0102030405

Magnet Formwork Magnetic Shuttering System

The Magnetic Shuttering System has multiple benefits for the manufacture of precast concrete products.

1. Efficient Mold Change: The Magnetic Shuttering System uses the permanent magnetic force of a lasting magnetic material, encountering no electrical energy consumption, making it very smooth and dependable. This allows for avoiding mold wear and tear from excessive force or poor handling during mold change, thus extending the durability of the mold.

2. Flexible production: No extra stockpiling is needed to satisfy customer orders, meaning increased production flexibility.

3. Safe and reliable: Magnetic Formwork utilizes the permanent magnetic force of permanent magnetic material to work without the need for electrical energy to maintain the working force. Once suction on the mold, no external factors (including human factors) can change or reduce the size of the magnetic force.

4. Reduced downtime: As a key component of quick mold changes, Magnetic Formwork can significantly reduce downtime and increase machine productivity.

Magnetic Shuttering System

Maintenance and repair measures

The maintenance and care of the Magnetic Shuttering System requires special measures to ensure its stability and reliability. The following are the detailed maintenance and repair measures:

1. Professional operation: Maintenance of Magnetic Formwork and control system must be carried out by professional personnel to avoid equipment damage caused by improper operation.

2. Avoid wet hand operation: It is forbidden to touch the button switches and key switches with wet hands in order to avoid electric shock accidents.

3. Clean the working area: the mold changing working area should be kept clean to prevent foreign objects from entering into the equipment or template, which may affect the normal operation of the equipment.

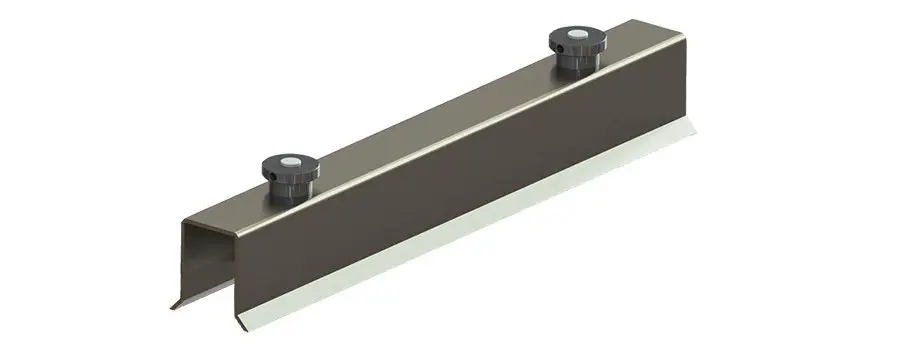

Magnetic Formwork

4. Regular inspection and maintenance: The system should be set up with an effective early warning system to issue timely warning signals for possible abnormalities in the equipment and to remind operators to take corresponding measures. At the same time, regular maintenance and repair of the equipment to ensure the stability and reliability of the equipment.

5. User's manual: In the process of implementing the maintenance and inspection, you must carefully read the user's manual in the product shipment list and operate according to the instructions in the manual.

6. Maintenance of Ambient Temperature Sensitive Devices: For thermal sensitive devices, it is necessary to follow the manufacturer's instructions for maintenance to ensure that they operate properly at the appropriate ambient temperature.

7. Maintenance of oil cup devices: Maintain the correct oil level, use the manufacturer's recommended oil to avoid the formation of slime, and clean and replenish with fresh oil as necessary.

8.Avoid excessive wear: ensure that the magnetic device moves freely and that the non-magnetic gaskets are not excessively worn or damaged.