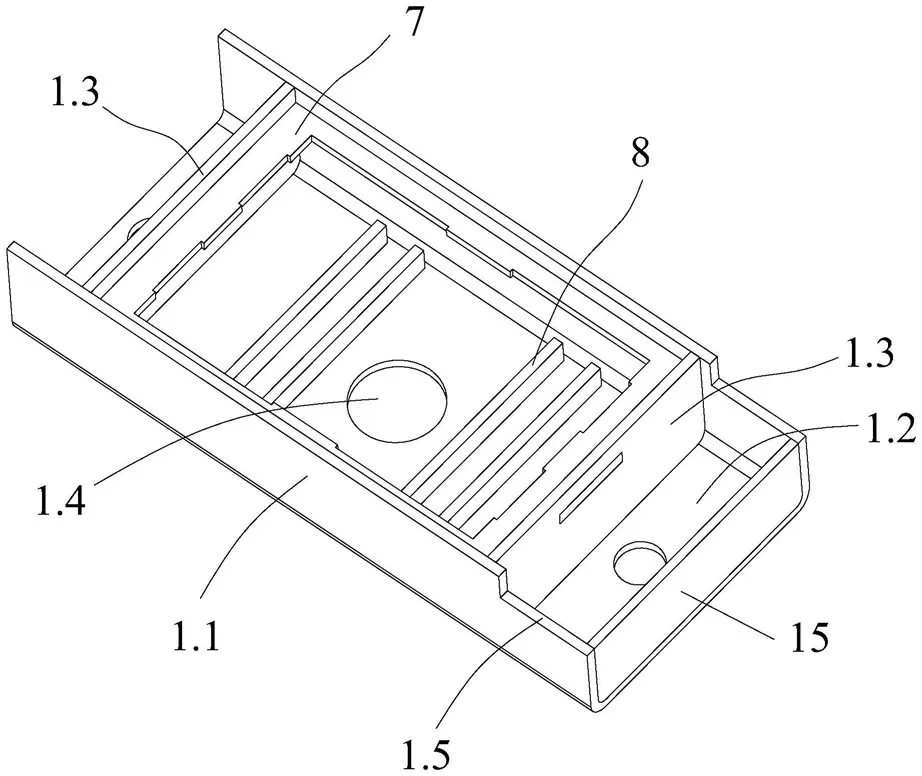

Magnetic fixing device for prefabricated component molds for construction Background technology

2024-11-05

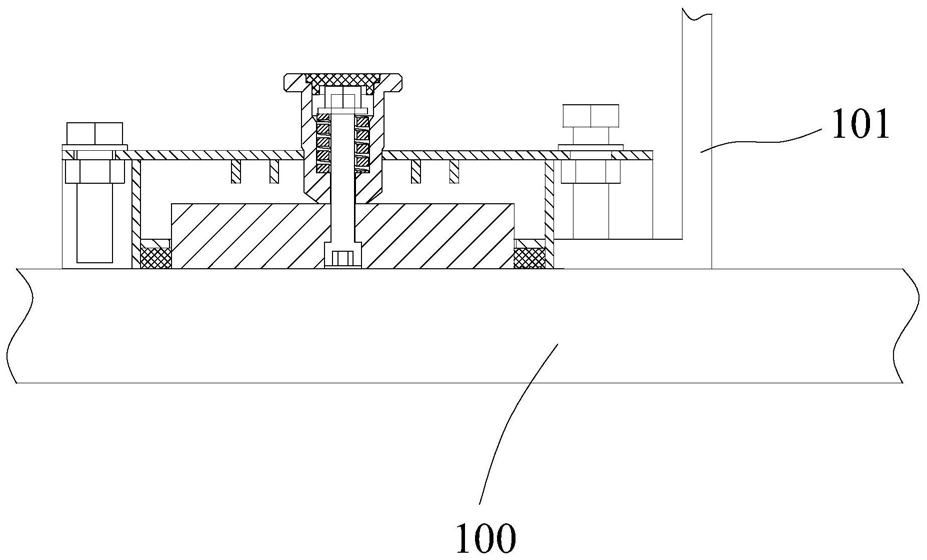

In the prefabricated building construction process to make prefabricated components for construction, you need to fix the mold on the steel platform, the traditional method is generally used to fix the mold by bolting, this fixing method will destroy the flat steel platform, under normal circumstances are not allowed to punch and tap or weld the bumps on the steel platform, because once the flatness of the steel platform has been destroyed, it will affect the quality of the prefabricated components when it is reused. The quality of the prefabricated component increases the difficulty of detachment, and also causes material waste, disassembly is time-consuming and laborious, and brings losses to the whole production line.

Existing technology, designed a magnetic fixed parts (precast concrete magnet) to replace the original bolt connection program, the use of precast magnet fixed although solved the original damage to the steel platform defects, but there are still problems: due to the existing technology shutter magnet shell is generally through the stainless steel plate, etc. Welding and become, so its bottom surface and steel platform contact surface is not easy to do very flat; and the existing shuttering magnet in the magnet assembly around the side wall with the shell there is a gap between the precast magnets in use, the mud will be from the bottom of the magnet shuttering and the platform gap into, and the mud will be from the magnet assembly around the gap into the precast magnets, and the mud will be from the magnet assembly around the gap into the precast magnet. Gap into the precast concrete shuttering magnets cavity, will produce a certain degree of wear and corrosion of the magnet assembly, time magnet assembly suction surface accumulation of a layer of mud, resulting in can not be affixed with the platform, seriously reduce the suction between the magnet assembly and the platform; and when the mud filled into the precast concrete And when the mud fills into the cavity of the precast concrete magnet, it will cause the up and down movement of the magnet assembly in the cavity to be stuck or even unable to move, resulting in the precast wall production magnet not being able to be used.