Magnetic Concrete Chamfer Strip

Technical Overview

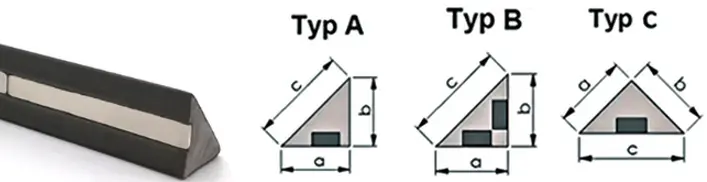

Types & Material Specifications

Type |

Material Composition |

Properties |

Typical Applications |

Urethane Magnetic Strip |

Polyurethane + Neodymium (NdFeB) |

- High flexibility (Shore 60A) - 200+ reuse cycles - Chemical/UV resistant |

Curved edges, architectural finishes |

Steel-Reinforced Strip |

PU + Steel Core + NdFeB |

- Extreme rigidity (Shore 90A) - Industrial abrasion resistance |

Heavy infrastructure (bridges, dams) |

Rubber Magnetic Strip |

Nitrile Rubber + Ferrite Magnets |

- Cost-effective - Moderate adhesion (8 N/cm²) - Limited temperature range |

Small-scale, temporary projects |

PVC Chamfer |

Plastic (non-magnetic) |

- Low-cost disposable - Smooth demolding surface |

Non-magnetic formworks |

Standard Product Specifications

Product Name |

Chamfer Profile |

Dimensions (Width x Length) |

Magnetic Adhesion (N/cm²) |

Urethane |

45° Bevel |

10–200mm x 1–6m |

15–20 |

HeavyDuty |

A3 Steel Trapezoidal (12x16x10mm) A3 Steel Triangle(10x10mm/15x15mm/20x20mm ) |

10–300mm x 1–6m |

25–30 |

Rubber |

10x10mm/15x15mm/20x20mm Chamfer |

10–100mm x 1–3m |

5–8 |

PVC |

10x10mm Chamfer |

10–50mm x 1–2m |

N/A (adhesive-based) |

Core Features

1. Enhanced Durability: Polyurethane strips achieve 5+ years of service life even in abrasive environments.

2. Adaptive Magnet Strength: Grade N42 NdFeB magnets adhere securely to steel, galvanized metal, or mild iron surfaces (15–30 N/cm²).

3. Thermal Stability: Operate reliably between -40°C to 120°C.

4. Rapid Installation: Magnetized strips reduce setup time by 60% compared to screws/clamps.

Benefits & Services

1. Fast Delivery: Stocked standard sizes (e.g., urethane 10–200mm).

2. Customization: Tailor chamfer angles (30°, 45°, 60°), lengths, and magnet strength.

3. Certified Quality: Compliant with ASTM C150 (concrete) and ISO 9001 (magnets).

4. Sustainability: Recyclable materials aligned with GreenCircle® standards.

Applications

· Precast Construction: Align edges of wall panels, beams, and staircases.

· Flooring Systems: Prevent concrete chipping during pouring for polished/terrazzo floors.

· Infrastructure Projects: Ensure edge integrity in tunnels, dams, and industrial flooring.

· Modular Fabrication: Pre-curved profiles for cylindrical columns (5m+ radius).