What is the use of Shuttering magnets in construction?

Shuttering magnets are specialized tools used in the construction industry, particularly in the precast concrete sector. They play a crucial role in forming and securing concrete molds during the pouring process. Here’s a detailed overview of their uses and benefits:

Functionality of Shuttering Magnets

Shuttering magnets are designed to hold formwork securely in place, allowing for efficient pouring and setting of concrete. They consist of strong neodymium magnets encased in a durable housing, which can be easily attached to steel surfaces. The primary functions include:

- Formwork Support: Shuttering magnets are used to secure side rails and blocks when pouring concrete, ensuring that the formwork remains stable under the weight and pressure of the wet concrete.

- Quick Setup: They facilitate rapid installation and removal of formwork, significantly reducing setup time compared to traditional methods that often require welding or bolting.

- Versatility: These magnets can be adapted for various types of formwork, including wood, aluminum, and steel, making them suitable for different construction needs.

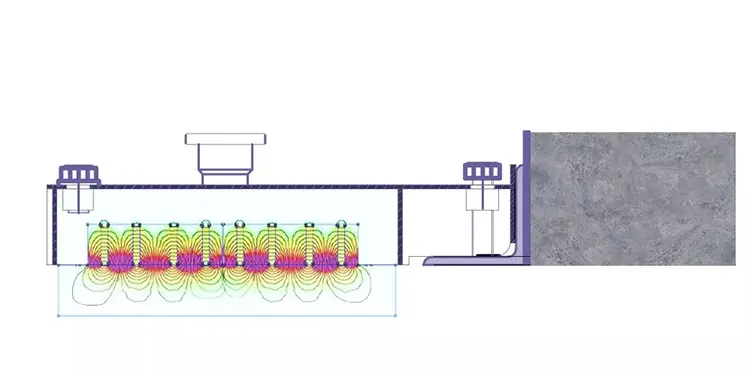

Working principle diagram of precast concrete magnet

Advantages of Using Shuttering Magnets

The adoption of shuttering magnets in construction offers several advantages:

- Time Efficiency: The quick installation process allows for faster project completion. Shuttering magnets can save up to 70% in shuttering time, which accelerates overall production speed.

- Cost Reduction

Shuttering magnets offer significant cost savings compared to traditional formwork systems in several key areas:

Material Costs

- Shuttering magnets are reusable, with some systems lasting up to 200-300 uses. This allows the initial investment to be spread across multiple projects, reducing material costs per project.

- In contrast, traditional formwork systems like timber and plywood are often single-use, resulting in higher material costs per project.

- The lightweight and durable nature of shuttering magnets reduces damage and waste, further lowering material costs.

Labor Costs and Productivity

- Shuttering magnets are simple to use, requiring minimal training and expertise. This allows for more effective workforce allocation and faster project completion.

- Traditional formwork systems are often cumbersome and time-consuming, requiring a larger workforce and leading to higher labor costs.

- Shuttering magnets enhance safety by providing a secure working environment, reducing the risk of accidents and injuries that can drive up costs.

Using shuttering magnets in the construction industry can reduce costs

Equipment and Tooling Expenses

- Shuttering magnets eliminate the need for expensive, bulky equipment required by traditional formwork systems. This reduces capital expenditures and storage costs.

- Shuttering magnets require minimal tooling, saving on purchase and maintenance expenses compared to the specialized tools needed for traditional formwork.

Other Cost Savings

- Shuttering magnets provide an airtight seal, allowing for precise concrete placement and optimal compaction. This improves quality and reduces rework costs.

- Shuttering magnets are easy to install, with no special tools or welding required. This reduces installation time and labor costs.

- Using shuttering magnets can save up to 70% in shuttering time compared to traditional methods, accelerating production and reducing overall costs.

- Improved Safety: The use of magnets reduces trip hazards associated with clamps and other tools, enhancing safety on construction sites.

- Enhanced Quality Control: The strong hold provided by shuttering magnets ensures that formwork remains aligned during the pouring process, leading to higher quality concrete structures with precise dimensions.

- Reusability: Shuttering magnets can be reused across multiple projects, further lowering costs over time and contributing to sustainable construction practices.

Applications in Construction

Shuttering magnets are widely used in various applications within the construction industry:

- Precast Concrete Production: They are essential in the manufacturing of precast wall panels and other concrete elements, allowing for efficient production lines that can adapt to different designs and specifications.

- Custom Formwork Solutions: The flexibility of shuttering magnets enables construction companies to create custom shapes and sizes for concrete products without extensive modifications to existing equipment.

- High-Rise Buildings and Infrastructure Projects: In large-scale projects like high-rise buildings and bridges, shuttering magnets help maintain structural integrity during the critical pouring phase.

Application of shuttering magnets

In summary, shuttering magnets represent a significant advancement in construction technology, offering efficiency, cost savings, safety improvements, and enhanced quality in precast concrete applications. Their growing popularity reflects a shift towards more innovative and effective construction methods.