What is Magnetic Shuttering System ?

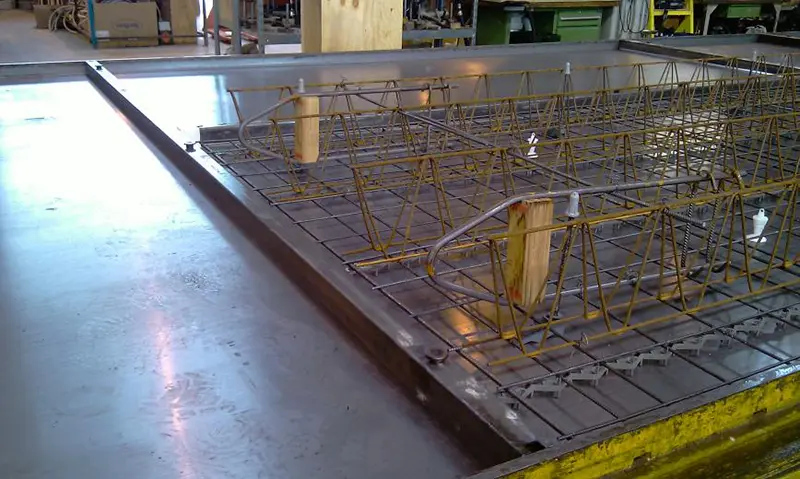

The magnetic formwork consists of a steel mold with an embedded magnetic suction cup system. The mold can be made in various sizes to accommodate different edge forms for concrete elements. Through the tensioning effect of the suction cups, the side molds are firmly adsorbed on the mold table, so that the edges of the components to be molded are fixed. Since the steel molds and the suction cups are a single unit, there is no positional movement, which ensures that the Magnetic fixing and supporting system will not be deformed. At the same time, the simple and quick operation of the suction cup makes the whole work safer and more stable. The suction cups can be pried up and the mold can be easily removed from the table by using the matching pry bar.

Ⅰ.Technical details

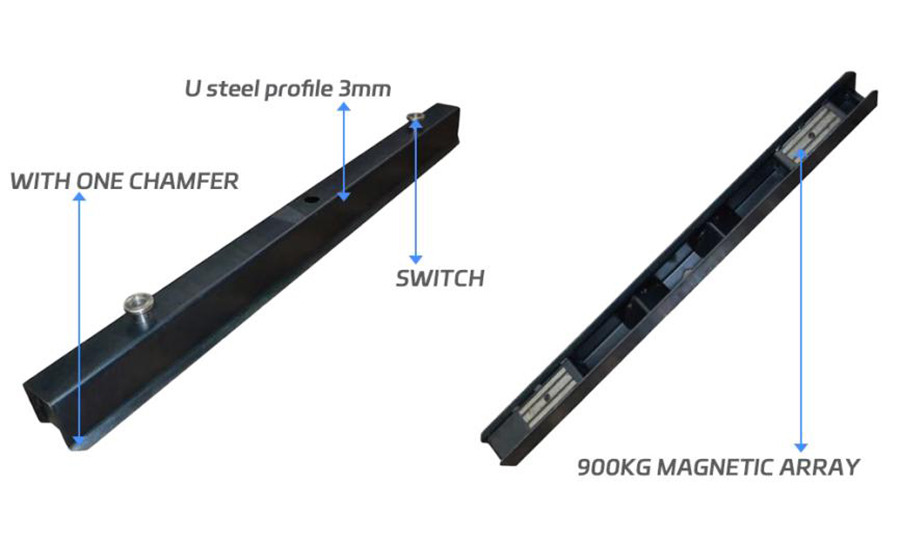

Our Magnetic Shuttering Systems are made with high performance Neodymium Iron Boron magnets and high grade steel.

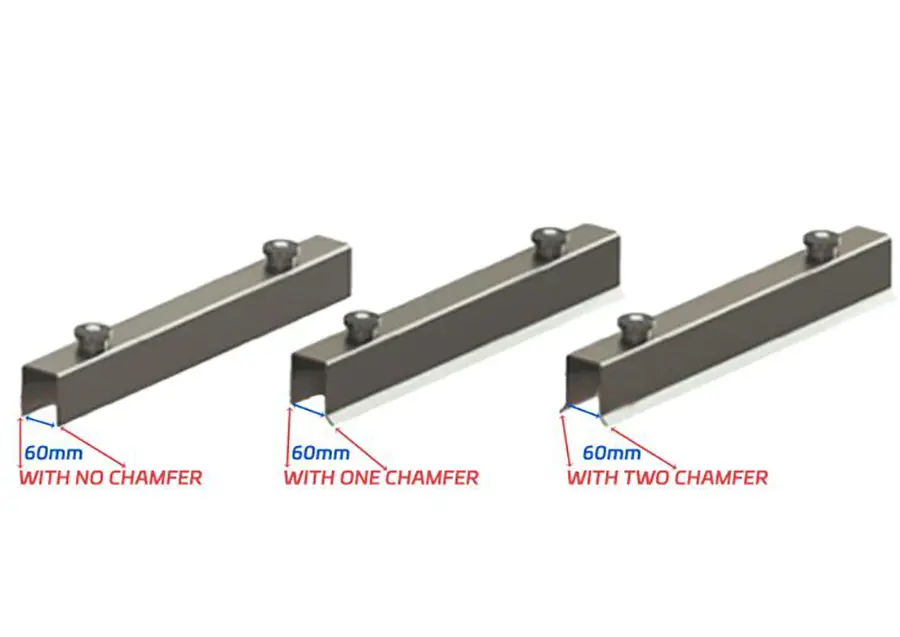

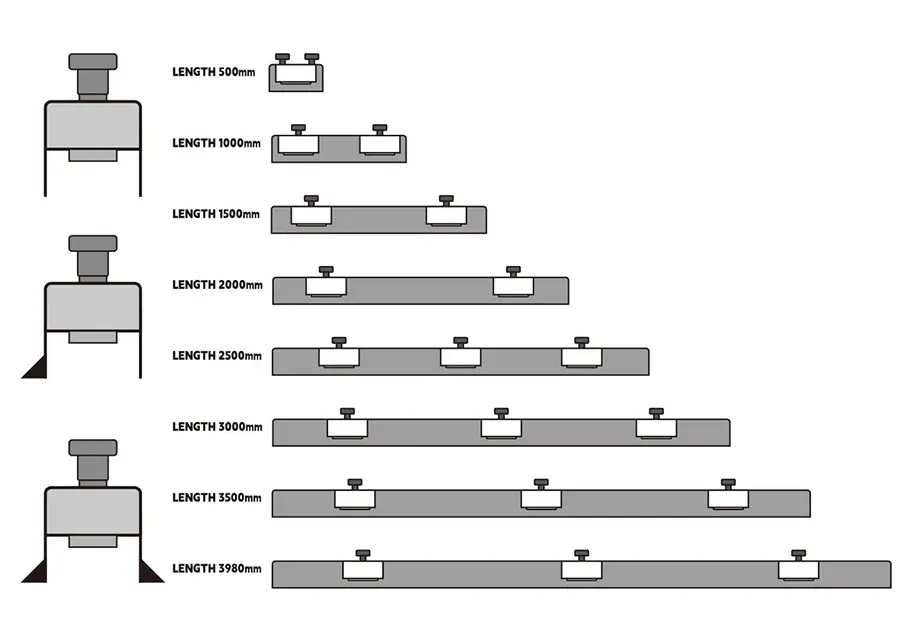

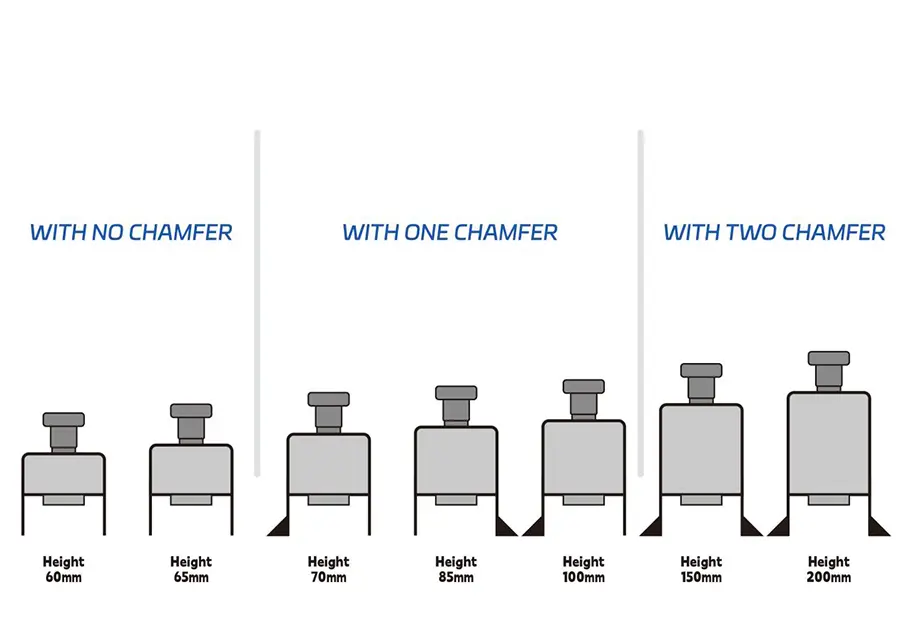

Precast Concrete Formwork Systemis available with one side chamfer, with two sides chamfer or without chamfer, and in lengths of 500mm, 1000mm, 1500mm, 2000mm, 2500mm, 3000mm, 3500mm, 3980mm for your choice.

Standard heights are 60mm, 65mm, 70mm, 85mm, 100mm, 150mm, and 200mm.

Standard width 60mm, steel thickness 3mm, 4mm, 6mm.We are the most powerful MAGNETIC FORMWORK manufacturer in China, we can configure magnetic formwork system of any length and height according to customer's requirements.

Ⅱ.Principle of operation

The formwork for precast concrete is fixed to the edges of the concrete elements by means of a built-in formwork magnet system. The suction cups are magnetically attached to the mold table, ensuring that the edge molds are held in position without deformation. This design allows for quick and easy handling and minimizes damage to the Modular Magnetic Shuttering from concrete debris or other contaminants.

Ⅲ.Product Advantages

Convenient installation and dismantling: no need to use screws, bolts and other connectors for fixing, the installation and dismantling can be realized quickly through magnetic adsorption and matching pry bar, which can effectively save the construction time and labor cost.

Precise positioning: The strong and stable magnetic force can make the side molds fit closely with the mold platform or other structures, and accurately fix them in the designed position, avoiding displacement and deformation during concrete pouring and vibration, and helping to improve the dimensional accuracy and appearance quality of precast concrete components.

Reusable: With high durability and reusability, it is not easy to be affected by concrete residue and other dirt, and can be used repeatedly in several precast concrete component production projects, which reduces the cost of molds.

Protection of molds and mold tables: Compared with traditional mechanical fixing methods, no holes will be drilled or welded in the formwork or mold table, thus no damage will be caused to them and the service life of the formwork and mold table will be prolonged.

Strong environmental adaptability: Since the Shuttering System Magnet is located inside the groove of the steel mold, it is not easy for concrete residue or other dirt to enter, which will not cause damage to the whole Shuttering Magnets System for Pre-cast concrete formwork, and it can maintain stable performance in a relatively harsh construction environment. The system will not damage the entire Shuttering Magnets System for Pre-cast concrete formwork.