0102030405

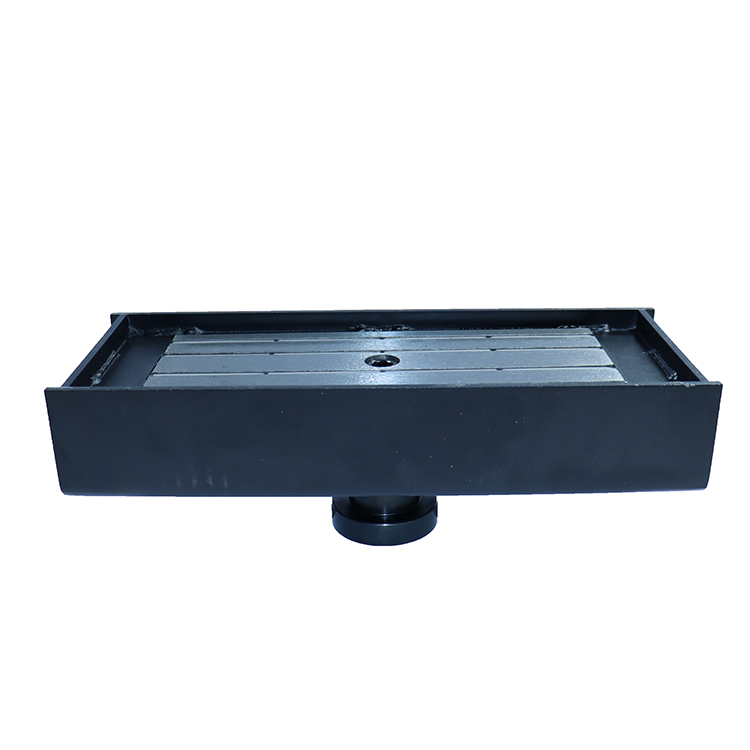

Shuttering magnet for precast concrete formwork

Shuttering magnets are a handy tool for precast plants to hold forms in place while pouring concrete elements. These magnets provide a more efficient and faster alternative to traditional bolting or welding. Alternatively bolting or welding can damage the formwork and pouring surface.

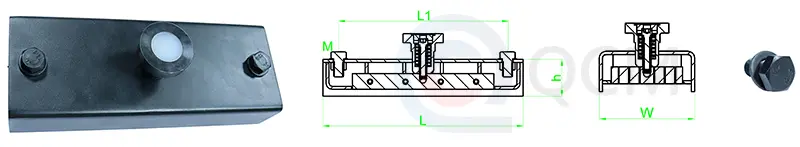

| |||||||

Model |

L(mm) |

L1(mm) |

W(mm) |

h(mm) |

M |

(g) Weight |

(kg) Breakaway |

QCM450 |

170 |

135 |

60 |

43 |

M12*30 |

1800 |

450 |

QCM600 |

170 |

142 |

60 |

43 |

M12*30 |

2500 |

600 |

QCM900 |

280 |

244 |

60 |

43 |

M12*30 |

2800 |

900 |

QCM1600 |

290 |

240 |

120 |

60 |

M16*30 |

6500 |

1600 |

QCM1800 |

320 |

270 |

120 |

60 |

M16*30 |

7200 |

1800 |

QCM2100 |

320 |

270 |

120 |

60 |

M16*30 |

7600 |

2100 |

QCM2400 |

320 |

270 |

120 |

60 |

M16*30 |

7600 |

2400 |

QCM3000 |

320 |

270 |

140 |

60 |

M16*30 |

7800 |

3000 |

How Shuttering Magnets Work

Shuttering magnets are made up of a number of components, including

- Neodymium magnet: This is a powerful permanent magnet that provides a strong magnetic force that is essential for holding the stencil firmly in place.

- Steel Case: The magnet is encased in a steel case that serves multiple purposes:

- It protects the magnet from damage caused by impact.

- The steel casing does not seal the bottom surface, this design helps to concentrate the magnetic force at the bottom and maximize adhesion to ferrous surfaces.

- It facilitates handling and positioning of the magnet.

- CONTROL MECHANISM: Shuttering magnets have an on/off button. When the button is pressed, the magnet adheres firmly to the cast steel table. Lifting the button with the special pry bar will release the magnetic force and the magnet will separate from the steel platform.

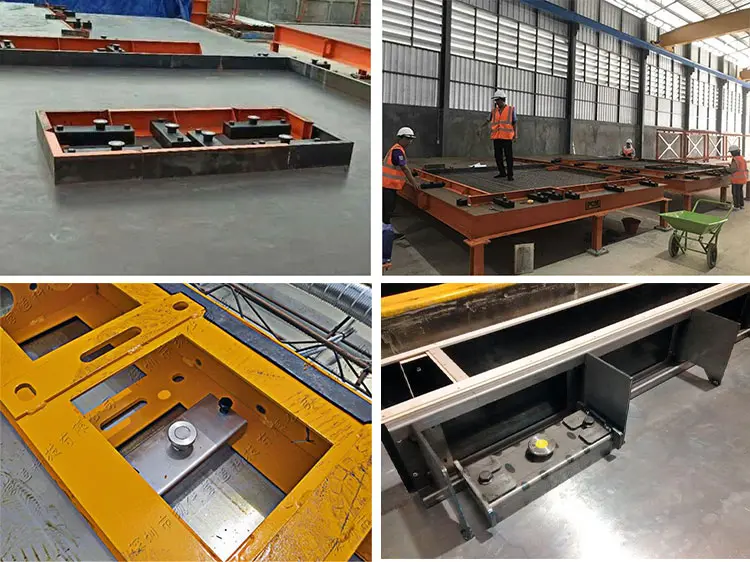

Procedure

1. Placement: Place the shuttering magnet on the side of the formwork with the bottom surface fitting the steel platform.

2. Activate: Tap the button at the top with a mallet or rubber mallet to activate the magnet's strong adsorption.

3. Concrete Pouring: Check whether the formwork is firmly fixed, after confirming the completion, you can start pouring concrete without worrying that the formwork will move under the pressure of concrete.

4. DISCONTINUATION: Once the concrete has set, the magnet can be separated by lifting the button using the release lever to make it easier to remove the shuttering magnet from the pouring table.

5.STORAGE AND MAINTENANCE: After using the shuttering magnet, clean and lubricate it to prevent rust.

Advantages of shuttering magnets

- Efficiency: Using shuttering magnets to hold the template in place dramatically reduces work time.

- Surface protection: Using shuttering magnets to secure formwork avoids damaging the pouring surface by welding or bolting.

- Versatility: Shuttering magnets with adapters can be used to fix formwork made of wood, aluminum and steel.

- High load-bearing capacity: The different types of shuttering magnets offer different levels of adsorption force, from 450kg to 3000kg, a characteristic that makes the magnets suitable for a wide range of prefabrication scenarios.

- Durability: With proper use and attention to maintenance, shuttering magnets will have a long lifespan, which can greatly increase the reuse rate.

The use of shuttering magnets for securing concrete forms in precast construction is an innovative solution that increases efficiency and reduces damage caused by traditional fastening methods.