0102030405

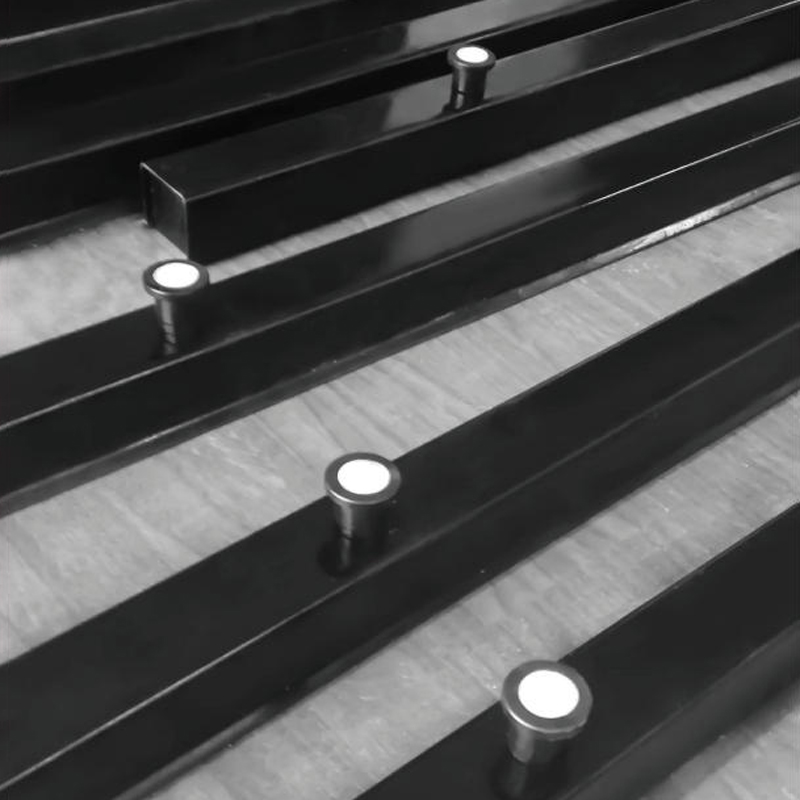

Magnetic Side Rail Magnet System for Locating Formwork

Magnetic Side Rail Systems are ideally suited for use on flat casting tables, which produce walls and slabs efficiently. As the magnets provide a strong Pull force, bolt drilling or welding templates on site is avoided. This is an efficient and flexible way to position the rail for a wide range of products.

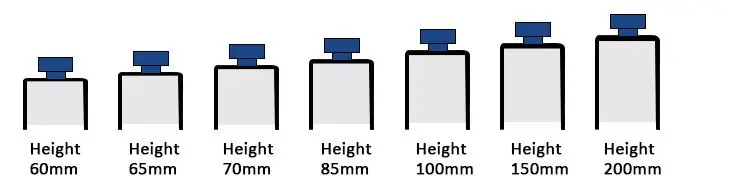

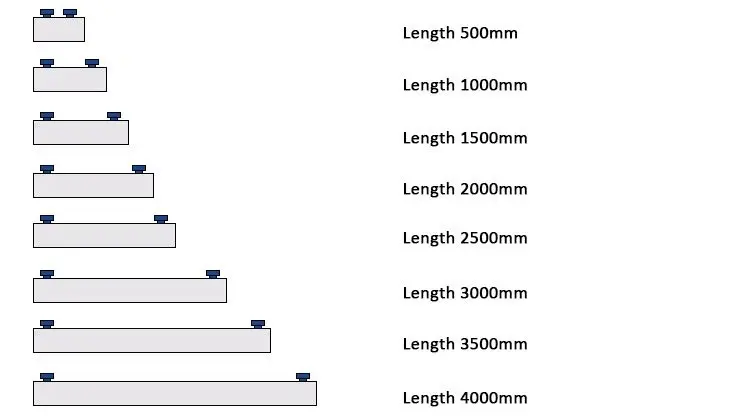

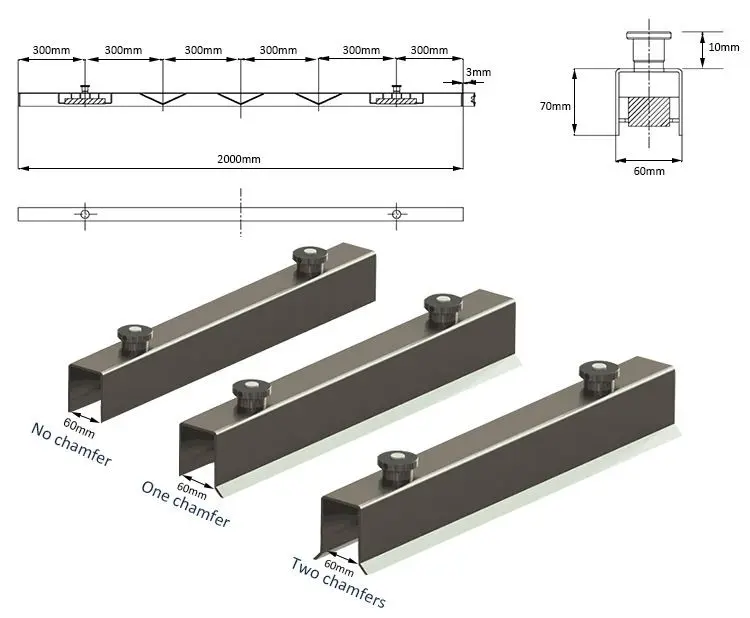

Designed to be robotically handled or manually positioned and locked, Magnetic Side Rail Systems allow easy activation and release of magnet force with the press of a switch button. Available in panel heights of 60-200mm, panel lengths of 500-4000mm, without tilted edges and with 1 chamfered edge or 2 chamfered edges. No need to disengage the built-in powerful neodymium magnets to move the side rails, easy to operate safe and fast to use.

Advantages of the magnetic side rail system:

1.integrated monolithic design, the system will not shift and ensure the consistency of the concrete components.

2.Push-button design makes the operation more convenient.

3.Built-in powerful neodymium magnet with high holding power.

4.The magnet is in the steel groove, avoiding the intrusion of concrete residue and dirt.

5.The size and magnet adhesion can be customized according to customer's requirement.

6.3 kinds of inclined edge design, easy to form precise chamfer for concrete products.

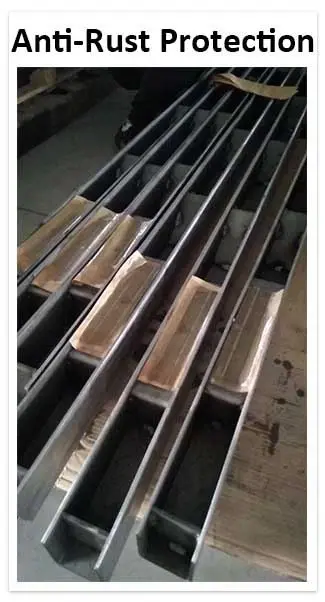

Anti-Rust Protection

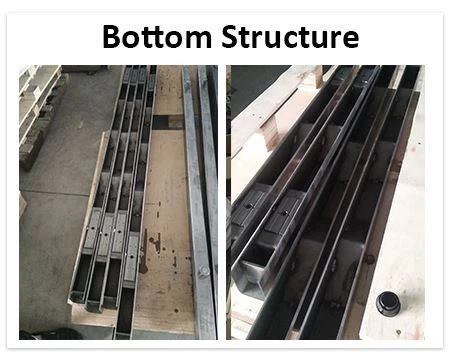

Bottom Structure

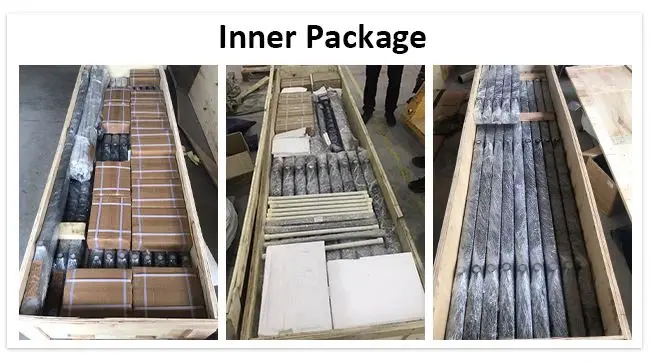

Inner Package

Wooden Case Package