What is the difference between neodymium magnets N35 and N52?

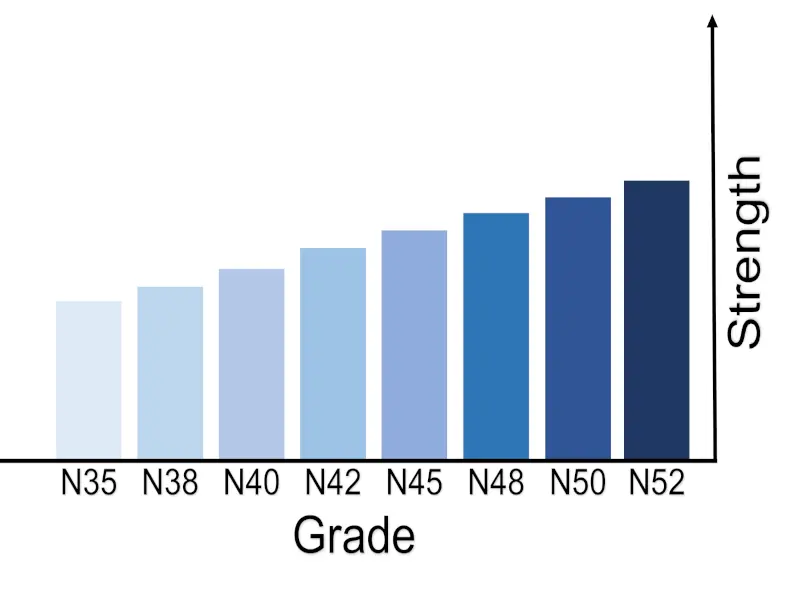

Neodymium magnets are categorized into various grades based on their magnetic strength, which is measured by their Maximum Energy Product (BHmax) in Mega Gauss Oersteds (MGOe). The "N" in magnet grades stands for "Neodymium." The number following the "N" represents the maximum energy product, which is a mathematical product of magnetism and magnet dimensions. The eight standard grades commonly used in commercial applications range from N35 to N52. Here’s a detailed list of these grades:

Standard Grades of Neodymium Magnets

N35: This grade has a BHmax of approximately 35 MGOe, making it one of the lower strength options suitable for general applications.

N38: Slightly stronger than N35, with a BHmax around 38 MGOe, this grade is often used in applications requiring moderate magnetic strength.

N40: With a BHmax of about 40 MGOe, N40 magnets provide a good balance between strength and cost, suitable for various industrial uses.

N42: This grade has a BHmax of approximately 42 MGOe and is one of the most popular grades due to its strong performance and reasonable cost.

N45: Offering a BHmax of around 45 MGOe, N45 magnets are used in applications that demand higher magnetic strength.

N48: These magnets have a BHmax of about 48 MGOe, providing significant power for specialized applications.

N50: With a BHmax around 50 MGOe, N50 magnets are among the stronger options available for demanding applications.

N52: This is the highest standard grade commonly available, with a BHmax of approximately 52 MGOe. N52 magnets are used in high-performance applications where maximum strength is required.

Summary Table

|

Grade |

Maximum Energy Product (MGOe) |

|

N35 |

~35 |

|

N38 |

~38 |

|

N40 |

~40 |

|

N42 |

~42 |

|

N45 |

~45 |

|

N48 |

~48 |

|

N50 |

~50 |

|

N52 |

~52 |

These grades reflect the incremental increase in magnetic strength as the grade number increases. Higher grades like N52 are generally more expensive but provide significantly greater magnetic performance, making them suitable for high-demand applications such as motors, generators, and advanced electronic devices.

Neodymium magnets are categorized by grades that indicate their magnetic strength and properties. The two common grades, N35 and N52, differ significantly in their performance characteristics.

Key Differences Between N35 and N52 Magnets

1.Magnetic Strength and Energy Density

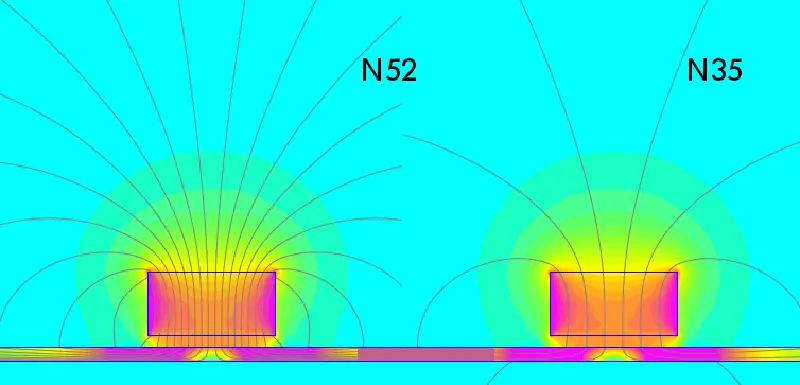

- N35 Magnets: The maximum energy product (BHmax) ranges from 33 to 37 MegaGauss Oersteds (MGOe), which translates to a magnetic flux density (Br) of approximately 11.8 to 12.5 kGs.

- N52 Magnets: These have a higher BHmax of 48 to 52 MGOe, with a Br rating of about 14.3 to 14.8 kGs. This means that N52 magnets can generate a magnetic field that is roughly 40-50% stronger than that of N35 magnets when comparing the same size and shape.

2.Coercivity

- Intrinsic Coercivity (Hci) measures a magnet's ability to resist demagnetization. N35 magnets typically have an Hci of around 10.8 to 11.2 kOe, while N52 magnets exhibit a higher Hci of ≥12 kOe, indicating that N52 magnets are better at maintaining their magnetism under external influences.

3.Temperature Resistance

- N35 Magnets: Generally, they can operate at temperatures up to 80°C (176°F) without significant loss of magnetic properties.

- N52 Magnets: These have a lower maximum operating temperature, typically around 60-70°C (140-158°F), making them more susceptible to heat-induced demagnetization compared to N35 magnets.

4.Cost

- Price Differences: N52 magnets are more expensive due to their superior magnetic properties, often costing about 50% more than N35 magnets for similar specifications.

5.Applications

- N35 Magnets: These are widely used in general applications such as household items, educational kits, and DIY projects where strong but not extreme magnetic force is needed.

- N52 Magnets: Their higher strength makes them suitable for specialized applications including high-performance motors, generators, sensors, and other industrial uses requiring compact yet powerful magnets.

Summary Table

|

Property |

N35 |

N52 |

|

Maximum Energy Product (MGOe) |

33 - 37 |

48 - 52 |

|

Magnetic Flux Density (Br) |

11.8 - 12.5 kGs |

14.3 - 14.8 kGs |

|

Intrinsic Coercivity (Hci) |

~10.8 - 11.2 kOe |

≥12 kOe |

|

Maximum Operating Temperature |

Up to 80°C (176°F) |

Up to 60-70°C (140-158°F) |

|

Typical Applications |

General use |

High-performance applications |

In conclusion, while both N35 and N52 neodymium magnets are effective for various applications, the choice between them largely depends on the specific requirements for strength, temperature tolerance, and budget considerations.