Magnet formwork systems for concrete precast factories

What is Magnet formwork systems ?

The magnetic formwork system is a device that uses a magnetic system built into the steel profile shell to fix it on the casting platform. They have the appearance of long columns and are flexible and quick to install. It comes in many sizes to meet the needs of concrete production of different specifications.

Main Features

The outer shell of the magnetic formwork system is the formwork, but it has a built-in magnetic system to ensure that the side formwork is tightly bonded to the platform, so as to firmly fix the entire system in the desired position. This structure effectively replaces the traditional method of drilling and welding formwork, which not only improves the speed of installing the formwork, but also reduces the risk of damaging the casting platform.

Common specifications of Magnet formwork systems

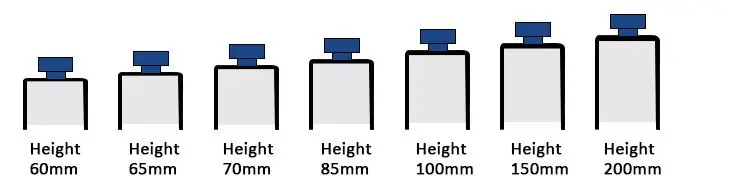

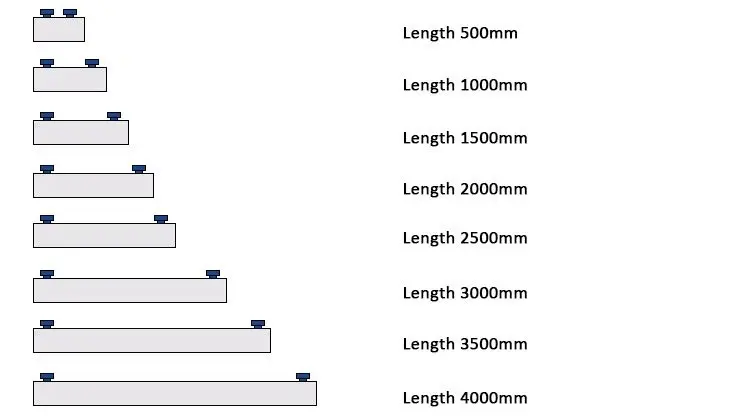

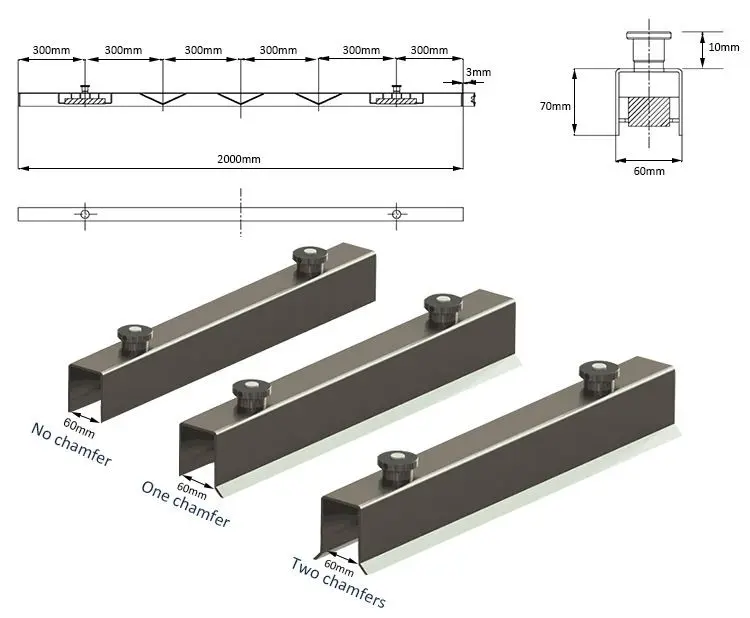

The standard width of magnetic formwork system is 60mm, all sizes and shapes can be customized to suit various precast concrete applications. Standard lengths range from 500mm to 4000mm and heights range from 60 to 200mm.

Height of Magnet Formwork Systems

Length of Magnet formwork systems

Chamfering of Magnet formwork systems

Production equipment of QCM Magnet