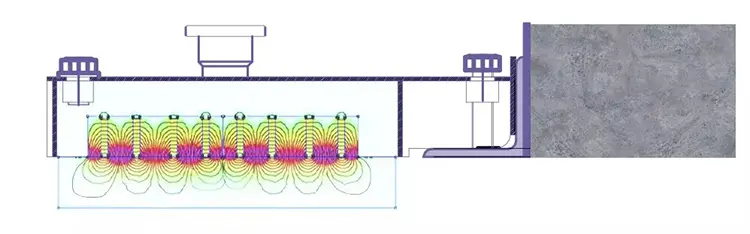

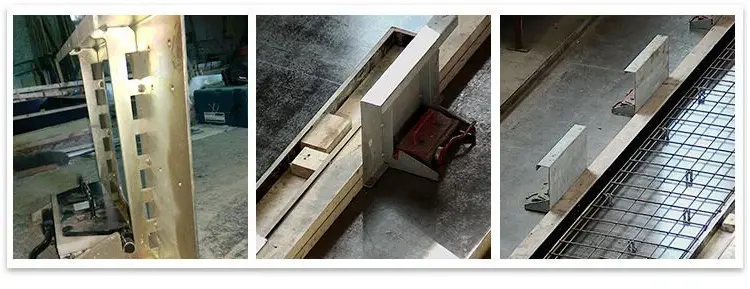

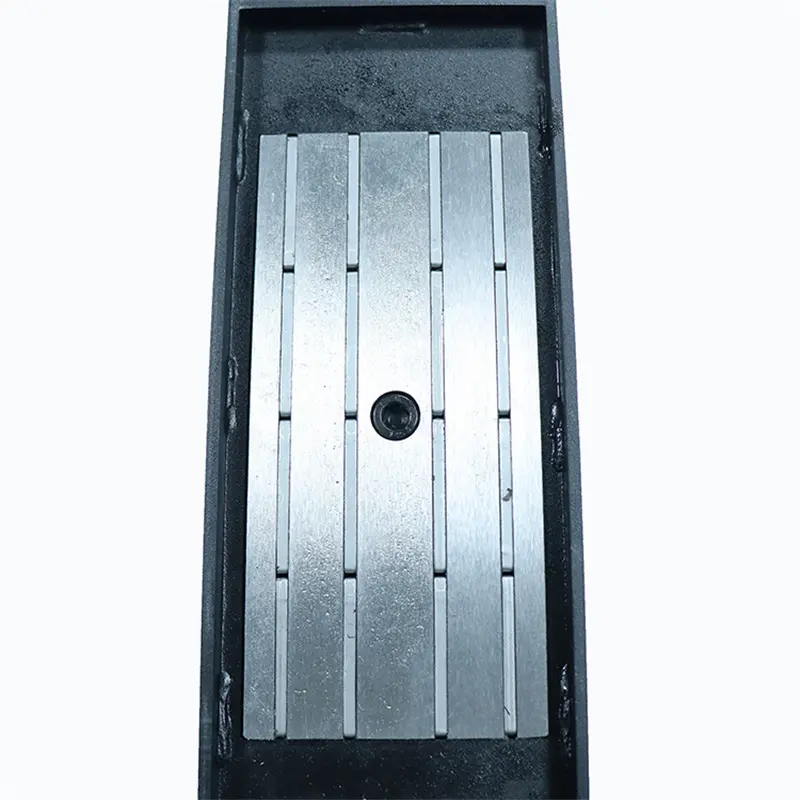

Safe and efficient formwork magnets that have been proven in numerous precast concrete plants. Workers can rotate 3-4 magnet boxes (suction row of 1300 kg) up and place them on the steel table at the same time by hand. By pressing the button on the top of the box, the magnet block in the box is pushed down and seamlessly connected to the steel table. The prefabricated magnets emit enormous magnetic force that can firmly fix the concrete frame. As can be seen from the following picture, this is a precast concrete step magnet. Uniquely designed grooves are used to hold the frame edges.

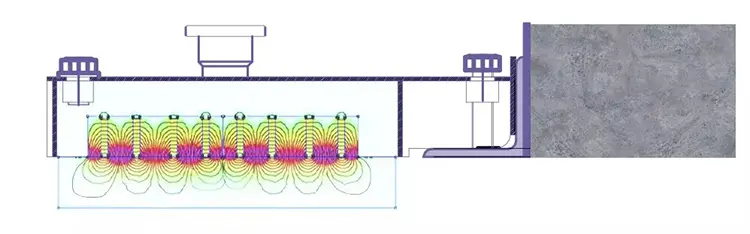

Precast concrete stepping magnet working principle diagram

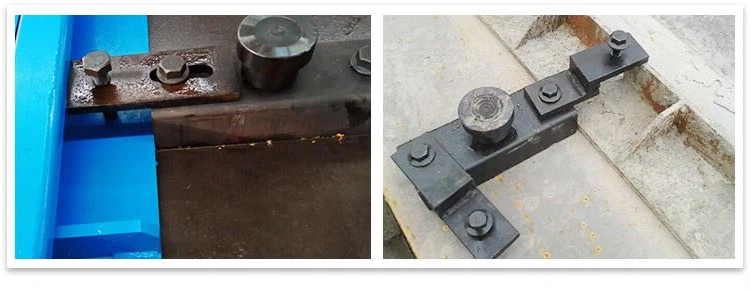

If you choose a product without step magnet, you can lock the adapter with the screws on the box and let the adapter fix the edge of the frame.

Shuttering Magnet Description

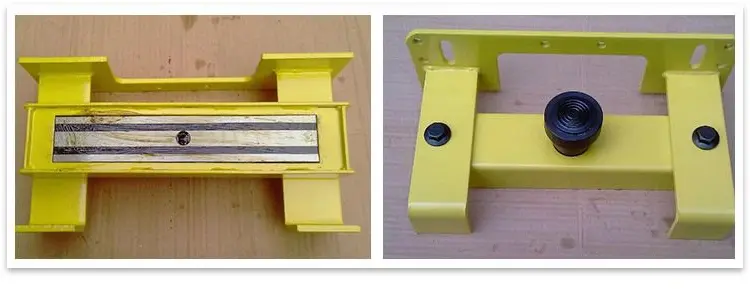

The main force of the new improved products is the 1600kg concrete formwork magnets, which have strong magnetic force, good reusability and durability. Beautiful appearance, carbon steel housing and ferrule provide double protection for fragile magnets. The magnet matrix consists of 16 permanent strong magnets (neodymium magnets), which amplify the power of the active magnets. It is suitable for all concrete frames, including steel or wooden formwork frames. Combined operation with the adapter is more flexible. The grade 12.9 screws used to connect the adapters have high hardness and tensile strength. Its Rockwell hardness (HRC) can be between 39 and 44 and its tensile strength can reach 1220 N/mm2. Thus, the screws ensure an inseparable connection with the adapter and provide a strong hold when producing precast concrete elements. The seamless design of the precast wall fabrication magnet is also a highlight of this product. Product designers strive to minimize gaps to prevent the ingress of small particles such as concrete, fine sand and iron filings during the production process.

Magnet shuttering product specification sheet

|

|

Name

|

1600Kg precast concrete shuttering magnet

|

|

Material

|

Iron+magnet

|

|

Size

|

27*12*6cm

|

|

Net weight

|

6.3kg

|

|

Pull force

|

≥1600kg

|

|

Application to formwork height

|

100-220mm

|

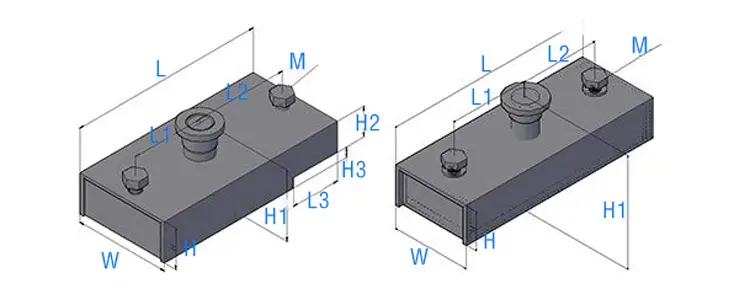

Precast Magnet Detailed Specifications

| Item |

L

mm

|

W

mm

|

H

mm

|

LI

mm

|

L2

mm

|

L3

mm

|

HI

mm

|

H2

mm

|

H3

mm

|

M |

Pull Force

≥kg |

| QCM-450 |

170 |

60 |

40 |

67.5 |

67. 5 |

-- |

73 |

66.5 |

-- |

M12 |

≥450 |

| QCM-600 |

170 |

60 |

40 |

67.5 |

67. 5 |

-- |

73 |

66.5 |

-- |

M12 |

≥600 |

| QCM-600B-Step |

200 |

60 |

40 |

72.5 |

97. 5 |

42 |

73 |

66.5 |

10 |

M12 |

≥600 |

| QCM-800B |

190 |

95 |

43 |

67 |

93 |

50 |

80 |

73.5 |

10 |

M12 |

≥800 |

| QCM-900 |

280 |

60 |

40 |

122 |

122 |

-- |

73 |

66.5 |

-- |

M12 |

≥900 |

| QCM-900B |

195 |

95 |

43 |

67 |

98 |

50 |

80 |

73. 5 |

10 |

M12 |

≥900 |

| QCM-1000B-Step |

200 |

95 |

43 |

67 |

100 |

50 |

80 |

73. 5 |

10 |

M12 |

≥1000 |

| QCM-1350 |

320 |

90 |

60 |

135 |

135 |

-- |

98 |

90 |

-- |

M16 |

≥1350 |

| QCM-1350B-Step |

320 |

90 |

60 |

113 |

161 |

47 |

98 |

90 |

10 |

M16 |

≥1350 |

| QCM-1300 |

210 |

95 |

45 |

80 |

90 |

40 |

73 |

65 |

10 |

M16 |

≥1300 |

| QCM-1600 |

270 |

120 |

60 |

110 |

110 |

-- |

98 |

90 |

-- |

M16 |

≥1600 |

| QCM-1800 |

320 |

120 |

60 |

135 |

135 |

-- |

98 |

90 |

-- |

M16 |

≥1800 |

| QCM-2100 |

320 |

120 |

60 |

135 |

135 |

-- |

98 |

90 |

-- |

M16 |

≥2100 |

| QCM-2400 |

320 |

120 |

60 |

135 |

135 |

-- |

98 |

90 |

-- |

M16 |

≥2400 |

|

QCM-2600

|

320 |

120 |

60 |

135 |

135 |

-- |

98 |

90 |

-- |

M16 |

≥2600

|

How Does the Shuttering Connect and Fix to the Side Formwork?

1. By Pressing Plating

2. Follow the steps on the magnetic box

3. By Clamp

4. By Frame

5. By Wood Clamp

Why choose our precast magnets?

1. Our products are subject to strict quality control starting from the materials used, including grade 12.9 screws, high quality springs and magnets protected by stainless steel housings.

2. We are the origin factory and our products are manufactured to high standards to ensure quality. Besides, our prices are competitive.

3. We have thousands of square meters of production area and large warehouse areas, which enables us to meet the demand for raw material inventory and ensure on-time delivery.

4. We have advanced and complete production facilities and skilled technicians to help the factory run efficiently and improve production efficiency.

5. We have a first-class business service team that can help you solve any problems during the procurement process.

6. We have a strong team of engineers that can meet customers' customized requirements for magnetic roller shutters.

Packing & Shipping