0102030405

What are the advantages of using shuttering magnets over traditional methods?

2024-12-18

Using shuttering magnets offers several advantages over traditional methods of securing formwork in precast concrete production. Here are the key benefits:

Advantages of Shuttering Magnets

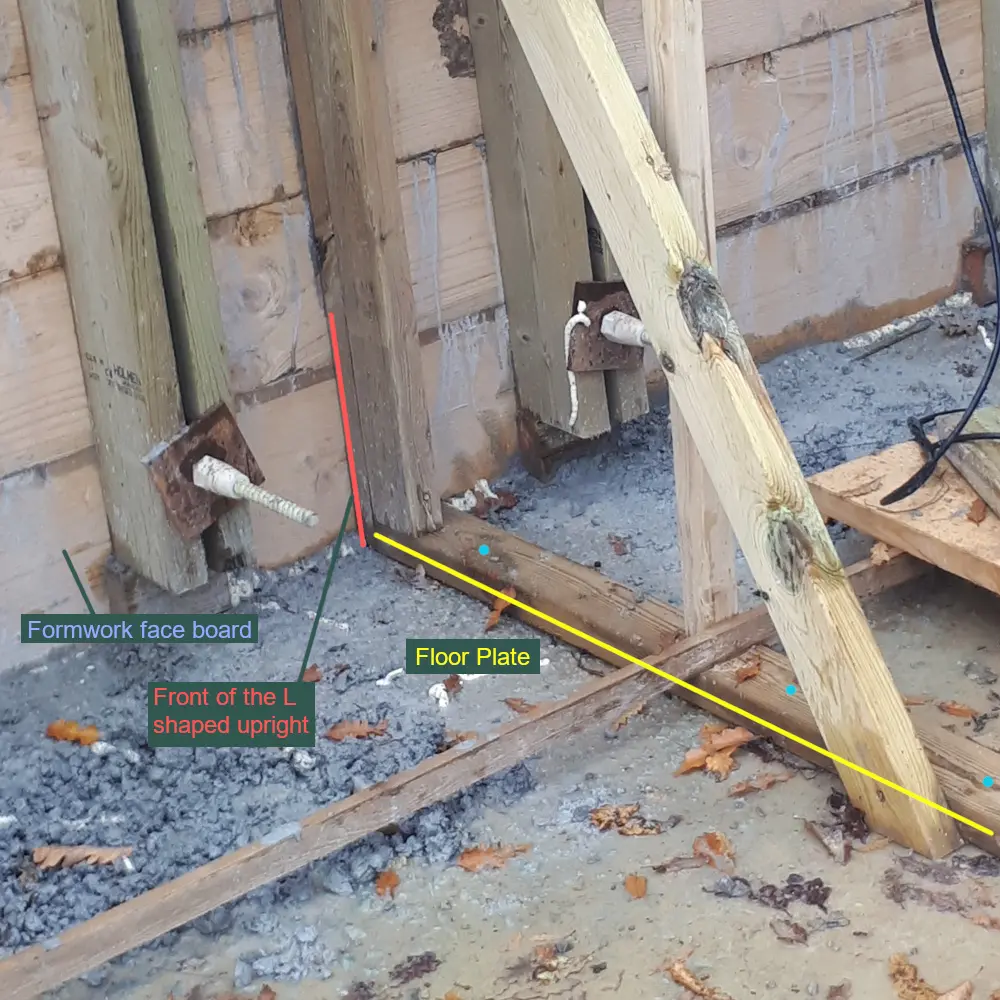

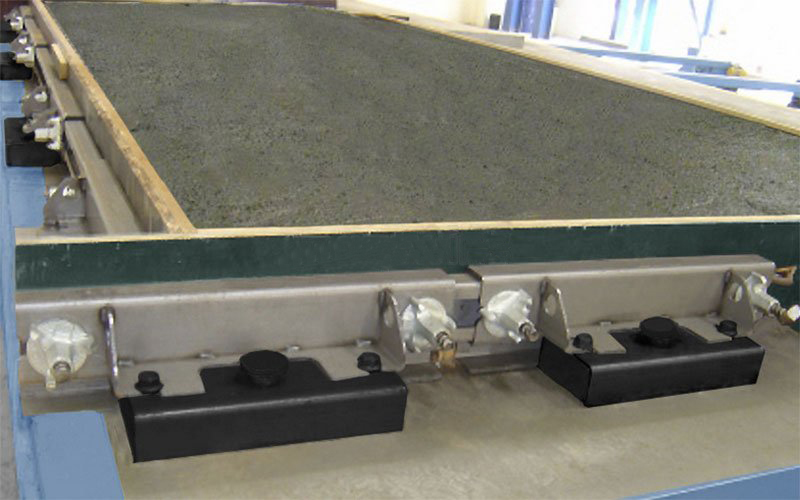

- Speed and Efficiency: Traditional methods such as using nails, screws, or clamps to fix formwork can be time - consuming. For example, when using nails, workers need to precisely position and hammer each nail into the correct place. In contrast, shuttering magnets can be simply placed onto the metal surface of the formwork support structure. Workers can quickly attach and detach them, which significantly speeds up the installation process of the formwork. This is especially beneficial in large - scale construction projects where time is of the essence.Shuttering magnets can reduce setup time by up to 70% compared to traditional methods, allowing for faster placement and demoulding of formwork. This efficiency translates into shorter production cycles and increased output.

- No Damage to Equipment: When using traditional fixing methods like nails or screws, they create holes in the formwork. These holes can weaken the formwork structure and may lead to leakage of concrete during the pouring process. Shuttering magnets, on the other hand, rely on magnetic force to hold the formwork in place. There is no need to penetrate the formwork material, shuttering magnets operate without these invasive techniques,so the formwork can be reused more easily and is less likely to have issues related to damage - induced weakening. This helps maintain the integrity and longevity of the equipment.

- Cost Reduction: By minimizing labor costs associated with manual fastening methods, shuttering magnets provide a cost-effective solution. Their ability to be reused multiple times further enhances long-term savings on materials and labor.

- Versatility: Shuttering magnets are compatible with various types of formwork materials, including wood, plastic, and steel. This adaptability allows them to be used in different manufacturing scenarios, accommodating various shapes and sizes of precast products.

- Improved Stability and Safety: The strong magnetic force ensures that the formwork remains securely in place during the pouring of concrete, reducing the risk of shifting or accidents. This stability contributes to higher quality concrete structures with precise dimensions.Traditional methods that involve the use of sharp tools like hammers for nailing or drills for screwing pose a certain safety risk to workers. There is a possibility of hand - eye injuries due to flying debris or accidental slips of the tools. Shuttering magnets eliminate the need for such potentially dangerous tools during the installation process of the formwork, thus improving the safety of the construction site.

- High Precision in Formwork Placement:Shuttering magnets allow for more precise positioning of the formwork. Since they can be easily adjusted and moved until the desired position is achieved, it is easier to ensure that the formwork is perfectly aligned and level. This precision helps in producing high - quality concrete structures with accurate dimensions and smooth surfaces.

- Ease of Use: The switchable feature of shuttering magnets allows for quick activation and deactivation, making it easy for workers to reposition formwork as needed without additional tools. This user-friendly design enhances overall operational efficiency.

- Environmental Benefits: By eliminating the need for additional materials like bolts or adhesives, shuttering magnets contribute to reduced waste and promote more sustainable construction practices.

In summary, shuttering magnets present a modern solution that enhances efficiency, reduces costs, and improves safety in precast concrete production compared to traditional fastening methods. Their ease of use and versatility make them an increasingly popular choice in the construction industry.