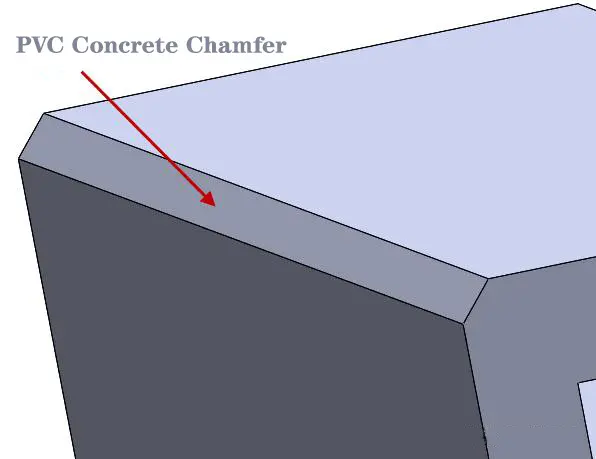

PVC Concrete Chamfer

Technical Parameters of PVC Concrete Chamfer

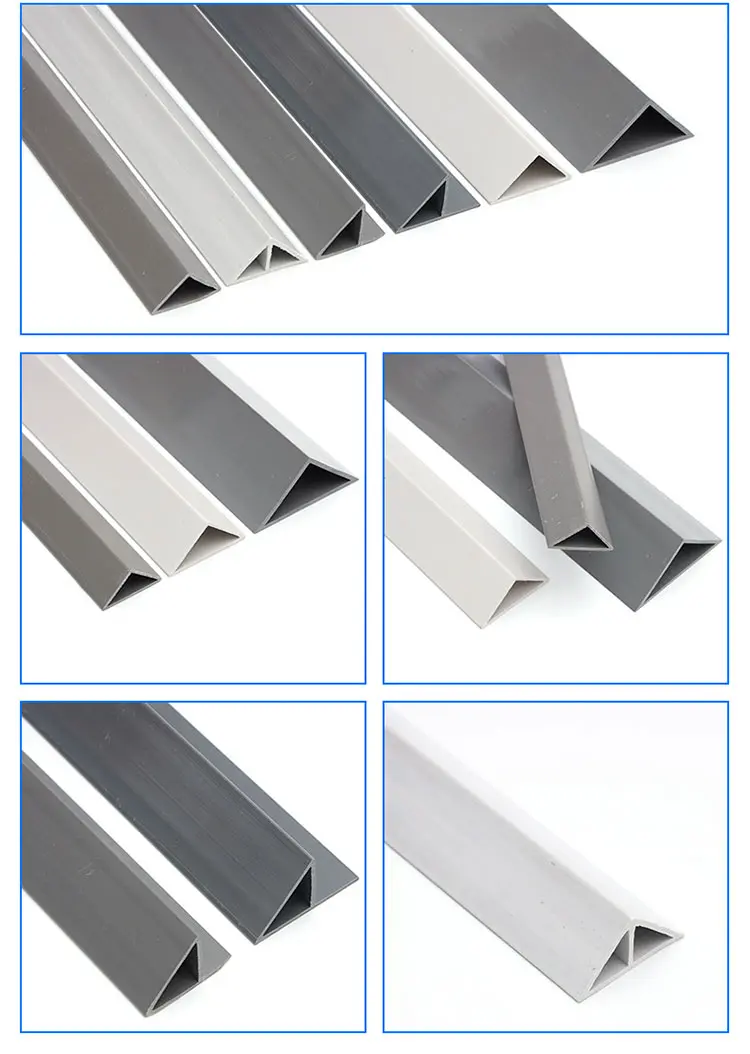

Size Specifications

Width: Available widths range from 10 mm to 50 mm, allowing for different degrees of chamfering. For example, a 15 - mm - wide chamfer strip is used for standard - sized columns and walls in residential construction, while wider strips like 30 mm preferred for large - scale commercial or industrial concrete structures.

Thickness: The thickness of PVC Concrete Chamfer strips generally varies between 2 mm and 6 mm. Thicker strips, such as 5 - 6 mm ones, are more suitable for applications where higher durability and resistance to deformation during the concrete - pouring process are required, like in the construction of bridge piers.

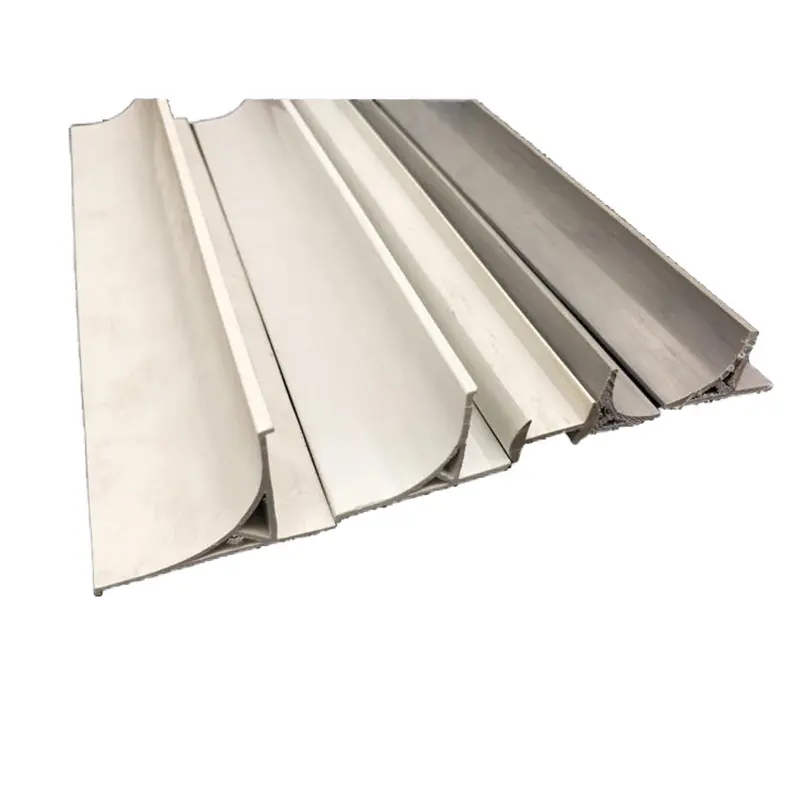

Length: Standard lengths can be 2 meters, 3 meters, or customized according to project needs. Long - length strips are beneficial for continuous chamfering in long - wall construction, reducing the number of joints and ensuring a more seamless finish.

Physical Properties

Density: The density of the PVC material used in these chamfer strips is around 1.3 - 1.4 g/cm³. This density provides a good balance between light - weight for easy handling and sufficient mass to maintain stability during installation and concrete pouring.

Flexural Strength: It has a flexural strength of approximately 70 - 100 MPa. This high flexural strength enables the chamfer strips to maintain their shape under the pressure exerted by wet concrete and during the vibration process in concrete placement, ensuring accurate chamfer formation.

Tensile Strength: The tensile strength of PVC Concrete Chamfer strips is in the range of 40 - 60 MPa. This property ensures that the strips do not tear or break when being bent or stretched during installation on complex - shaped formworks.

Chemical Properties

Weather Resistance: PVC is highly resistant to UV rays and various weather conditions. It can withstand long - term exposure to sunlight, rain, and temperature fluctuations without significant degradation. Outdoor concrete structures with PVC chamfer strips can maintain their appearance and performance for up to 10 - 15 years under normal climate conditions.

Chemical Resistance: It shows excellent resistance to most common chemicals found in the construction environment, such as alkalis and acids present in concrete admixtures. This chemical resistance ensures that the chamfer strips do not react with the concrete components, maintaining their integrity and functionality throughout the service life of the concrete structure.

key features and functions of PVC Concrete Chamfer