How do fixing sockets with cross pins handle high tensile and shear loads?

2024-11-04

Fixing sockets with cross pins are engineered to effectively handle high tensile and shear loads in precast concrete applications. Their design and material properties contribute significantly to their load-bearing capabilities.

Mechanisms for Handling Loads

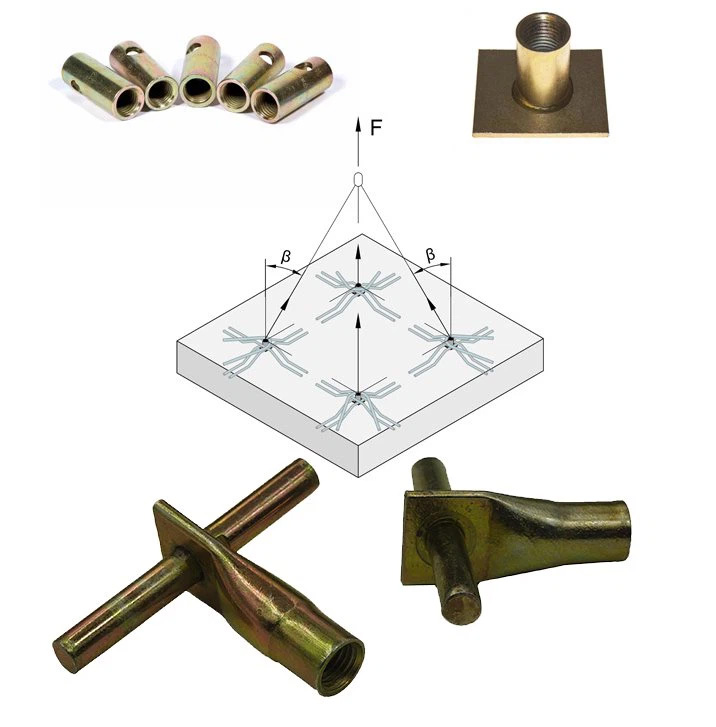

- Robust Construction: These sockets are typically made from solid rod materials, which provide the necessary strength to withstand high loads. The solid construction allows them to resist deformation under stress, ensuring they maintain their integrity during lifting operations.

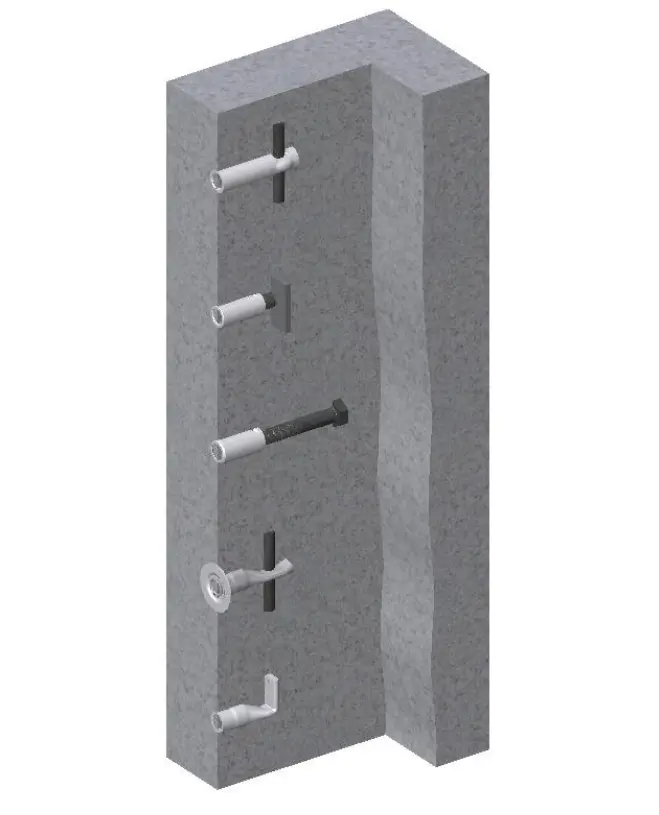

Application of Fixing systems

- Cross Pin Design: The inclusion of a cross pin is crucial as it serves to transfer forces directly into the concrete. This design alleviates the need for additional reinforcement, as the pin anchors itself within the concrete through form closure, effectively distributing the load across a larger area of the precast unit.

- Safe Working Load (SWL): Fixing sockets are rated for specific safe working loads, which indicate the maximum load they can handle safely. For example, some models can support loads ranging from 200 kg to over 3000 kg depending on their size and specifications. This rating is determined after applying safety factors based on testing data, ensuring reliability in practical applications.

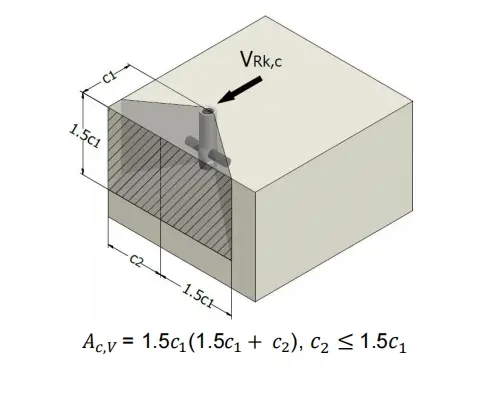

𝐴𝑐,𝑉 of concrete cone for an insert anchor

- Material Specifications: The sockets are often manufactured from high-grade steel, either zinc-plated mild steel or stainless steel, enhancing their durability and resistance to corrosion. This is particularly important in environments where moisture or chemicals may be present.

- Concrete Strength Requirements: For optimal performance, these sockets require the concrete in which they are embedded to have a minimum compressive strength (often around 25 N/mm²). This ensures that the concrete can adequately support the forces transmitted through the socket without cracking or failing.

Applications and Benefits

- Versatile Use: Fixing sockets with cross pins are widely used for lifting various precast elements such as walls, beams, and slabs. Their design allows for generous placement tolerances, making them suitable for projects where precise alignment may be challenging.

- Efficiency in Installation: These sockets facilitate quick connections between precast units, streamlining the construction process. Their ability to handle high loads while being easy to install makes them a preferred choice in precast concrete construction.

Application of fixing sockets with cross pin

In summary, fixing sockets with cross pins manage high tensile and shear loads through their robust design, effective force transmission via cross pins, and adherence to material and concrete strength specifications. This combination ensures safety and efficiency in precast concrete applications.