What materials are used in the construction of shuttering magnets?

Shuttering magnets are essential tools in the precast concrete industry, designed to securely hold formwork in place during the pouring of concrete. The construction of these magnets involves several key materials:

Materials Used in Shuttering Magnets

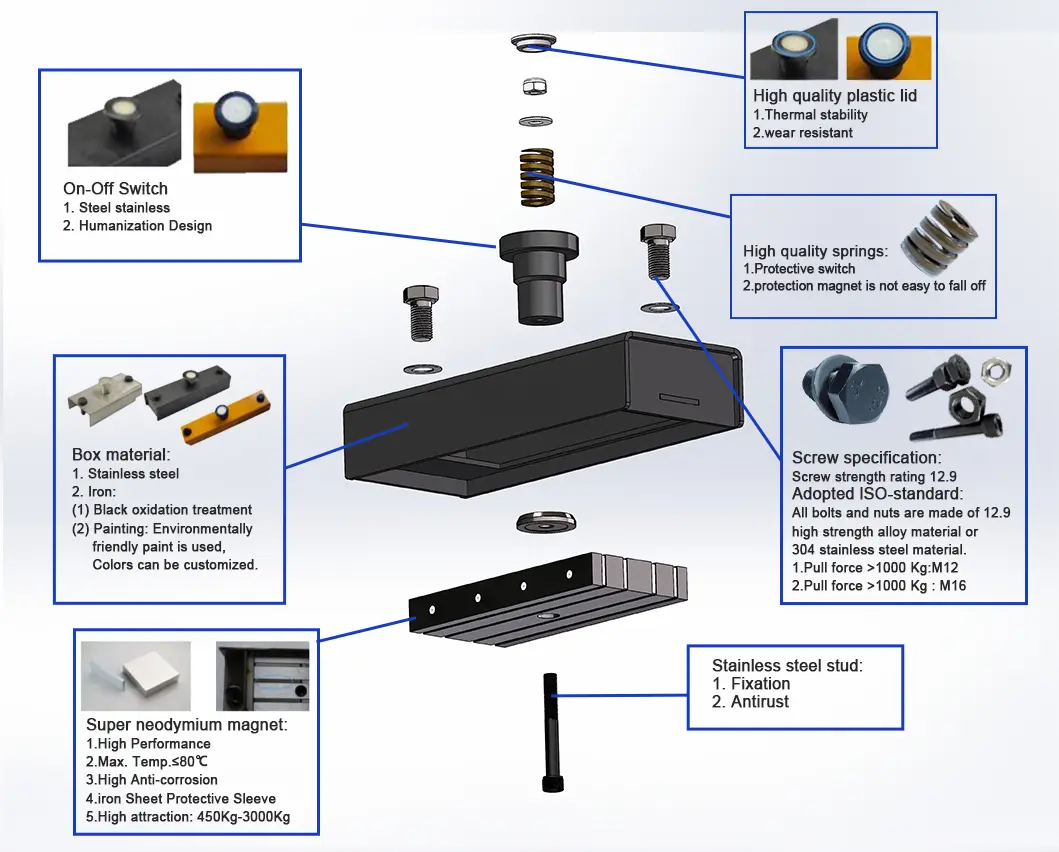

- Neodymium Magnets:

- These are the primary magnetic components used in shuttering magnets due to their strong magnetic properties. Sintered neodymium magnets provide the necessary holding force to secure formwork against the pressure of wet concrete.

- Steel Casing:

- The magnets are encased in a durable steel housing, which serves multiple purposes: it protects the magnets from damage, focuses the magnetic force downward, and provides structural stability. The steel casing is often treated to prevent corrosion and enhance durability.

- Fixing Screws and Control Mechanism:

- Shuttering magnets include fixing screws that allow for secure attachment to various types of formwork. Additionally, they feature an on/off switch mechanism (a button or handle) that enables quick activation or deactivation of the magnetic force, facilitating easy adjustments during setup.

- Plastic or Epoxy Coating:

- Some models incorporate a plastic or epoxy coating on the steel surface to prevent abrasion and damage during use, ensuring longevity and maintaining surface integrity.

These materials work together to create a reliable and efficient tool for securing formwork, significantly improving the speed and safety of concrete pouring operations.