How to Install Precast Concrete Steps: A Step-by-Step Guide for Professionals

Precast concrete steps are a durable, cost-effective solution for residential and commercial properties, offering long-term performance with minimal maintenance. For contractors and precast manufacturers, ensuring proper installation is critical to maintaining structural integrity and client satisfaction. As a leader in magnetic formwork systems and precast concrete magnets, QCM understands the importance of precision in every stage of production and installation. This guide combines industry best practices with insights on how advanced tools like magnetic formwork can elevate your workflow.

Why Precast Concrete Steps?

Precast concrete steps are manufactured in controlled environments, ensuring consistent quality and faster on-site installation compared to cast-in-place alternatives. Their benefits include:

- Durability: Resistant to weathering, heavy loads, and corrosion.

- Cost Efficiency: Reduced labor and faster project timelines.

- Design Flexibility: Customizable finishes, textures, and dimensions.

For precast manufacturers, achieving these advantages starts with high-quality formwork. QCM’s magnetic formwork systems ensure molds stay securely aligned during concrete pouring, minimizing defects and rework.

Step 1: Pre-Installation Preparation

Site Assessment

• Evaluate the Foundation: Ensure the ground is level and compacted. For soft soils, add a gravel base (4–6 inches) to prevent settling.

• Measure Dimensions: Confirm step dimensions match the precast units. Use laser levels for accuracy.

Material Handling

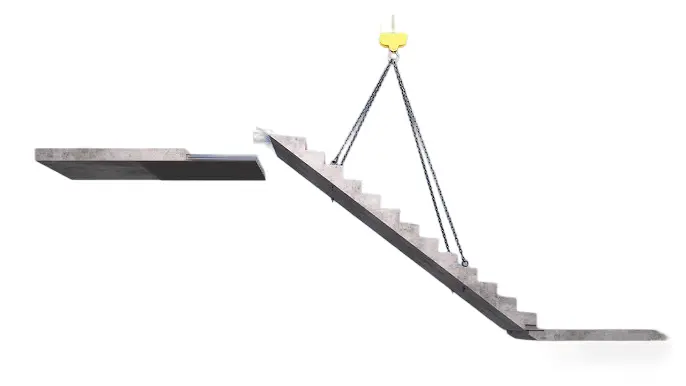

- Transport Safely: Use nylon slings or forklifts to avoid damaging edges during unloading.

- Inspect Components: Check for cracks or misalignments. QCM's magnetic formwork reduces such defects by holding the mold in place during the pouring process.

Step 2: Installing Precast Concrete Steps

Positioning the Steps

- Lay Bedding Material: Spread a 1–2 inch layer of mortar or sand mix to create a stable base.

- Place the Steps: Use a crane or backhoe to lower the steps into position. Align the first step with the foundation, ensuring proper slope for drainage.

Alignment and Leveling

- Adjust with Shims: Insert non-corrosive shims beneath the steps to achieve level placement.

- Verify Alignment: Use a spirit level and measuring tape to confirm horizontal and vertical alignment.

Securing Joints

- Apply Sealant: Use a waterproof concrete adhesive or mortar to bond adjacent steps. For seamless joints, ensure formwork during casting leaves clean edges—QCM’s magnetic systems prevent mold shifts, reducing post-installation adjustments.

Backfilling and Compaction

• Fill Gaps: Backfill around the steps with gravel or soil, compacting in 6-inch layers to avoid voids.

• Final Check: Re-inspect alignment after backfilling.

Step 3: Enhancing Safety and Aesthetics

- Add Railings: Install iron or aluminum railings for compliance with safety codes.

- Apply Anti-Slip Coatings: Opt for exposed aggregate or textured finishes during casting to improve traction.

How QCM’s Magnetic Formwork Elevates Precast Production

For manufacturers, the quality of precast steps begins long before installation. QCM’s magnetic formwork systems address common challenges:

- Precision Alignment: Magnets lock molds in place, eliminating gaps and misalignmentsthat cause leaks or uneven surfaces.

- Faster Demolding: Reduce downtime with quick-release magnetic locks.

- Cost Savings: Minimize material waste and rework by ensuring consistent mold integrity.

Common Installation Challenges (and Solutions)

1.Uneven Settling:

▫ Cause: Poor compaction or unstable soil.

▫ Fix: Use a reinforced gravel base and compact layers thoroughly.

2.Joint Leaks:

▫ Cause: Improper sealant application or misaligned steps.

▫ Prevention: Use QCM’s formwork to cast steps with tight tolerances.

Conclusion

Installing precast concrete steps requires meticulous planning, precise execution, and high-quality materials. For precast manufacturers, investing in advanced tools like magnetic formwork not only streamlines production but also ensures on-site efficiency and client satisfaction. At QCM, we’re committed to helping you achieve flawless results—because every step matters.

Ready to upgrade your formwork system? Explore QCM’s magnetic solutions designed for durability, precision, and speed. Contact us today to learn how our products can transform your precast workflow.