0102030405

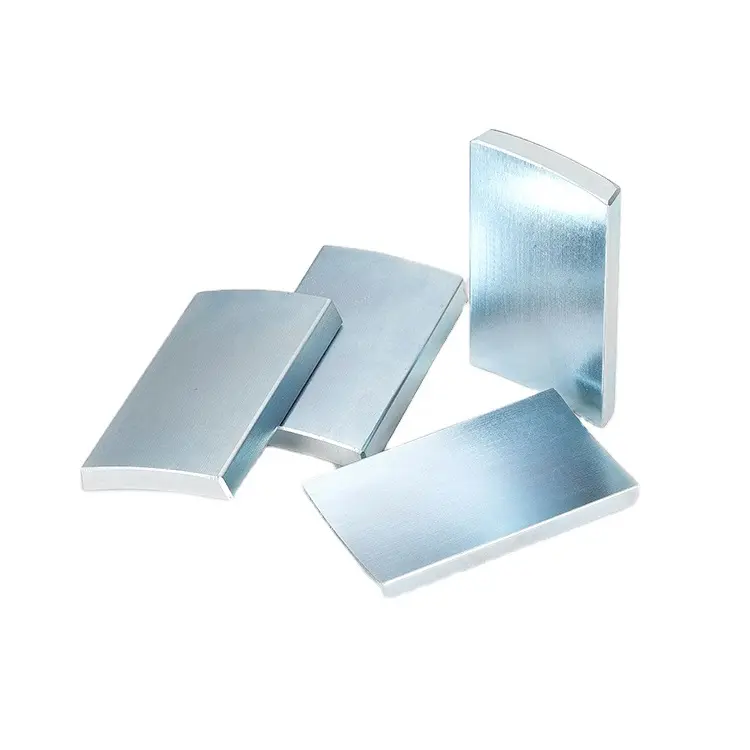

Permanent Rare Earth NdFeB Ni Coating Motor Custom Magnet for Industrial

Description

First of all, the production material of the magnetic ring is generally ferrite magnetic material. They have the characteristics of high permeability, high saturation flux density and low hysteresis loss, so that the magnetic ring has strong magnetic properties and good magnetic permeability, thus providing a solid foundation for the use of components.

Secondly, according to the specific shape and size requirements of the magnetic ring, the corresponding mold is selected for stamping, usually using a pressure punch for stamping. When stamping, the magnetic material sheet needs to be pressed into the right shape first, and then the secondary stamping is carried out in the mold, the edge of the magnetic ring is trimmed and smooth, and the treatment is carried out to ensure its dimensional accuracy and surface finish.

Finally, the stamped magnetic ring also needs to be baked and annealed at high temperatures to eliminate the residual stress inside the material and improve the magnetic permeability and permeability of the alloy. Through this series of process steps, the magnetic ring manufacturing process is completed.

In summary, the production process of the magnetic ring needs to be completed through a number of processes, including material selection, mold design, stamping and baking. Each step requires delicate operation and technical treatment to ensure the quality and performance of the magnetic ring. As an important electromagnetic performance component, magnetic ring has a very wide range of applications, including electronic communication equipment, power transmission equipment, automobile manufacturing and other industries, and the production of magnetic ring has also brought a solid foundation for the development of these fields.