0102030405

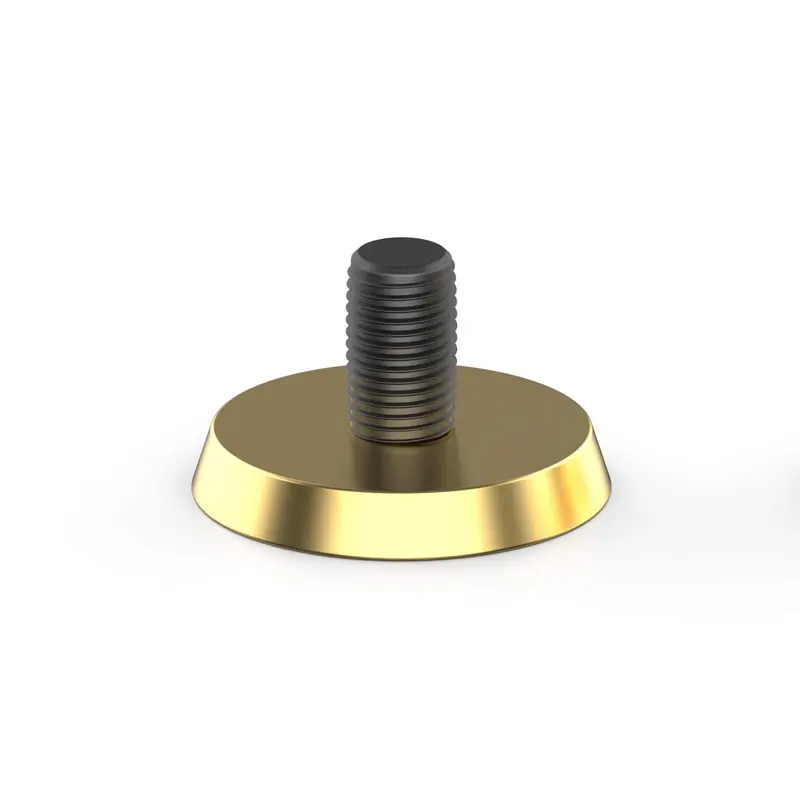

Insert Magnet Of Precast Concrete

Insert Magnet Of Precast Concrete is a magnetic tool used in the production of precast concrete to hold concrete inserts in place by creating a free space in the work piece. These magnets are Constructed with NdFeB rare-earth magnets and corrosion-resistant steel housings, with different sizes having different strengths. According to customer's demand, our company produces multi-specification, multi-style and multi-absorption magnetic holders to connect and fix various kinds of pre-cast concrete inserts, and also equipped with M10, M12, M14, M16, M18, M20, M24 threaded rods for customer's choice.

Specifically, Insert Magnet has been designed to secure lifting anchors (lifting mounts, anchor slots, recessed formers), various embedded components such as PVC pipes or electrical conduits, etc. to the steel formwork. This facilitates construction assembly and ensures that these components do not slide or shift during the concrete pouring process.Insert Magnet uses neodymium magnets, which exhibit a strong attraction even in limited spaces. Their height and diameter can be customized as needed, and the threaded ends can be replaced or welded. The use of these magnets in magnetic formwork systems greatly simplifies a number of production tasks for producers of concrete structures.

|

||||

|

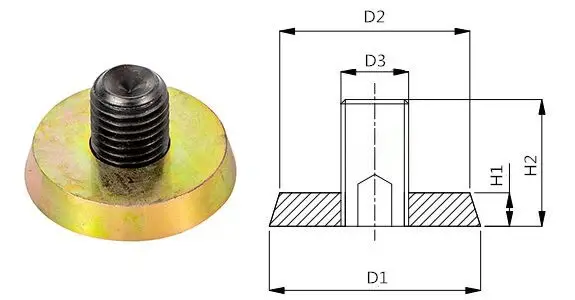

Model |

D1(mm) |

H2(mm) |

Breakaway |

D3 |

|

D50*8 |

50 |

8 |

60 |

M10M12M14M16 |

|

D54*10 |

54 |

10 |

65 |

M18M20M24 |

|

D64*12 |

64 |

12 |

100 |

M16 |

For specific applications, Insert Magnet Of Precast Concrete is mainly used in the following situations:

1. Embedded pipe fixing: When various pipe slots or holes need to be reserved in the precast concrete components, Insert Magnet can be used to fix these pipes conveniently, avoiding misplacing or shifting problems during the pouring process.

2. Formwork fixing: Securing pre-embedded components to steel formwork during concrete pouring, ensuring precise positioning before demolding.

3. Electrical box fixing: In precast concrete equipment, such as electrical boxes and other locations that need to be fixed, Insert Magnet can also be used for fixing to ensure its stability and safety in the process of use.

Aspects of features and advantages:

1. High precision and stability: due to the strong adsorption force of the magnet, it can ensure the close contact between the formwork and the formwork, thus improving the precision and stability of the concrete pouring.

2. Cost-effectiveness and durability: Enhances production efficiency by 30% compared to traditional methods, reducing labor and material costs.

3. Versatility and Flexibility: Different types of magnets can be selected according to different needs, such as magnets for pipe fixing, magnets for formwork fixing, etc., to meet the needs of a variety of construction scenarios.

4. Environmental protection and sustainability: magnetic materials are mostly Made with durable materials for long service life, which meets the requirements of green building and sustainable development.

Insert Magnet Of Precast Concrete plays an important role in the production of precast concrete, which significantly improves the quality and reliability of concrete components by increasing construction accuracy and efficiency.

Application Pictures of Insert Magnets with External Thread:

QCM magnet precast concrete magnets production equipment

QCM magnet shutting magnet box pull force test equipment

Package of Fixing Magnets Insert Magnet