shuttering magnet for concrete formwork

product detail

Shuttering magnets, also known as precast concrete magnets or magnetic formwork systems, are professional fixing tools used in precast plants. These magnets help workers to efficiently fix and position the formwork, thereby improving the production efficiency and finished product accuracy of precast parts.

Functionality and Design

The Shuttering Magnet is mainly composed of a sturdy steel housing and a neodymium magnet array. It is designed with an on/off mechanism for quick installation and removal. This design allows for easy release of the magnetic force, making it easy to move the magnet and position the template as needed, which is essential for efficient fixing and alignment of the template.

Specification of precast concrete magnets

|

Model |

L(mm) |

L1(mm) |

W(mm) |

h(mm) |

M |

Breakaway(lbs) |

Breakaway(kg) |

|

QCM450 |

170 |

135 |

60 |

43 |

M12*30 |

1000 |

450 |

|

QCM600 |

170 |

142 |

60 |

43 |

M12*30 |

1300 |

600 |

|

QCM900 |

280 |

244 |

60 |

43 |

M12*30 |

2000 |

900 |

|

QCM1600 |

290 |

240 |

120 |

60 |

M16*30 |

3500 |

1600 |

|

QCM1800 |

320 |

270 |

120 |

60 |

M16*30 |

4000 |

1800 |

|

QCM2100 |

320 |

270 |

120 |

60 |

M16*30 |

4600 |

2100 |

|

QCM2400 |

320 |

270 |

120 |

60 |

M16*30 |

5300 |

2400 |

Key Features:

- Powerful Magnetism: Depending on the model, the magnets’ adhesive strength varies from 450 kg to over 3,000 kg which is critical for providing stability when concrete is poured.

- Multiple Uses: Shuttering magnets work with any and all formwork materials including plywood, aluminum, and steel. They can also be used for a great variety of precast elements like wall panels, stairs, and balconies.

- Simplicity: The magnets’ integrated button mechanism makes it easier for workers to turn the magnetic force on or off and increases efficiency for construction projects.

Advantages:

- Increased Efficiency: Labor costs and time are cut down drastically because formwork does not need to be bolted or welded and can be secured with shuttering magnets.

- Improved Quality Control: The aforementioned magnets as powerful as these professionally crafted ones they aid in holding the formwork at its correct position, thus providing reinforcement of higher quality concrete products.

- Reusability: Over time, shuttering magnets will help to cut overall cost as they are designed to be easily fastened and removed multiple times.

Applications in Construction

Shuttering magnets have gained acceptance in the different areas of precast concrete production as follows:

- Building and Erection of Walls and Columns: Before construction of walls and columns, they are pivotal in keeping formwork holding devices in position during concrete pouring.

- Modular Construction: Shuttering magnets make it possible to quickly construct modular dwellings as they allow recording and undoing of formwork in a great length.

- General Works: In general construction projects, these magnets allow speedy construction and disassembly of formworks systems, thus shortening the duration of many projects.

Application of shuttering magnets

In conclusion, shuttering magnets contribute significantly towards increased productivity, quality assurance, and decreased manpower utilization in the precast concrete industry. The unparalleled efficiency and effectiveness of shuttering magnets make them essential tools for contractors looking to improve business productivity and reduce costs.

QCM magnet precast concrete magnets production equipment

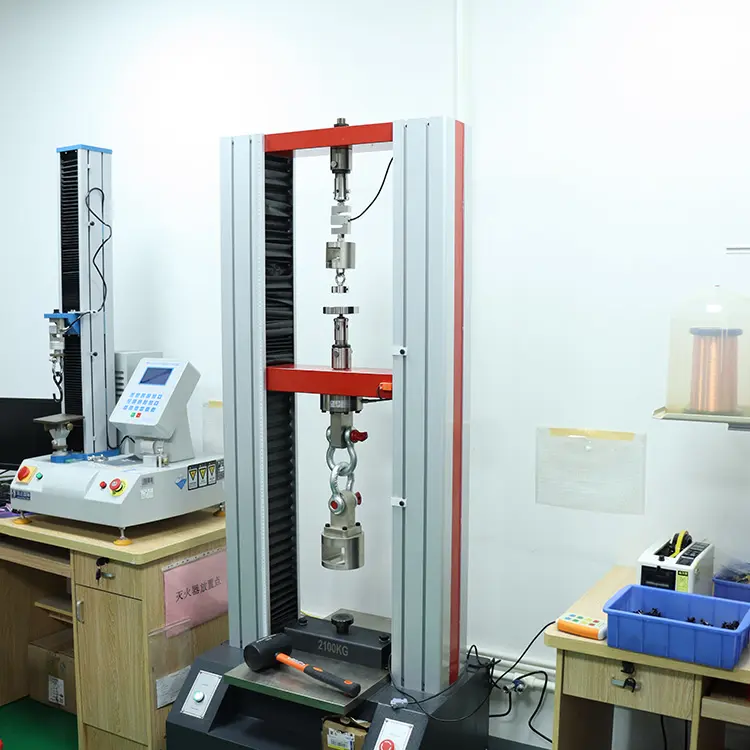

QCM magnet shutting magnet box pull force test equipment

Our factory