

2. Improving the quality and aesthetics of the product.

3. long service life of at least 3 years as the chamfering strips are reusable, ensuring a good return on investment and saving money.

4. Powerful magnets embedded in the surface of the chamfering strips provide maximum adsorption, for example, single sided magnetic steel chamfering strips provide more than 100 kilograms of strength per meter and will not be pulled out under normal use.

5. Rubber magnetic chamfering strips are magnetized on both sides, steel magnetic chamfering strips can be supplied magnetized on one side (50% magnetic) or both sides (100% magnetic).

6. easy to handle, quick to position, remove and clean, quickly and accurately locate the exact beveled chamfer on your construction steel molding table, shortening production schedules.

7. No open recesses to fill with concrete. Safely, no screws, bolts or welds are required, thus maintaining surface finish and increasing service life.

In summary, the Trapezoidal Magnetic Chamfering Strip is a useful tool for improving efficiency and product quality in precast concrete production, and its magnetic fastening, customizability, durability, and ease of handling make it an advantageous choice.