How do Magnets Work?

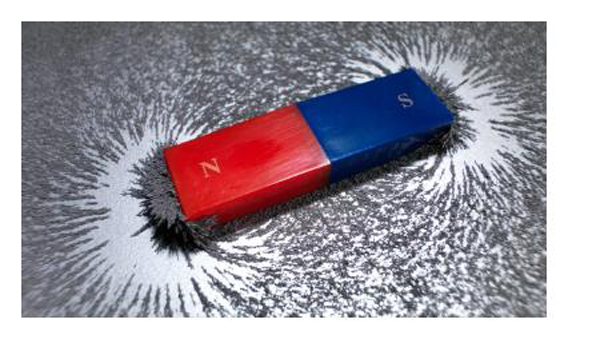

The magnetic field is created by the alignment of the magnetic moments in the material, which are microscopic north and south poles that generate a magnetic force.

In a permanent magnet, such as a bar magnet, the magnetic moments are aligned in a specific direction, so the magnetic field is strongest at the poles and weakest at the center. When placed near a magnetic material, the magnetic field exerts a force on the material, either attracting or repelling it depending on the orientation of the magnetic moments.

In an electromagnet, the magnetic field is created by an electric current flowing through a coil of wire. The electric current creates a magnetic field that is perpendicular to the direction of the current flow, and the strength of the magnetic field can be controlled by adjusting the amount of current flowing through the coil. Electromagnets are widely used in applications such as motors, speakers, and generators.

The interaction between magnetic fields and electric currents is also the basis for many technological applications, including generators, transformers, and electric motors. In a generator, for example, the rotation of a magnet near a coil of wire induces an electric current in the wire, which can be used to generate electrical power. In an electric motor, the interaction between the magnetic field of the motor and the current flowing through the coil of wire creates a torque that drives the motor's rotation

Types of Permanent Magnets

Permanent magnets can be classified into several types based on their composition, magnetic properties, and manufacturing process. Here are some of the common types of permanent magnets:

1.Neodymium magnets: These rare earth magnets are composed of neodymium, iron, and boron, and are the strongest type of permanent magnets available. They have high magnetic energy and can be used in a variety of applications, including motors, generators, and medical equipment.

2.Samarium cobalt magnets: These rare earth magnets are composed of samarium, cobalt, iron, and copper, and are known for their high-temperature stability and corrosion resistance. They are used in applications such as aerospace and defense, and in high-performance motors and generators.

3.Ferrite magnets: Also known as ceramic magnets, ferrite magnets are composed of a ceramic material mixed with iron oxide. They have lower magnetic energy than rare earth magnets, but are more affordable and widely used in applications such as speakers, motors, and refrigerator magnets.

4.Alnico magnets: These magnets are composed of aluminum, nickel, and cobalt, and are known for their high magnetic strength and temperature stability. They are often used in industrial applications such as sensors, meters, and electric motors.

5.Bonded magnets: These magnets are made by mixing magnetic powder with a binder, and can be manufactured into complex shapes and sizes. They are often used in applications such as sensors, automotive components, and medical equipment.

The choice of permanent magnet type depends on the specific application requirements, including the required magnetic strength, temperature stability, cost, and manufacturing constraints.