Production organization and quality control of PTW wall

PTW wall production emphasizes quality control following Chinese and Korean standards, with strict material selection, precision in steel truss and mold design, and precise positioning techniques for embedded parts and A plates, ensuring high-quality prefabricated concrete structures.

1. PTW wall production organization and quality control

1.Production and installation

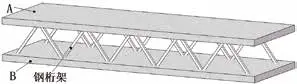

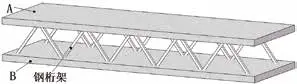

PTW production: (1) Processing of steel trusses and embedded parts (commissioned processing); (2) Production of A plates and B plates (partitioned production); (3) Waterproofing of finished products (commissioned processing)

2.Key points of PTW quality control

PTW wall panel quality requirements: Chinese standards GB 50010-2010 "Concrete Structure Design Code", GB 50666-2011 "Concrete Structure Engineering Construction Code", GB 50204-2015 "Concrete Structure Engineering Construction Quality Acceptance Code", GB/T 50107-2010 "Concrete Strength Inspection and Evaluation Standard", GB 50164-2012 "Concrete Quality Control Standard", GB 50119-2003 "Technical Specification for Application of Concrete Admixtures", 15G367-1 "Precast Reinforced Concrete Slab Stairs", "Steel Structure Design Code".

Korean Standards "Standard Specifications for Construction Projects" Ministry of Land, Infrastructure and Maritime Affairs, "Special Specifications for Construction Projects in Seoul", JGJ 63-2006"PC Steel Pipe" KSD3505, JGJ 18-2012 "PC Hard Wire and Soft Hard Wire" KSD7002, JGJ 1-2014 "Rebar and Reinforcement Materials" A04030. Samsung Company Specifications (Enterprise Standards) "Samsung Electronics X2 Special Specifications PC Project", "Samsung Electronics X2 Special Specifications PTW Project".

2.1 Quality Control of Main Raw Materials

The main raw materials for the production of PTW walls include concrete, steel bars, steel mesh, truss steel bars, steel trusses and various embedded parts. This project has put forward high requirements for various raw materials.The raw materials for the production of PTW also include cement, admixtures, sand, stone, and admixtures. First of all, choose a raw material manufacturer with a certain production capacity to ensure the stability of the supplied materials, including color and various performance indicators. Each material should use raw materials from the same manufacturer and of the same specifications and models, and the sand and gravel should be from the same origin. The color change of each material will cause the color difference of the concrete components, and the addition of admixtures should not change the color of the concrete.Low-alkali cement should be used for cement, and the performance test: color, standard consistency, setting time, specific surface area, stability, compressive strength, and flexural strength indicators are qualified, and the standard deviation of each indicator test result is small.Fly ash should be selected from Class F I or II ash, and secondary processed and finely ground fly ash should not be used, which is easy to introduce impurities and affect the appearance quality. The loss on ignition of fly ash should be strictly controlled, because the loss on ignition affects the state and early strength of the concrete mixture, and it should be controlled at ≤5%.Mineral powder is not used or used less in plain concrete, because the hydration of mineral powder can easily cause the color of concrete to turn green, and it is more sensitive to the curing temperature. S95 grade mineral powder is generally used in concrete. The color of mineral powder varies greatly from manufacturer to manufacturer, and there may be differences from the same manufacturer. It should be tested and compared by car, and mineral powder of different colors is strictly prohibited from entering the site.The performance indicators of sand and gravel meet the standard requirements, especially the color, mud content, mud content, aggregate gradation indicators are qualified and the standard deviation of the test results is small, because the mud content, mud content, and aggregate gradation will affect the state of the concrete mixture, the color and volume stability of the concrete after hydration.Polycarboxylic acid water reducer is mostly used as an admixture. The addition of admixtures should not change the color of the concrete, and should not cause bubbles on the surface of the concrete. Car inspections of color, water reduction performance, slump loss, and air content should be done well.Therefore, concrete materials require concrete mix ratio tests in advance according to the C50 standard to determine the concrete mix ratio. Concrete raw materials such as sand, stone, and cement are all controlled according to the requirements of raw materials for plain concrete.Rebars, steel trusses, and steel meshes should formulate corresponding material entry acceptance standards in accordance with drawings and relevant technical standards. Steel trusses and embedded parts should formulate corresponding processing acceptance standards according to the types and functions of embedded parts.2.2 Precision control of steel trusses

See the allowable deviation and inspection method of Samsung composite steel trusses and the allowable deviation and inspection method of Samsung embedded parts.

Three-star composite steel truss size allowable deviation and inspection method |

Number | Inspection items | Allowable deviation/mm | Inspection methods |

1 | length | ±4 | Use a ruler to measure the two ends and the middle part, and take the value with the larger absolute value of the deviation |

2 | high | ±3 | Use a ruler to measure the two ends and the middle part, and take the value with the larger absolute value of the deviation |

3 | width | ±3 | Use a ruler to measure 8 positions in the width direction of the steel truss and take the value with the larger absolute deviation |

4 | Lateral bending | 5 | Pull the wire and measure the maximum bend with a steel ruler |

5 | Flatness in height and length | 4 | Place a ruler on the length and width surfaces of the steel truss to measure the maximum gap between the surfaces. |

6 | Weld seam | | Inspection according to drawing requirements |

Samsung embedded parts size tolerance and inspection method |

Number | Inspection items | Allowable deviation/mm | Inspection methods |

1 | Dimensions | ±2 | Measuring with a ruler |

2 | Weld seam | | Inspection according to drawing requirements |

3 | Verticality of embedded bolts | 1 | Measuring with a square |

4 | The center position of the embedded bolt is offset | 2 | Use a ruler to measure the centerline position in both the vertical and horizontal directions and take the larger value |

2.3 Mould design and acceptance

See the allowable deviation and inspection method of prefabricated component mould dimensions.

Permissible deviation and inspection method of prefabricated component mould dimensions |

Number | Inspection items and contents | Allowable deviation/mm | Inspection methods |

| W6m | 1,-2 | |

1 | Length >6m and W12m | 2,-4 | Use a steel ruler to measure the height direction of the parallel component and take the point where the absolute value of the deviation is the largest. |

| >12m | 3,-5 | |

2 | Width, height (thickness) | 1,-2 | Use a steel ruler to measure the two ends and the middle, and take the point where the absolute value of the deviation is the largest |

3 | Bottom mold surface flatness | 2 | Measure with a 2M ruler and a feeler gauge |

4 | Diagonal difference | 3 | Use a steel ruler to measure the horizontal and vertical diagonals |

5 | Lateral bending | L/1500, and W5 | Pull the wire and use a steel ruler to measure the maximum lateral bending point |

6 | Warping | L/1500 | Double the distance between the intersection points of the diagonal line measurement |

7 | Assembly gap | 1 | Use a feeler gauge to measure and take the maximum value |

8 | Height difference between end mold and side mold | 1 | Measure with a steel ruler |

2.4 Positioning of embedded parts

PTW wall panel embedded parts include hoisting, connection, positioning, etc., with many types, large quantities and high precision requirements, so accurate positioning is also one of the difficulties in production. You can increase the accuracy of positioning by adding positioning tooling to the mold. Open holes at the positions where embedded parts need to be embedded on the mold platform, and use bolts to fix the embedded parts on the mold platform.

2.5 Positioning of A plate

PTW wall panels need to position A plate when making B plate. The positioning accuracy of A plate directly affects the accuracy of the entire PTW. A positioning device needs to be set up to realize the horizontal and vertical movement of A plate. When using, first hoist A plate above the mold platform to realize the rough adjustment of A plate position, and then use the positioning device for precise adjustment. After the adjustment is completed, use the inspection ruler for inspection to realize the precise positioning of A plate.

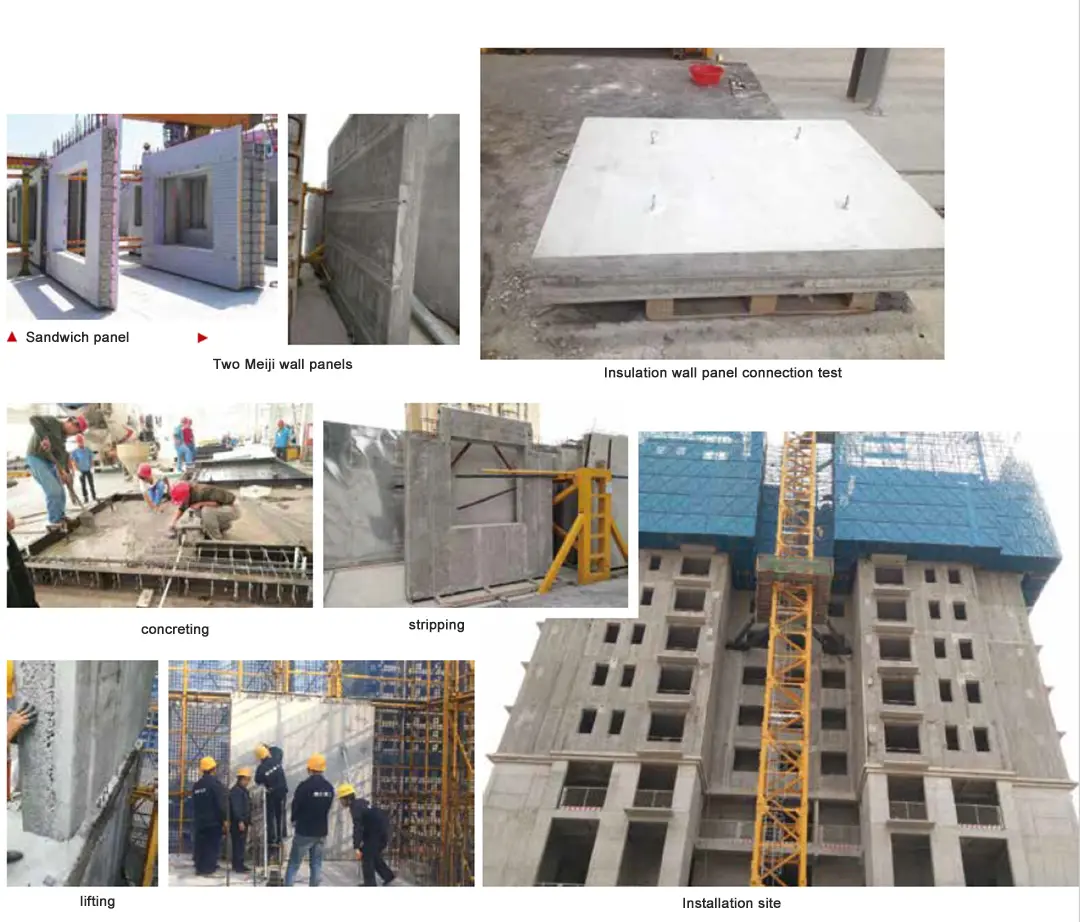

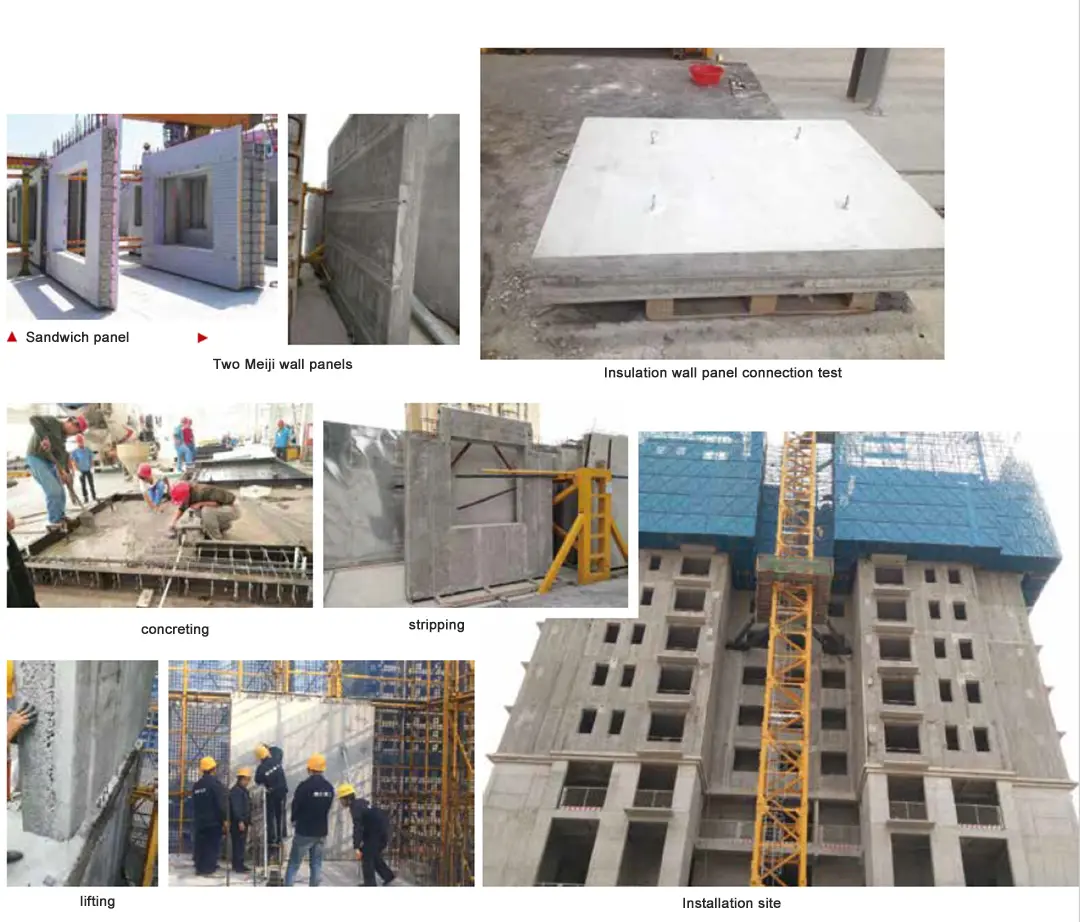

Application of "Ermingzhi" thermal insulation integrated exterior wall panels

1.Project Overview

Project Name: Hutuo Village Public Rental Housing Project. This project is a high-rise residential building with 2 underground floors and 23 above-ground floors. The prefabricated components included are shear walls, infill walls, beams, composite slabs, stair slabs, air conditioning panels and balcony slabs.

2.Advantages

(1)By using lightweight and thermally insulating foam concrete to replace part of the traditional concrete, the amount of concrete is reduced, the dead weight is small, the thermal insulation performance is good, and the production cost is reduced compared to traditional prefabricated concrete wall panels.

(2)Compared with the "sandwich" wall panels, the production process is reduced, the thermal insulation connectors are reduced, and the production cost of prefabricated components is reduced.

(3)The use of cement-based thermal insulation materials can achieve the same life of the thermal insulation materials and the structural walls, and the fire resistance of the thermal insulation layer is greatly improved.

3.Obtained utility model patent certificate

Utility model name: a prefabricated composite wall panel; Inventors: Liu Haoqiang, Peng Yonggang, Quan Hao, Yang Baodi; Patent number: ZL 2017 2 1098007.7; Patentee: Xi'an Jiancon Industry Co., Ltd.; Authorization announcement date: May 29, 2018; Authorization announcement number: CN 207419839 U.