0102030405

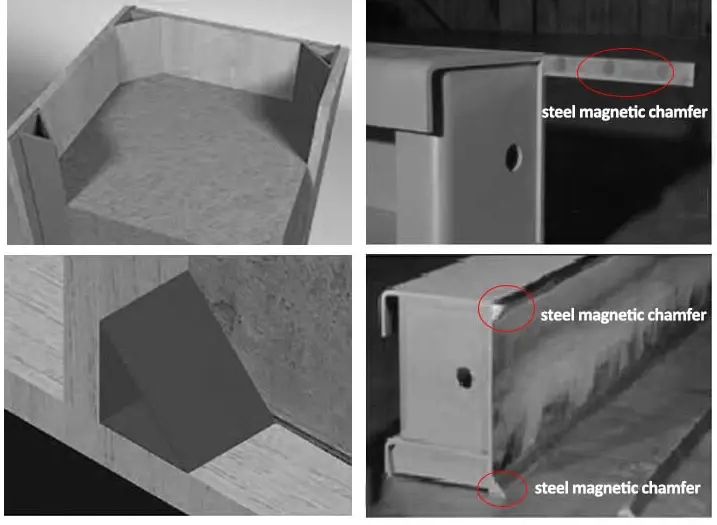

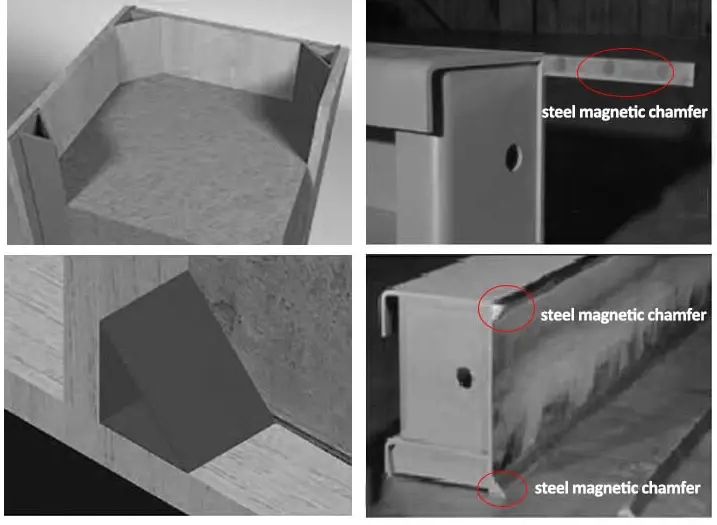

magnetic steel chamfer strip for concrete precast formworks

The magnetic steel chamfer strip features a magnet embedded in its surface, which is clearly visible. It is designed for use with steel beds, steel panels, and bulkheads to create chamfered edges on the corners and surfaces of concrete wall panels and small concrete items. Constructed from A3 steel and equipped with powerful neodymium magnets, the magnetic steel chamfer strip is both reusable and highly durable. As long as the magnetism remains strong, it can be used repeatedly. The robust magnets securely hold the chamfer in place, ensuring consistent results, and they are also easy to remove.

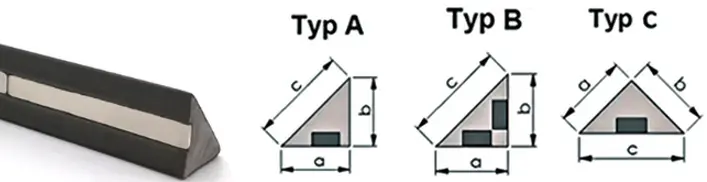

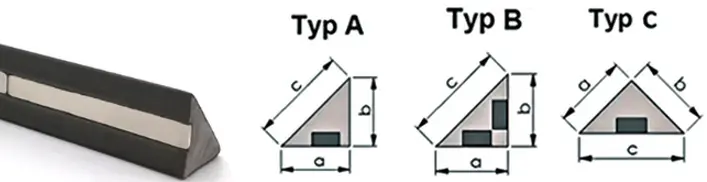

If the magnetic steel chamfer strip will adhere to one steel surface at a time, such as a steel table or steel face plate, select the single-sided magnetization option (Type A or Type C in the chart below). When you are working with two adjacent steel sections, the double-sided magnetization option provides extremely strong corner attachment (Type B in the illustration below).

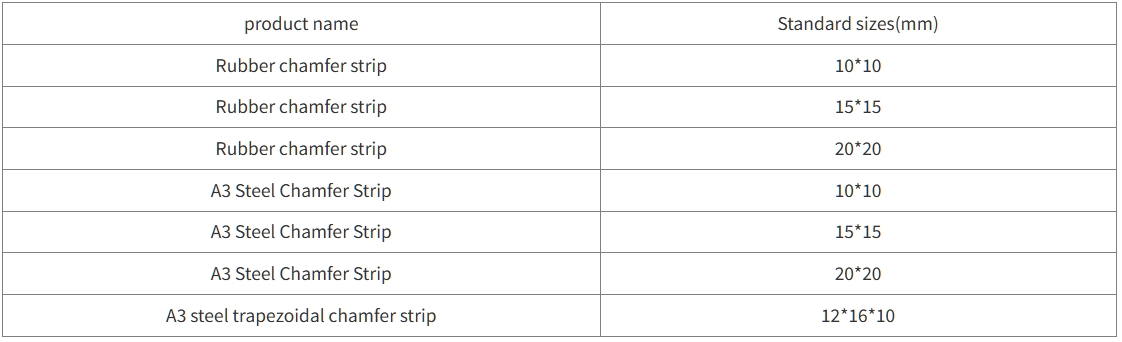

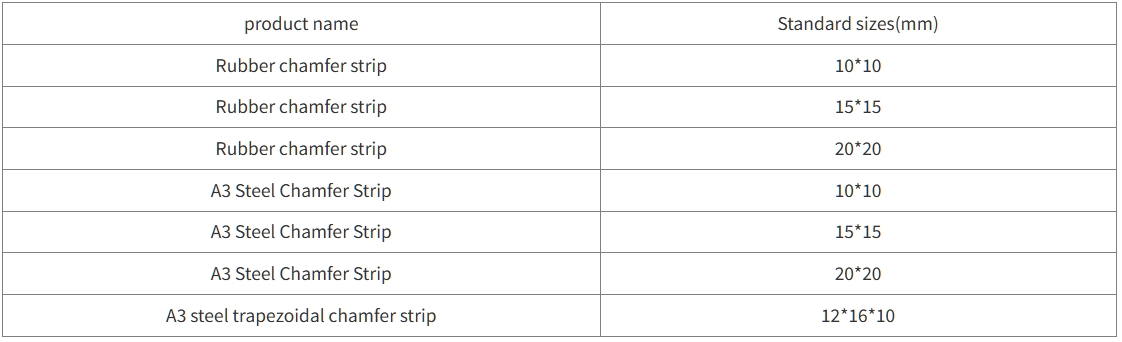

Size chart of magnetic steel chamfer strip

Advantages of QCM triangular magnetic steel chamfer strips:

·Reusability

·High and reliable adhesive force

·Tougher steel material and stronger neodymium magnets for longer life

·Save time

·100% magnetized chamfered strips, strips are completely filled with magnets

Customized Services

We offer flexible customization services to meet the specific needs of our customers. The length of the product can be customized according to your specific requirements, whether it's an extra-long size for large-scale precast concrete projects or a shorter size for small fine components, we can meet them all. Meanwhile, the magnet strength can also be customized, so you can choose the right magnet strength according to the specific requirements of the construction environment, such as the thickness of the concrete structure, vibration during construction, etc., to ensure that the magnet chamfering bar can work stably during the use.

In terms of the customization process, customers only need to submit detailed customization requirements to us, including the required product length, magnet strength and other parameters. Our professional team will contact you within 3 working days after receiving the requirements to confirm the order details and provide accurate production lead time and quotation. The production lead time usually depends on the complexity of the order and the order quantity, and the production is usually completed within [7]-[15] days to ensure that you can get the products you need in time.

Application

Packaging