What are the benefits of using magnets in the H-profile magnetic shuttering system

The H Profile Magnetic Shuttering System utilizes magnets to enhance the efficiency and effectiveness of concrete formwork in precast construction. Here are the key benefits of using magnets in this system:

Benefits of Using Magnets in the H Profile Magnetic Shuttering System

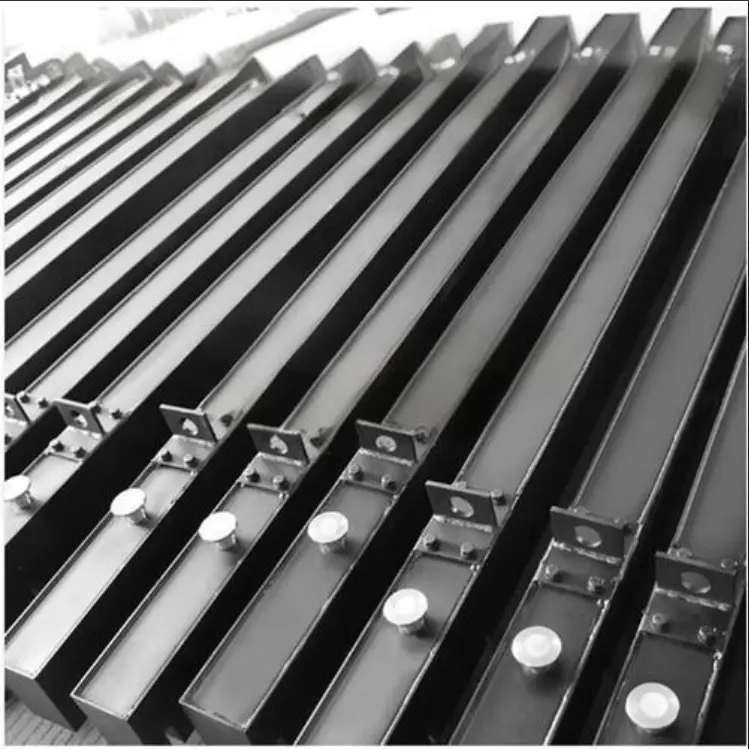

- Rapid Installation and Adjustment: The magnetic activation allows for quick placement and repositioning of the shuttering profiles. This significantly reduces the time required for setup compared to traditional methods that rely on mechanical fasteners like bolts and screws, which can be time-consuming to install and remove.

- Strong Holding Force: The magnets provide a powerful grip that ensures the formwork remains securely in place during the concrete pouring process. This stability is crucial for maintaining precise dimensions and preventing any shifting that could lead to defects in the finished product.

- Reduce labor costs: The magnetic force can be quickly activated by pressing a button and the magnet can be quickly released using a lever, which simplifies the formwork installation process and reduces labor costs. Fewer workers are required to install and adjust the formwork, saving time and labor costs.

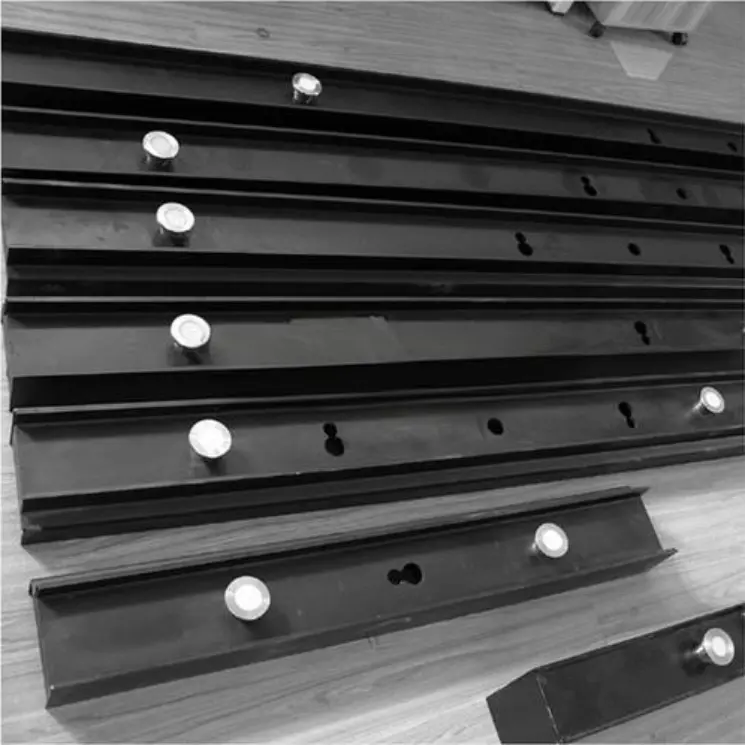

- Versatility: The H-profile Magnetic shuttering system can produce magnetic profiles in various shapes and sizes according to the customer's special requirements for precast elements, so as to form concrete elements in one go, such as chamfers, grooves and other forms. This adaptability makes it suitable for different types of precast elements, thus achieving a wide range of applications.

- Minimized Surface Damage: Since magnets eliminate the need for drilling or welding into formwork surfaces, there is less risk of damaging the mold tables. This preservation of surface integrity extends the life of the formwork and reduces maintenance costs.

- Reusable Components: The magnets are designed for repeated use, making them a cost-effective solution over time. Their durability allows them to withstand harsh working conditions typical in precast environments.

- Improved Safety: The secure attachment provided by magnets minimizes the risk of accidental dislodging during concrete pouring, enhancing overall site safety for workers.

- Customization Options: Magnets can be tailored to meet specific project requirements regarding size, shape, and holding force. This customization ensures that the shuttering system can accommodate various design needs effectively.

In summary, integrating magnets into the H Profile Magnetic Shuttering System offers numerous advantages, including increased efficiency, reduced labor costs, enhanced safety, and improved versatility in precast concrete applications. These benefits contribute to higher quality construction outcomes and greater operational efficiency in precast manufacturing processes.