Understanding Bevel vs. Chamfer in Precast Concrete: What Contractors Need to Know

In the world of precast concrete, even the smallest design details can have a big impact on performance, safety, and efficiency. Among these details, edge treatments like bevels and chamfers play a critical role in how concrete components behave during installation and over their lifespan. While these terms are often used interchangeably, they serve distinct purposes. Let’s break down their differences, applications, and why products like magnetic steel chamfers are revolutionizing the industry.

1. What’s a Bevel? (Hint: It’s All About Angles)

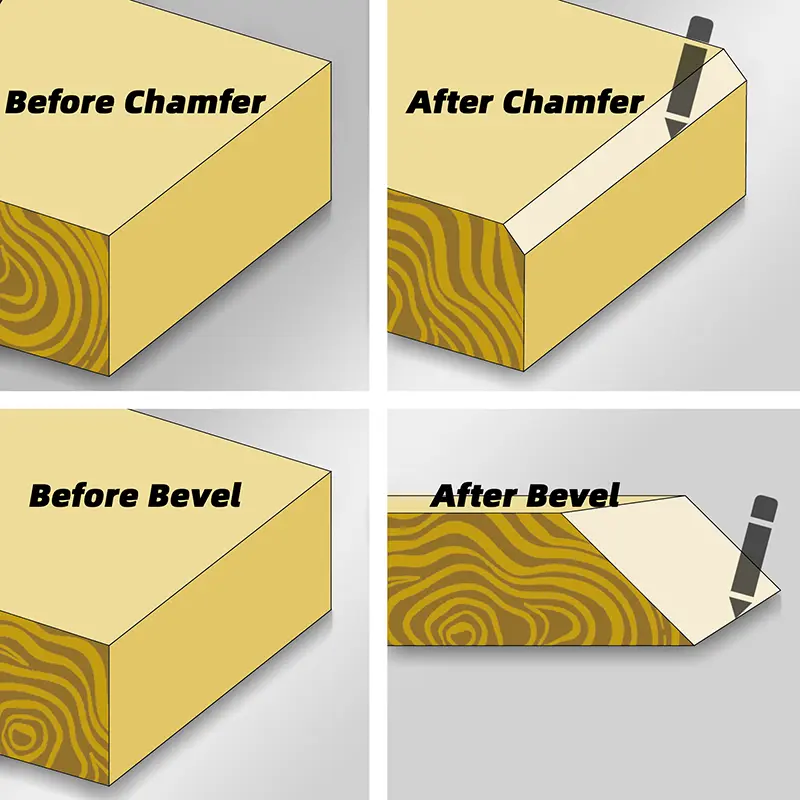

A bevel is an inclined edge cut into a concrete component, typically at an angle greater than 45 degrees relative to the face of the material. Think of it as a “softened” edge that transitions gradually.

Why use a bevel in precast concrete?

- Durability: Reduces chipping during handling or transport.

- Aesthetics: Creates a smooth, finished appearance for visible edges.

- Safety: Eliminates sharp corners, minimizing injury risks on-site.

A classic example is the edge of a precast stair tread. A bevel here prevents cracks from forming at stress points while making the tread safer for foot traffic.

2. What’s a Chamfer? (The Structural Workhorse)

A chamfer is a flat, angled cut—usually at 45 degrees—that removes a sharp 90-degree corner. Unlike a bevel, a chamfer creates a small, flat surface between two adjoining faces.

Why chamfers matter in precast concrete:

- Mold Release: Chamfers help concrete separate cleanly from molds, reducing surface defects.

- Alignment: Simplifies assembly by creating “guide” edges for adjacent components.

- Load Distribution: Redirects stress away from vulnerable corners, enhancing structural integrity.

Chamfers are essential in load-bearing elements like beams or columns, where corner stresses can lead to premature failure.

3. Bevel vs. Chamfer: Key Differences at a Glance

|

Feature |

Bevel |

Chamfer |

|

Angle |

>45 degrees |

Typically 45 degrees |

|

Edge Shape |

Curved or sloping transition |

Flat, linear cut |

|

Primary Use Case |

Aesthetic finishing, safety |

Structural performance, mold use |

|

Stress Handling |

Reduces localized wear |

Distributes load evenly |

4. Magnetic Steel Chamfers: A Game-Changer for Precast

While traditional chamfers are cut directly into concrete, innovations like magnetic steel chamfers are transforming how edges are reinforced. These products consist of steel strips with a chamfered edge and built-in magnets, designed to attach to formwork before pouring.

Benefits of magnetic steel chamfers:

- Speed: Instantly creates precise chamfers without manual cutting.

- Reusability: Strips can be reused across multiple pours, cutting material costs.

- Consistency: Ensures uniform chamfer dimensions, critical for tight-tolerance projects.

- Corrosion Resistance: High-quality coatings protect against rust in harsh environments.

For example, in a precast parking garage project, magnetic steel chamfers allowed crews to achieve flawless beam edges while shaving 20% off formwork setup time.

5. Choosing Between Bevels and Chamfers

Your choice depends on the project’s priorities:

Use a bevel if:

- The component is visible (e.g., architectural panels).

- Safety for handlers or end-users is a top concern.

- You need to minimize edge wear during transport.

Use a chamfer (or magnetic steel chamfer) if:

- The part is structural (e.g., bridge girders).

- Precision alignment with other components is required.

- You’re optimizing for mold reuse and production speed.

6. Pro Tips for Contractors

- Mix and Match: Combine chamfers on load-bearing edges with bevels on exposed surfaces.

- Test Early: Use mock-ups to evaluate edge treatments under real-world conditions.

- Invest in Tech: Magnetic steel chamfers pay for themselves in large-scale or repetitive jobs.

Final Thoughts

In precast concrete, there’s no such thing as a “minor” detail. Bevels and chamfers might seem like subtle design choices, but they directly impact durability, safety, and project timelines. As the industry shifts toward smarter solutions like magnetic steel chamfers, contractors who master these nuances will stay ahead of the curve—literally and figuratively.

By understanding the “why” behind each edge treatment, you’ll make informed decisions that save money, reduce rework, and keep your projects bulletproof.

Need help selecting the right edge solution for your next project? Contact our team to explore how magnetic steel chamfers can elevate your precast workflow.