0102030405

Shuttering Magnets with Adapters

Shuttering magnets with adapters are an essential tool in the construction industry. Simply put, a shuttering magnet is a device that is used to hold metal forming systems, also called formwork, together. Formwork is a critical component of any construction project, as it is used to support and contain wet concrete or other materials during the hardening process.

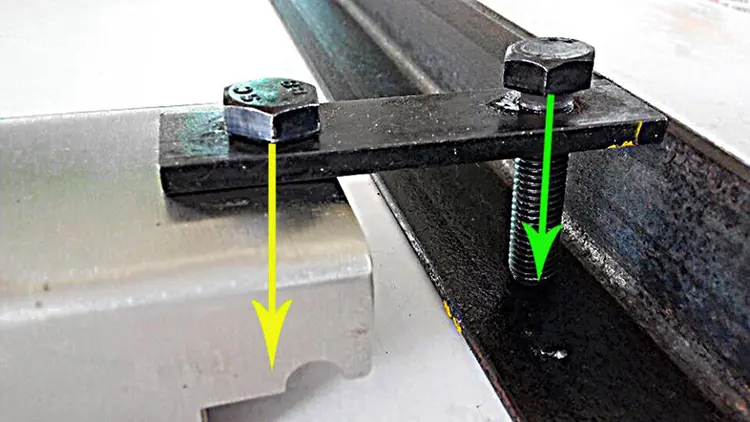

Step-type shuttering magnet with adapter usage scenario

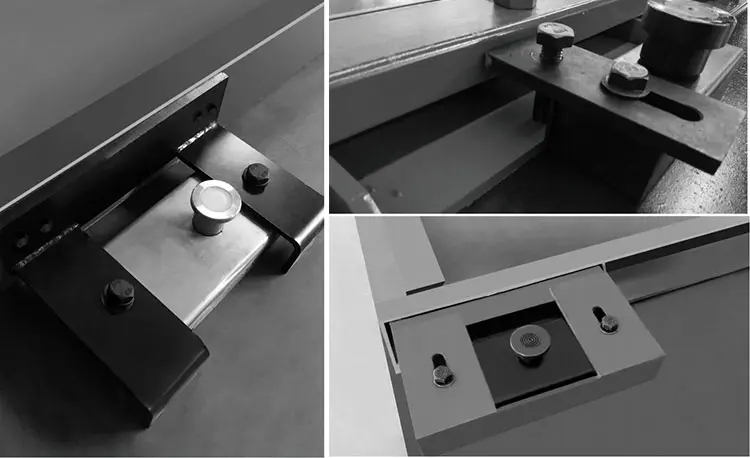

Shuttering magnets with adapters come in various sizes and strengths and work on a simple principal of attraction. The magnets are placed onto the metal formwork, and once activated, they hold the formwork in place securely. The adapter is a small, adjustable plate with a threaded hole that is attached to the formwork and used to align the magnet. Once the magnet is aligned with the adapter, it can be activated, and the formwork and magnet will become affixed to one another.

Applications of Shuttering Magnets with Adapters

The main advantage of using shuttering magnets with adapters is that it allows for a quick, easy, and safe construction process. These magnets are ideal for use in large construction projects when time is of the essence. The use of these magnets can increase efficiency in the construction process by reducing the time needed to erect or dismantle formwork, leading to savings in labor costs, and improving overall productivity.

Another advantage of using shuttering magnets with adapters is that they eliminate the need for traditional clamping methods, adding an extra layer of safety to the construction area. Shuttering magnets are also very durable and made of high-quality materials, making them an excellent investment for any construction project.

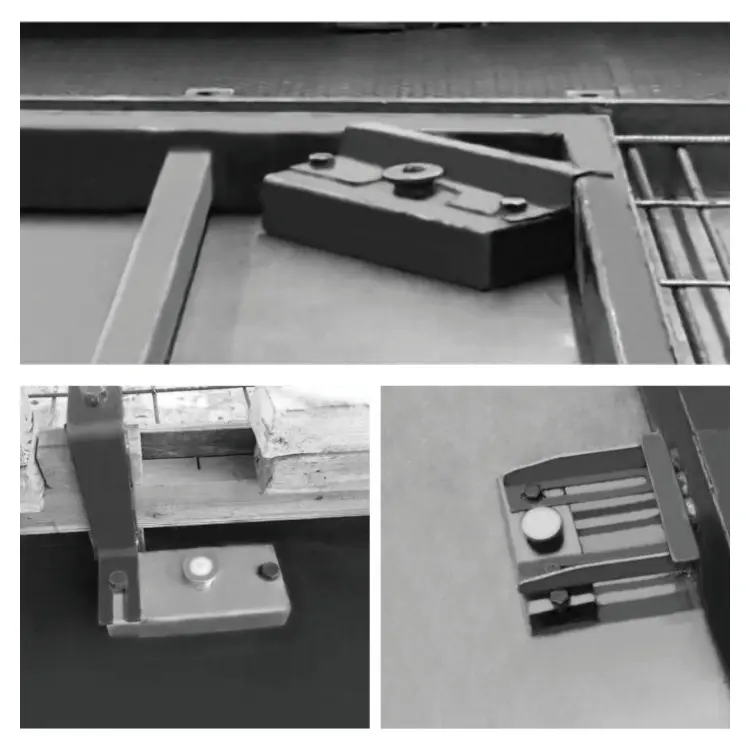

Application of Precast Concrete Formwork Clamps For Shuttering Magnet

In conclusion, shuttering magnets with adapters play a crucial role in the construction industry. They are not only a time-saving tool but also a safer and more efficient option for formwork. With their simplicity, strength, durability, and adaptability, they are quickly becoming the preferred choice in construction sites worldwide.