How do shuttering magnets improve the efficiency of concrete pouring?

Shuttering magnets streamline concrete pouring by offering quick installation, strong hold, adjustability, and reuse, enhancing safety and efficiency on construction sites. They reduce installation time, prevent formwork displacement, and expedite formwork removal, thus improving project turnaround times.

How do environmental conditions affect the performance of shuttering magnets?

Environmental conditions significantly impact shuttering magnet performance, with temperature affecting magnetic force, humidity increasing corrosion risk, and surface conditions like cleanliness and flatness influencing adhesion. Regular inspections and maintenance are crucial for optimal performance and longevity in concrete applications.

What are the technical standards for precast concrete magnets in the US

In the U.S., precast concrete magnets are regulated by organizations like ASTM and PCI, ensuring safety and effectiveness through standards like ASTM C27 and ACI 318. Technical requirements include load capacity, magnetic strength, and environmental adaptability. Reuse criteria involve material durability, protective coatings, regular inspections, and adherence to manufacturer's recommendations.

What challenges may shuttering magnets encounter during construction?

Shuttering magnets face challenges in precast concrete construction, including surface preparation, temperature sensitivity, mechanical load limits, corrosion, handling, storage, and compatibility issues, impacting their performance and efficiency.

What are the advantages of using shuttering magnets over traditional methods?

Shuttering magnets offer significant advantages in precast concrete production, including speed, efficiency, no damage to formwork, cost reduction, versatility, improved safety, high precision, ease of use, and environmental benefits, making them a superior choice over traditional fastening methods.

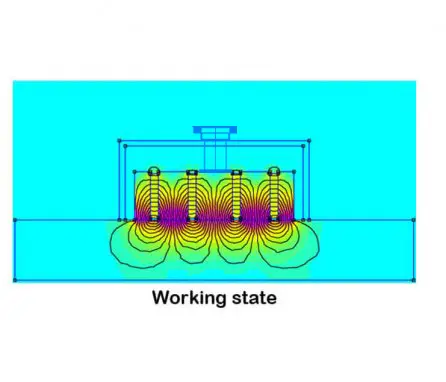

Magic Box ——precast magnet

The precast magnet is made of high-performance neodymium iron boron material, which can generate strong suction force without external power supply. When working, the bottom of the magnet closely fits with the precast concrete platform and releases the magnetic force through a lever, making it easy to move manually. Easy to operate, suitable for different environmental conditions, can be connected with different shapes of formwork, and the magnetic force can theoretically be maintained permanently. Platform thickness and surface flatness affect the magnetic suction force.

How does the switchable feature of a shuttering magnet work?

Switchable shuttering magnets offer easy control over magnetic force for formwork setup and removal in precast concrete, enhancing safety and efficiency through a simple push-button mechanism.

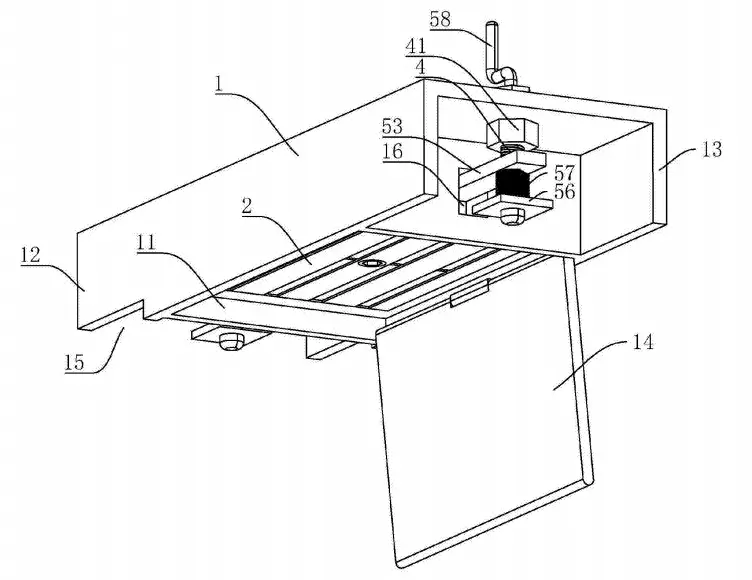

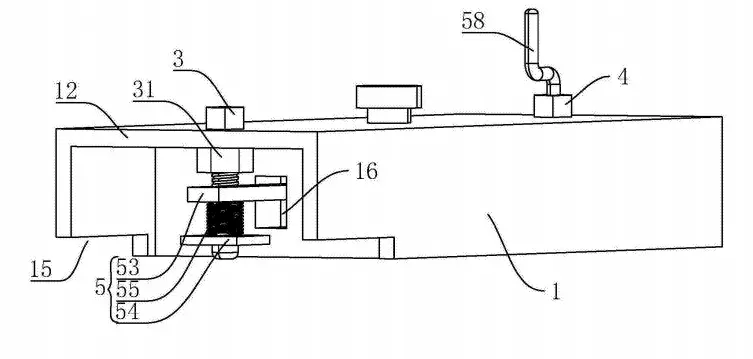

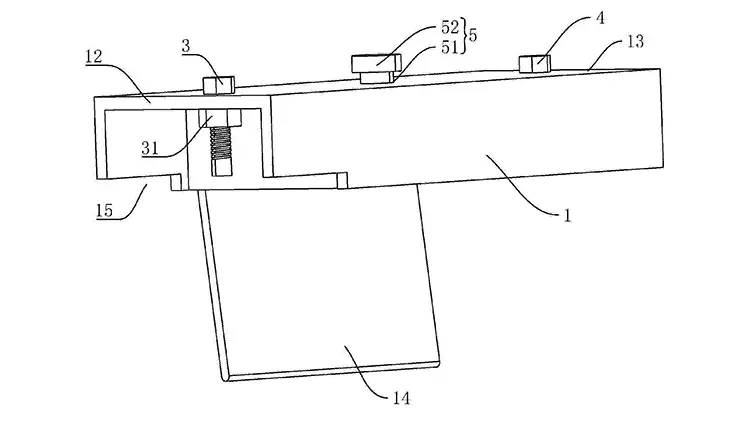

Mode of Specific Implementation 1 of the New Patent for Shuttering Magnet

This passage details a shuttering magnet patent. It has a C-shaped non-magnetic frame with a magnet groove. Has pressing & supporting ends, a cover plate, and an elevating mechanism to prevent slipping.

Explanation of the Utility Model Patent for Shuttering Magnet

The Utility Model Patent for Shuttering Magnet provides a magnetic box holder. It has C-shaped non-magnetic frame with magnet groove and permanent magnet. Further details like press and support mechanisms, lifting mechanism, etc. ensure easy formwork fixing and reduce damage. Illustrations show its various aspects.

Patent claim for a new type of shuttering magnet

A magnetic box fixer has a C-shaped non-magnetic fixing frame, a built-in permanent magnet, and two ends are respectively a clamping end and a supporting end, and is fixed by a bolt and nut structure. The depth of the magnet groove is greater than the thickness of the magnet, and a lifting mechanism is provided to adjust the position of the magnet. The magnetic box is also provided with a limit plate and a reset spring, as well as an adjustable arc-shaped supporting bolt to ensure the stability of the fixation.