0102030405

Shuttering magnet for prefabricated building components

2024-11-06

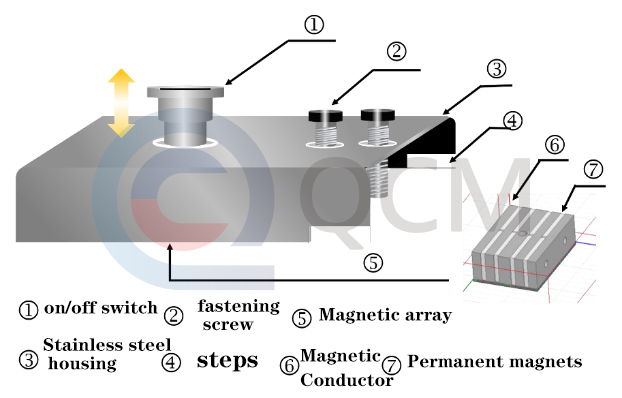

This assembly building component adopts a new generation of super-strong rare earth neodymium iron boron permanent magnet material, through the reasonable magnetic circuit design, so that precast concrete magnet in the working state to achieve a hundred kilograms or even tons of suction force. Developed for simplifying the installation of precast concrete component molds, it is aimed at solving the technical problems of destructive, difficult to dismantle and poor versatility of the traditional bolt anchoring to the mold table.

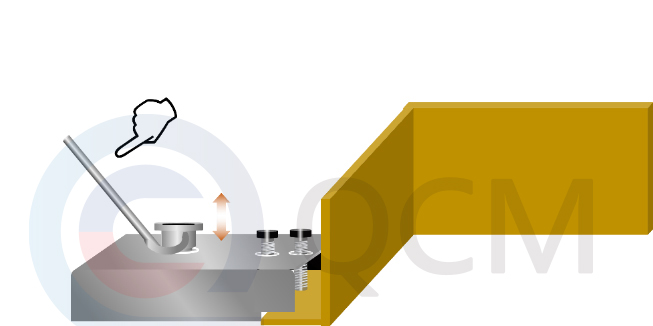

Release of precast concrete magnet

Technical Details

Research and development background:

If the future assembly building components to achieve industrialization, standardization and intelligent manufacturing, the key link requires flexible component molding mold disassembly, convenient and efficient, reusable, and universal. Shuttering magnet for assembled building components is developed to simplify the installation of precast concrete component molds, aiming at solving the technical problems of destructive, difficult to dismantle and poor versatility of the traditional bolt anchoring on the mold table.

Core technology:

Adopting a new generation of ultra-strong rare earth NdFeB permanent magnet material, through the reasonable magnetic circuit design, the precast concrete magnet in the working state to achieve hundred kilograms or even tons of suction force to achieve strong fixed function to meet the requirements of engineering applications, and to meet the requirements of the device can be easily moved in the closed state.

Application Prospects:

At present through the rare earth neodymium iron boron strong magnetic materials to achieve assembly building components fixed mold technology solutions are mainly used throughout the Middle East, Australia, South America, Russia and Southeast Asia and other countries and regions, and can design and manufacture PC components with shutter magent companies are mainly concentrated in the assembly building technology leading Germany, the United States, and magnetic materials and magnets exported to China. According to incomplete statistics, assembly building components PC components of various types of molds annual market size of about 500 million, and the use of magnetic fixtures accounted for about 20% of the market, i.e., enterprise-level market size of 100 million, enterprise-level sales of 25 million (accounting for 25%), a conservative estimate of the magnetic fixtures program margins of up to 50% that is 12.5 million.

shutter magnet construction diagram

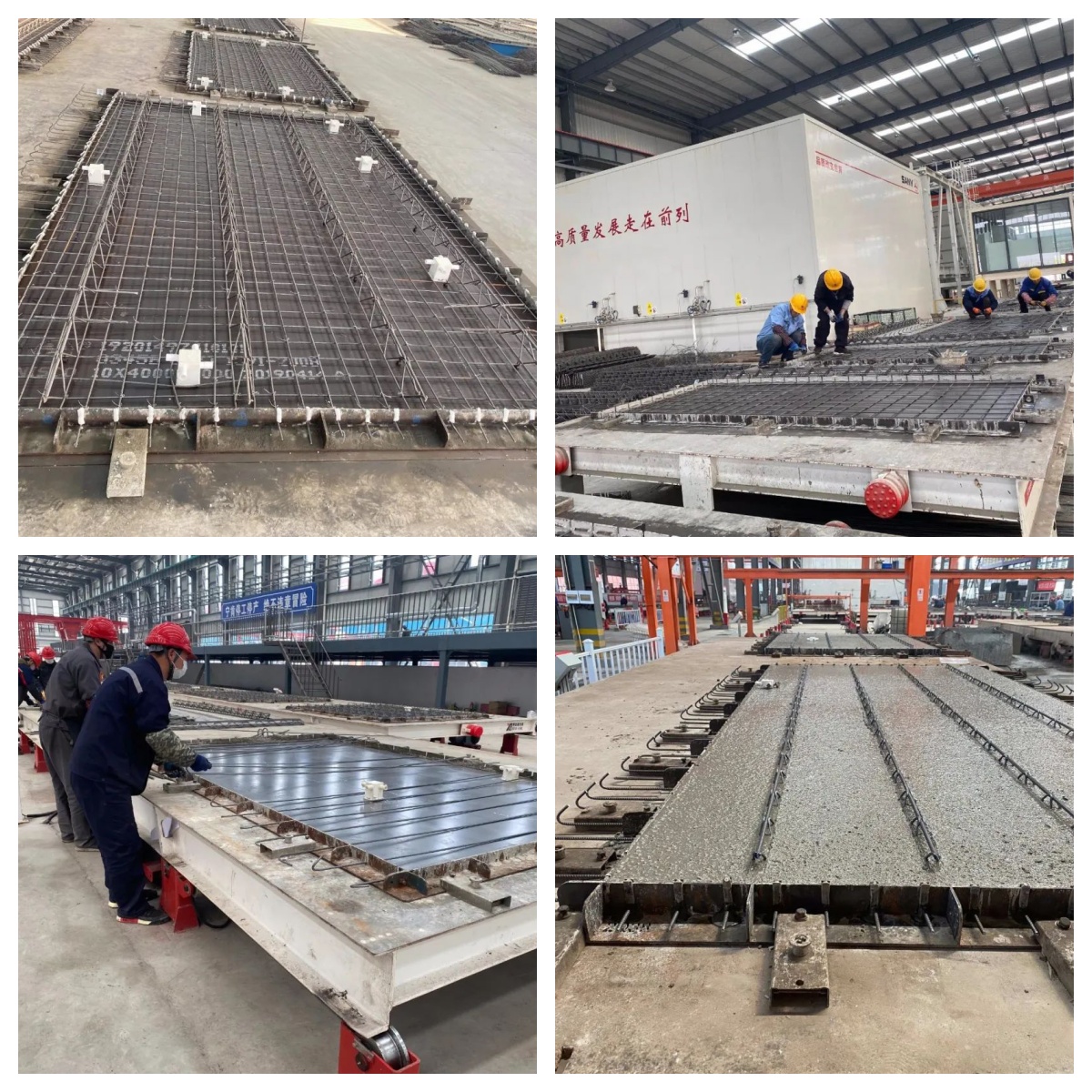

Application of precast concrete magnet

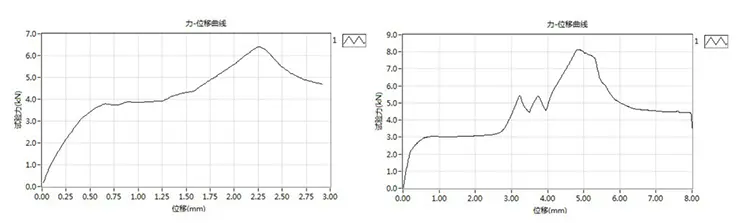

Pull Force Test of Precast Concrete Shuttering Magnets