0102030405

How do environmental conditions affect the performance of shuttering magnets?

2024-12-18

Before discussing the effect of environmental conditions on the performance of shuttering magnet, we need to make it clear that the crux of the matter is the internal Nd2 Fe 14 B magnet. Environmental conditions can seriously affect the performance of Nd 2 Fe 14 B. The following are the main ways in which these conditions affect its functioning:

Temperature Effects

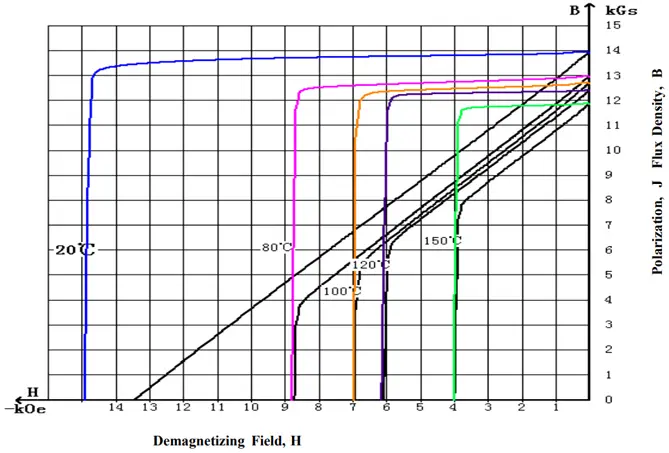

High Temperatures: NdFeB magnets have a maximum operating temperature of about 80°C. The coercivity of NdFeB magnets is high at room temperature. NdFeB magnets have a high coercivity at room temperature, which decreases dramatically as the temperature rises above 100 °C (212 °F) up to the Curie temperature (about 320 °C or 608 °F). If the temperature exceeds this critical value, the magnetic domains within the magnet become misaligned, resulting in a sharp decrease in magnetic force. Prolonged exposure to high temperatures can lead to permanent demagnetization, which severely affects the magnet's ability to hold up.

NdFeB magnet N48M (magnetic properties, demagnetization curve, temperature characteristics)

Low Temperatures: Conversely, low temperatures can enhance the magnetic strength of certain materials, although extreme cold can also lead to brittleness and potential cracking of the magnet structure. Care must be taken to ensure that magnets are not subjected to rapid temperature changes that could cause thermal shock.

Humidity and Moisture

Corrosion Risk: High humidity environments increase the risk of corrosion, especially if the magnets are not properly coated or protected. Sintered NdFeB is susceptible to corrosion, especially at the grain boundaries of the magnet. This corrosion can lead to serious damage, including fragmentation of the magnet into a powder of small magnetic particles, or flaking of the surface layer. Severe reduction in magnetic attraction, and thus magnet performance, can occur. Regular maintenance and protective coatings are essential to mitigate these effects.

Concrete Sensitivity: Given that concrete production is sensitive to humidity levels, shuttering magnets may also require protective measures in humid environments to prevent moisture-related damage. This is particularly important as moisture can affect both the concrete mix and the performance of the magnets themselves.

Surface Conditions

Cleanliness: The effectiveness of shuttering magnets is heavily reliant on the cleanliness of both the magnet and the surface it adheres to. Dirt, debris, or concrete residue can create air gaps that weaken magnetic attraction. Ensuring that surfaces are clean and free from contaminants is crucial for maintaining optimal performance.

Surface Flatness: Uneven or rough surfaces can also hinder the effectiveness of shuttering magnets. Any irregularities may lead to gaps that reduce the contact area between the magnet and the steel surface, thereby diminishing holding strength.

Maintenance Considerations

Regular Inspections: Environmental conditions necessitate regular inspections and maintenance of shuttering magnets. This includes checking for visible damage, cleaning surfaces, and ensuring that protective coatings remain intact. Neglecting these maintenance needs can lead to decreased performance over time.

In summary, environmental conditions such as temperature extremes, humidity levels, surface cleanliness, and flatness play critical roles in determining the performance of shuttering magnets. Proper management of these factors is essential for ensuring their effectiveness and longevity in precast concrete applications.