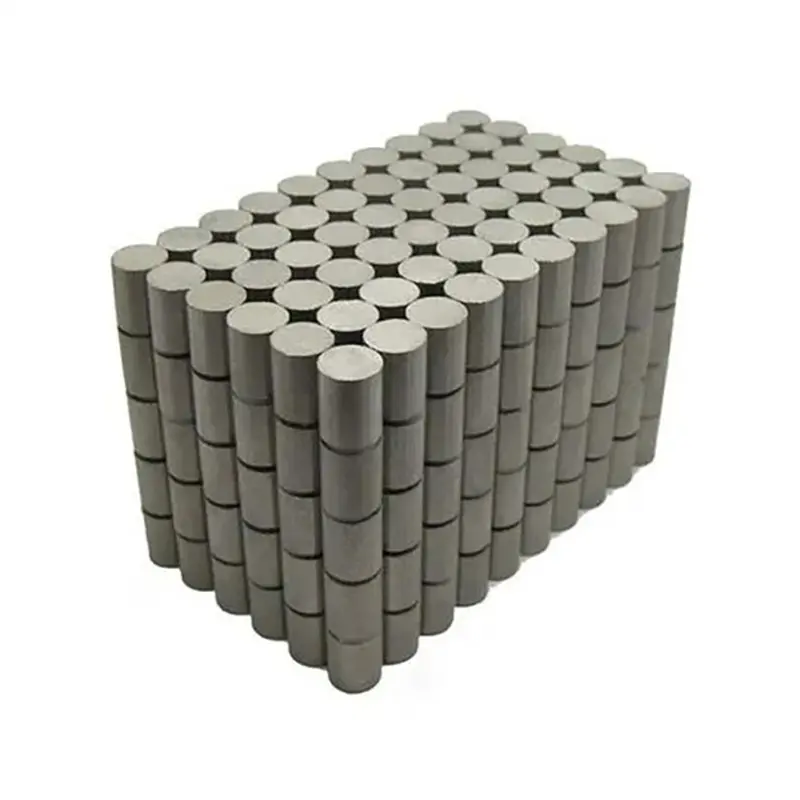

Magnetic Material Rare Earth Permanent Strong Customized High Quality smco magnet

Description

Material Types

SmCo5 (Samarium Cobalt 1:5)

Magnetic Energy Product (BHmax): 18–22 MGOe

Maximum Operating Temperature: 250°C

Sm2Co17 (Samarium Cobalt 2:17)

Magnetic Energy Product (BHmax): 24–32 MGOe

Maximum Operating Temperature: 350°C

Key Features

Superior High-Temperature Performance: Maintains stable magnetic properties at elevated temperatures (250–350°C), outperforming NdFeB magnets in thermal resistance.

High Coercivity: Excellent resistance to demagnetization under mechanical stress or thermal exposure.

Corrosion Resistance: Inherently resistant to oxidation and humidity; optional protective coatings (nickel, epoxy, gold) available for extreme environments.

Customizable Magnetization: Axial, radial, or radial multipole magnetization configurations.

Diverse Shapes: Cylindrical, rectangular, ring, or custom geometries to suit application requirements.

Applications

SmCo magnets are ideal for precision systems requiring stability in harsh conditions:

Automotive & Aerospace: Sensors, actuators, and high-temperature motors.

Medical Devices: MRI equipment, surgical instruments, and implantable devices.

Industrial Equipment: Turbine sensors, robotics, and high-efficiency motors.

Energy & Defense: Radar systems, satellite components, and power generation systems.

Customization Options

Shapes: Standard (cylindrical, rectangular, ring) or custom-designed geometries.

Coatings: Optional nickel, epoxy, or gold plating for enhanced durability in corrosive environments.

Magnetization: Tailored magnetization directions and multipole configurations.

Quality Assurance

ISO 9001-certified manufacturing with full traceability.

Comprehensive testing for magnetic strength, thermal stability, and corrosion resistance.

Technical support for application-specific optimization.

Note: SmCo magnets are specialized solutions for extreme conditions. For cost-sensitive or standard-temperature applications, NdFeB or ferrite magnets may be recommended.