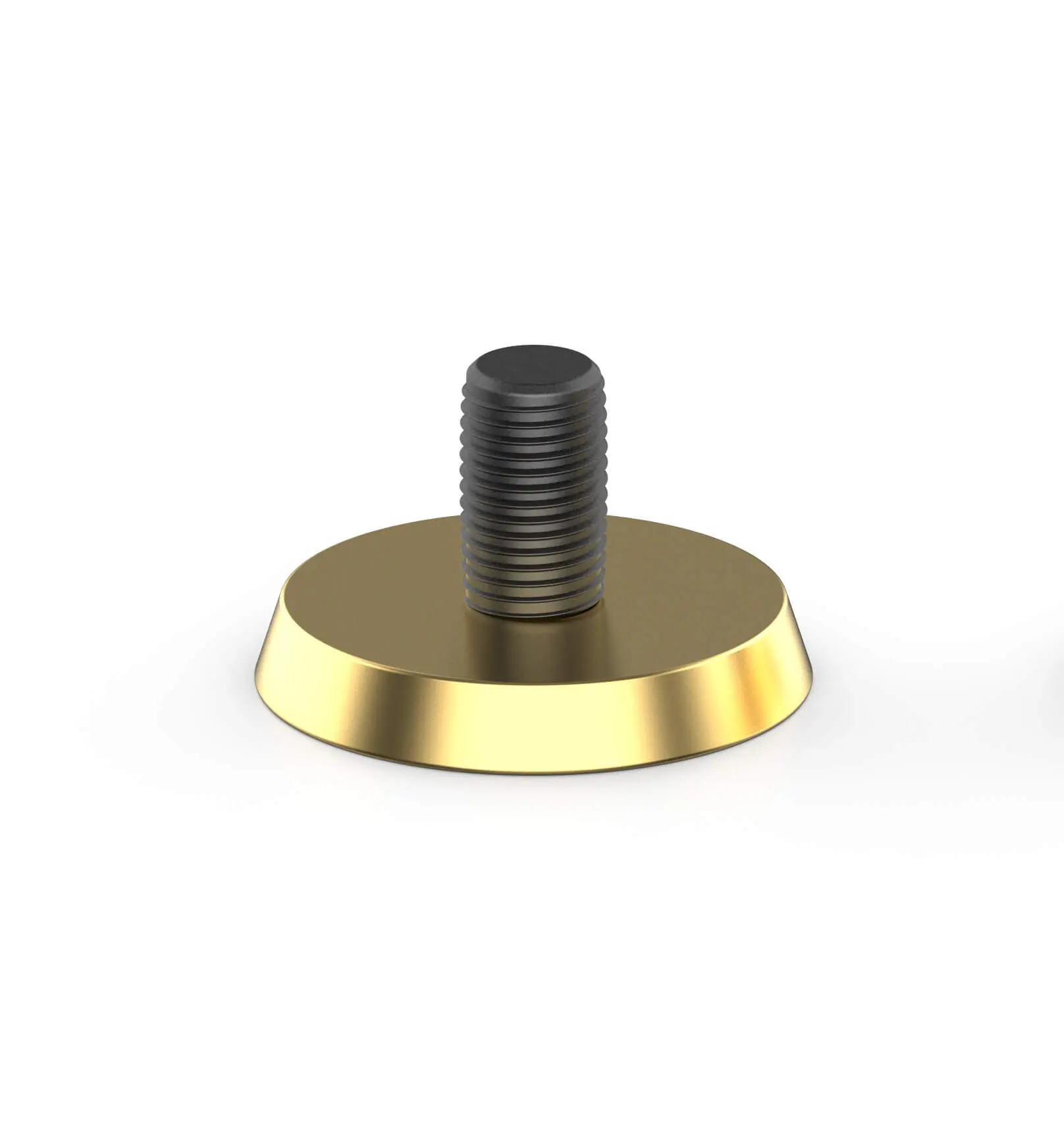

Precast Lifting Socket lifting socket magnets M10

Product Overview

The QCM-D50 Lifting Socket Magnet is a CE-certified industrial tool designed to secure M10 threaded lifting sockets in concrete molds during casting, replacing welded/bolted fastenings. Engineered for 20 kg dynamic lifting (60 kg static holding force), it ensures safety, efficiency, and reusability in precast workflows.

Key Features & Corrections

Magnetic System

-

- 600 N (60 kgf) holding force (tested on ST37 steel, ≥3 cm² contact area)

- 3:1 safety factor (EN 13155-compliant): 20 kg rated dynamic load for concrete elements

- N42 neodymium magnets (Br 1.32 T, 80℃ heat resistance for curing processes)

Threaded Interface

-

- M10×1.5 female thread (depth ≥12 mm),We can also produce M12/M14/M16 thread

- Compatible with ISO 4017/DIN 1480 lifting eyes (Anti-loosening torque ≥ 15 N・m)

Durable Design

-

- IP67-sealed steel housing (Epoxy resin potting) – 100% waterproof/cement-proof

- 500-cycle durability tested (ASTM B656: retention ≥90% force)

Formwork Compatibility

-

- Steel/Aluminum forms (direct magnetic adhesion)

- Wooden forms: Requires pre-embedded steel plates (sold separately)

Applications

- Precast Elements: Panels (≤200 kg), beams, columns, and utility tunnels

- Casting Stages: Secure sockets during concrete pouring, vibration, and curing

- Industries: Construction, infrastructure, and precast manufacturing

Advantages

|

After optimization |

Industry Value |

|

1-operator setup (5min vs 20min welding) |

400% faster installation |

|

500+ cycles (field-tested) |

Reduce cost per use by 80% |

|

CE marked + EN 13155 compliance |

Comply with EU/international project bidding requirements |

Technical Specifications

|

parameter |

Value / Description |

Standard basis |

|

model |

QCM-D50 |

- |

|

Rated dynamic load |

20 kg (60 kg static holding force) |

EN 13155:2014 |

|

Thread specification |

M10×1.5 internal thread (depth 12mm) |

ISO 724 |

|

Magnet Grade |

NdFeB N42 |

ASTM A36 |

|

Protection level |

IP67 (cement/water resistant) |

IEC 60529 |

|

Applicable temperature |

-20℃ ~ +80℃ (Compatible with concrete curing) |

Prefabricated component industry standards |

Usage Notes

- Installation: Align magnet with formwork hole, screw in socket until flush.

- Inspection: Monthly check for magnetism (≥90% force retention via tester).

Why QCM-D50?

• Products with marked safety factors – avoid overload risks

• Patented sealing design – industry exclusive 5-year anti-corrosion warranty

• Suitable for mainstream lifting rings worldwide – compatible with Hilti HVA 10, Fischer FSB 10