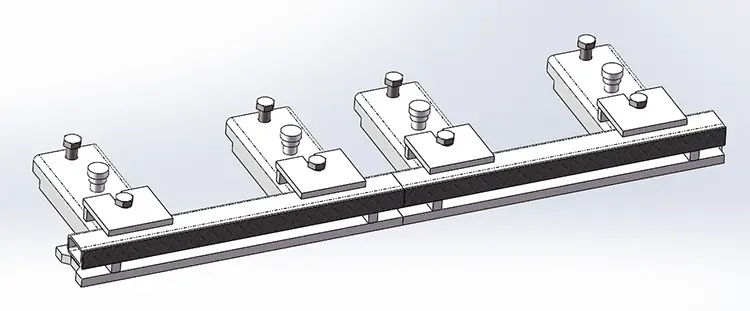

Precast concrete magnet with magnetic adapter

product detail

Adapters are essential components used in conjunction with precast concrete magnets to facilitate efficient handling and positioning of formwork in precast concrete production. Here are the key points about adapters for precast concrete magnets:

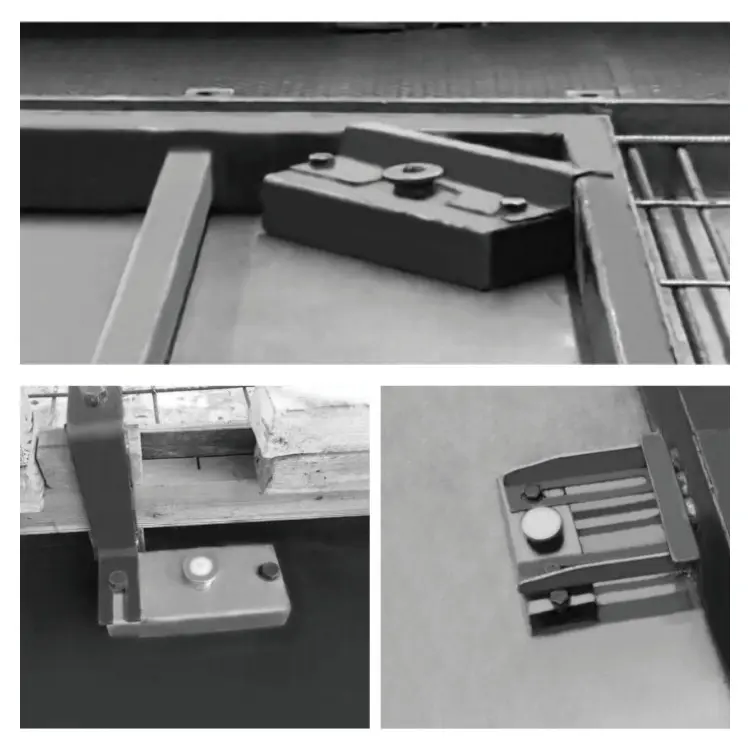

Purpose and Benefits of Adapters

- Adapters provide a secure connection between the precast concrete magnets and the formwork, ensuring a tight fit for shear resistance during concrete pouring and vibration.

- They allow for precise calibration of the formwork position before activating the magnets, improving accuracy and efficiency.

- Adapters enable the use of precast concrete magnets with various types of formwork, including steel and wooden forms.

- By optimizing the connection between magnets and formwork, adapters help maximize the holding force of the magnets.

adapters help maximize the holding force of the magnets

Types and Applications of Adapters

- Shuttering magnets with adapters are used to fasten the shuttering box magnet with precast side molds for shear resistance.

- Adapters can be used for fixing fibrous concrete upstands for balconies, parapets, and wooden formwork.

- They are also employed in the production of precast floor plates, double walls, and for fixing windows and doors.

- Adapters can be designed to clamp two upstands simultaneously and remain stable during vibration and demolding processes.

Applications of Adapters

Design and Features of Adapters

- Adapters are typically made from carbon steel or other durable materials.

- They feature two-sided threads (e.g., M12, M16, M18) for easy assembly into the precast concrete magnets.

- Some adapters have an adjustable clamping range to accommodate various formwork thicknesses.

- Compact and robust designs allow for versatile use and minimize space requirements on the casting bed.

In summary, adapters are essential accessories that enhance the functionality and efficiency of precast concrete magnets by providing a secure and adjustable connection between the magnets and formwork. They contribute to improved accuracy, reduced setup times, and optimized holding force in precast concrete production.