0102030405

Magnetic shuttering and formwork systems

Hey, let me tell you about magnetic shuttering and formwork systems. They're really cool and super useful, especially in the precast concrete business. Basically, these systems use super - strong magnets to hold the formwork in place. It's a game - changer for making concrete products more efficiently and with more flexibility.

What are Magnetic Shuttering Systems?

Magnetic shuttering systems have neodymium magnets inside a protective steel cover. Their job is to firmly hold the formwork against the casting bed. This means you can set up and take down the molds way faster. And the best part? You don't need to use old - fashioned ways like welding or bolting. Those methods can mess up the surface and make the whole manufacturing process a lot more complicated.

Application

The Big Benefits

• Efficiency: It can cut down the installation time by a whopping 70%!

• Versatility: You can use it for all kinds of precast parts, no matter their shape or size.

• Cost - Effective: You don't need to buy a whole bunch of different standard forms, so you save a ton of money.

• Durability: They're made with high - quality stuff, so they'll last a really long time.

Product Details

These magnetic shuttering systems come in different versions to fit different projects. Here are some common things you should know:

• Material: It's got neodymium magnets in steel cases.

• Holding Power: It can hold anywhere from 450 kg to over 3000 kg, depending on which model you get.

• Temperature Resistance: Usually, it can handle up to 80°C.

- Dimensions:

• Coating options: If you wish, you can request it to be nickel plated or nickel-copper-nickel plated as well as other coatings.

• Customization: QCM can make custom designs just for your project.

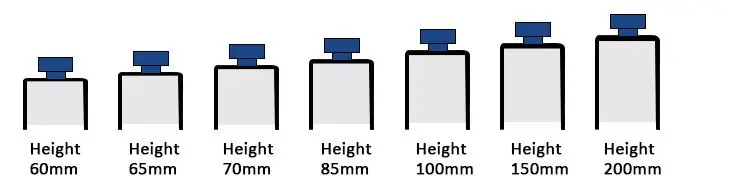

• Adapters: There are lots of different adapters for different height boards and setups. This makes it even more flexible to use.

• Weight: Each magnet can weigh anywhere from 1 kg to a few kilograms, depending on its size and how strong it is.

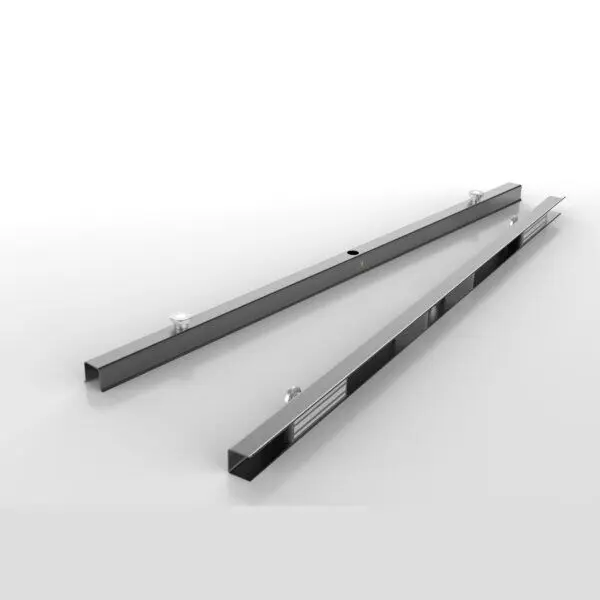

Common Types of Magnetic Shuttering Products

1. Shuttering Magnet Box: This is used to stick templates on steel and wood platforms.

2. U60 Shuttering Magnet: It's made for specific shapes and is great for making complex designs.

3.Magnetic Chamfers: You use this to make grooves in precast concrete panels.

4.Magnet Holders: These are for attaching lifting and fixing anchors.

5.Universal Formwork Systems: It can be used for all sorts of construction jobs, whether it's done by hand or with robots.

These magnetic shuttering and formwork systems don't just make the production process easier. They also make it safer and save on labor costs because setting up the formworks is a breeze. Using magnetic technology in construction is a really big step forward for making precast concrete.