0102030405

Precast Formwork with Shuttering System Magnet

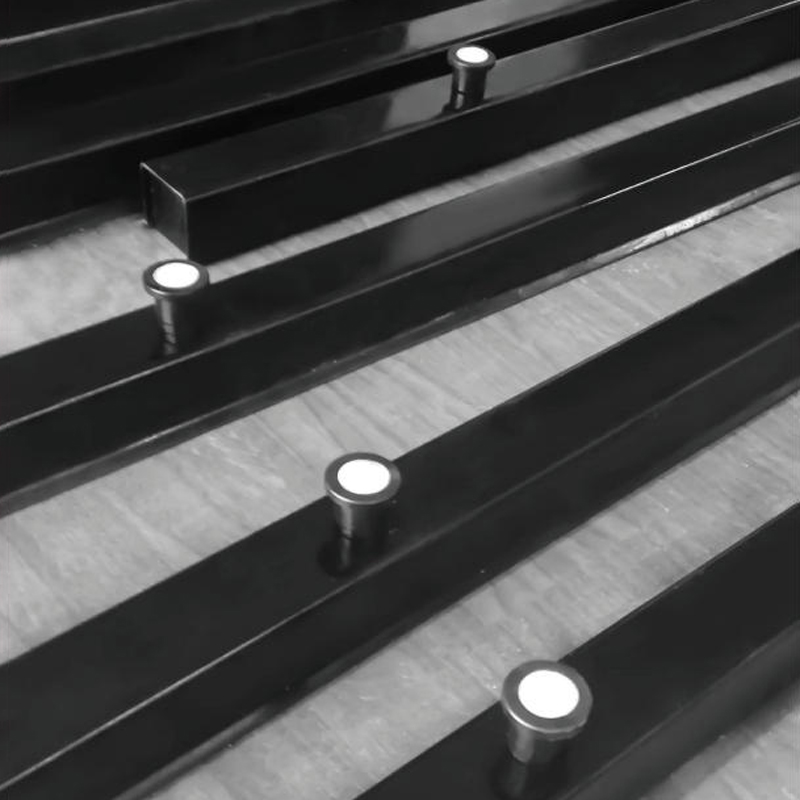

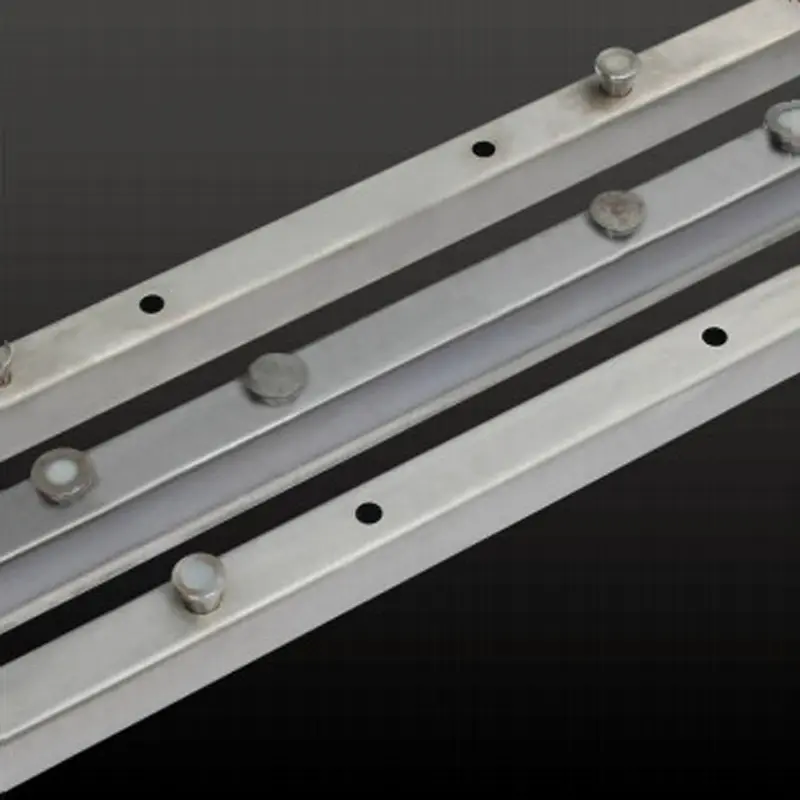

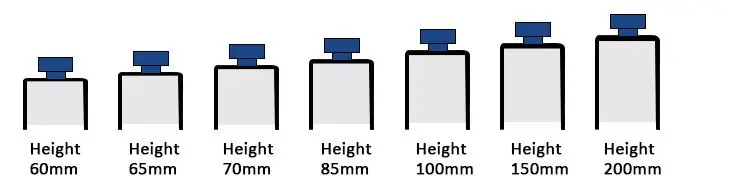

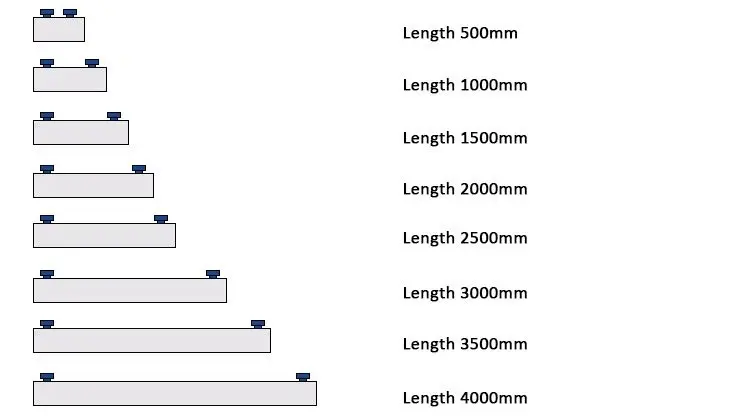

The precast concrete Shuttering system magnet is made up of formwork steel bars and embedded magnetic suction cups system, the width of the steel formwork is 60mm, the height is 60MM, 65MM, 70MM, 85MM, 100MM, etc., the length is 1m, 1.5m, 2m, 3m, 3.5m, 4m, etc., and special heights can be customized according to the actual requirements to be suitable for the production of different concrete components. different concrete components production.

Formwork magnet height

Formwork magnet length

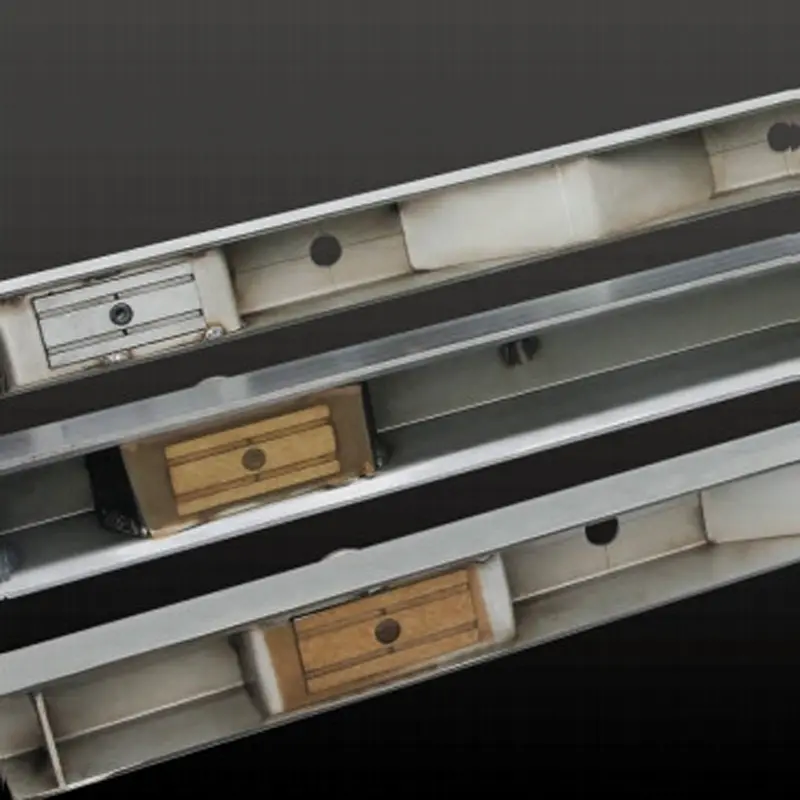

By means of the suction of the suction cups, the Magnetic formwork systems come into close contact with the platform, so that the component formwork system to be molded is held in place. Since the mold and the suction cups are a single unit, there is no positional movement, ensuring that the Shuttering system is not deformed. At the same time, the simple and quick operation of the suction cups makes the whole work safer and more stable. The suction cups can be pried up and the mold can be easily removed from the formwork platform with the help of the matching pry bar.

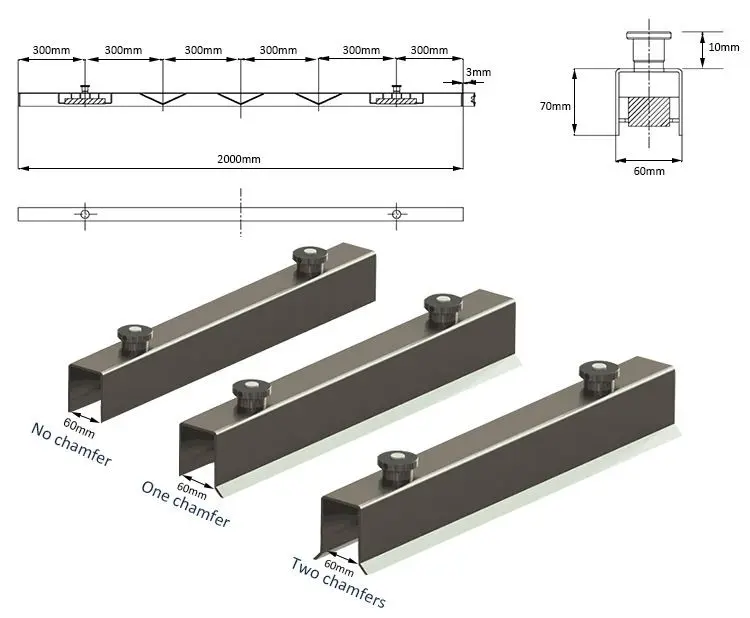

Since the suction cup system is located inside the steel formwork channel, concrete residue or other dirt will not damage the entire formwork system.Formwork magnet comes with a chamfering function, and chamfering can be customized according to requirements with 3 options.

Formwork magnet comes with a chamfering function with 3 options

With the booming development of global precast building industry, magnetic fixing products such as magnetic boxes and fixed magnetic holders have been fully used in the production process of precast concrete components, and Formwork magnet, because the magnetic block is directly embedded in the formwork of the production components, has the advantage of being more convenient, more efficient and more stable than the current magnetic box fixing.

QCM magnet has introduced the international advanced fiber laser cutting machine, electro-hydraulic servo numerical control bending machine and numerical control lathe, which can independently research and develop and produce magnetic edge molds of various sizes and suction force, and the 4-meter-long edge molds can be bent and shaped at one time, with high precision and excellent quality.

QCM has advanced production equipment

About us

QCM specializes in magnetic components and provides innovative solutions for magnetic applications. Our main products are Fishing magnets, Hook magnets, Shuttering system and its connecting accessories, Formwork magnets, Magnetic chamfering strips and all kinds of pre-fabricated magnetic holders.

Using our expertise in magnetic components and our rich experience in supporting the production of prefabricated components, we have developed a number of practical and innovative magnetic fixing products, our products have complete specifications, excellent quality, easy to operate, long service life, we can also quickly customize a variety of magnetic fixing parts according to the different needs of customers.

We are willing to share our expertise with you to help you solve your specific application needs for magnetic components.

QCM factory

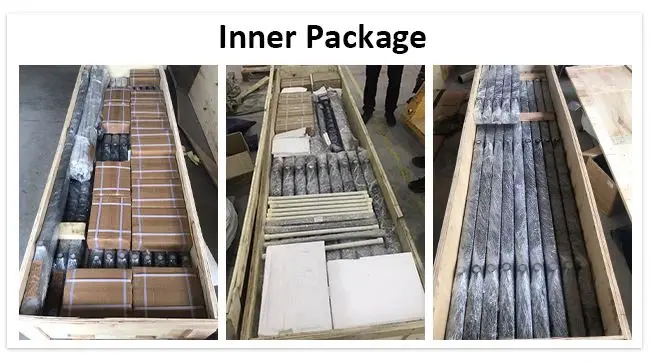

Packaging and transportation methods: