What is a precast concrete fixed magnetic box

Precast concrete magnet is an efficient and convenient fixing device emerging from the process of modern construction industrialization. It cleverly utilizes the principle of magnetism to provide an innovative solution for the fixing and rapid installation of concrete frames.

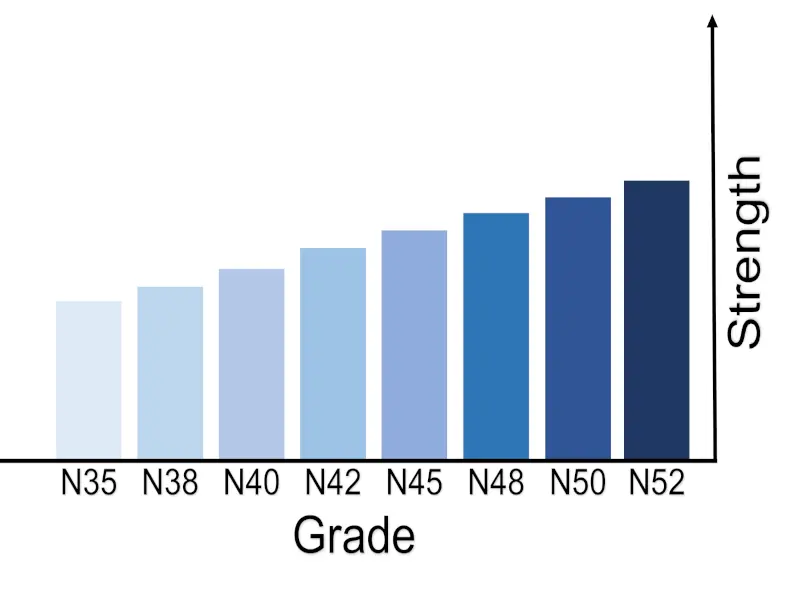

What is the difference between neodymium magnets N35 and N52?

Neodymium magnets are graded by strength, with N35 to N52 indicating increasing power; N52, the strongest, is used in high-performance applications.

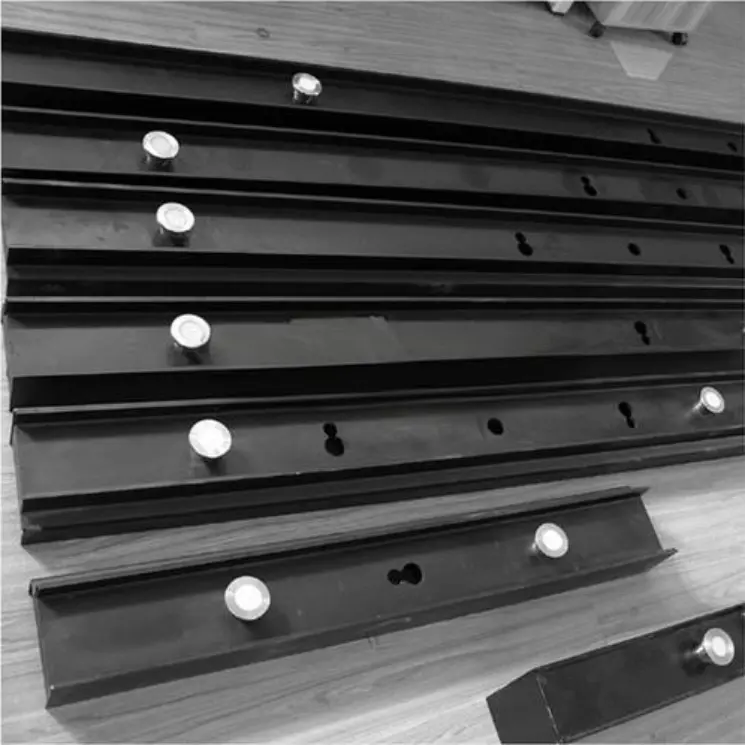

What are the benefits of using magnets in the H-profile magnetic shuttering system

The H Profile Magnetic Shuttering System boosts precast construction efficiency with rapid, strong, and versatile magnetic setups, reducing labor costs, minimizing damage, and enhancing safety.

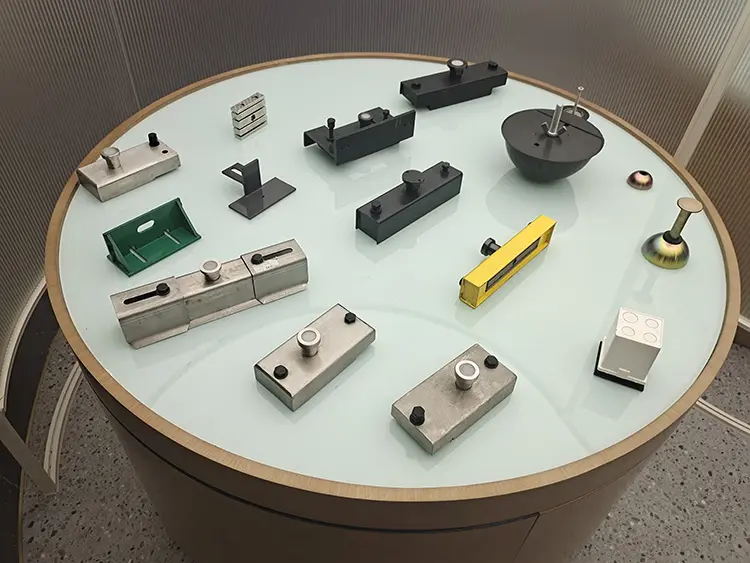

How does the 1.3T spherical head magnetic former compare to other lifting anchors?

The 1.3T Spherical Head Magnetic Former is a precast concrete lifting anchor that offers quick installation and removal, but traditional anchors provide higher load capacities and are more durable for heavy-duty applications.

Can precast concrete magnets be used in all types of construction projects?

Precast concrete magnets enhance construction efficiency and safety in various projects, providing precise mold fixation, reinforcement positioning, and quick assembly. They are ideal for infrastructure and modular construction, but their suitability varies with project requirements and environmental conditions.

Why is QCM Shuttering Magnet the best choice for precast concrete magnet?

QCM Shuttering Magnet has multiple advantages. Its magnet, with key properties like residual magnetism Br and coercivity Hcj, meets standards. The magnetic block uses high-quality materials and a precise production process. The shell offers material choices, and a thickened magnetic switch ensures durability, guaranteeing strong suction.

What is chamfer used for on precast concrete?

Chamfers, 45-degree beveled edges, improve safety, durability, and aesthetics across industries, notably in construction and architectural design.

What materials are used in the construction of shuttering magnets?

Shuttering magnets are vital in precast concrete industry. Comprising neodymium magnets for strong hold, steel casing for protection & stability, fixing screws & control, plus plastic/epoxy coating, they ensure efficient, safe concrete pouring.

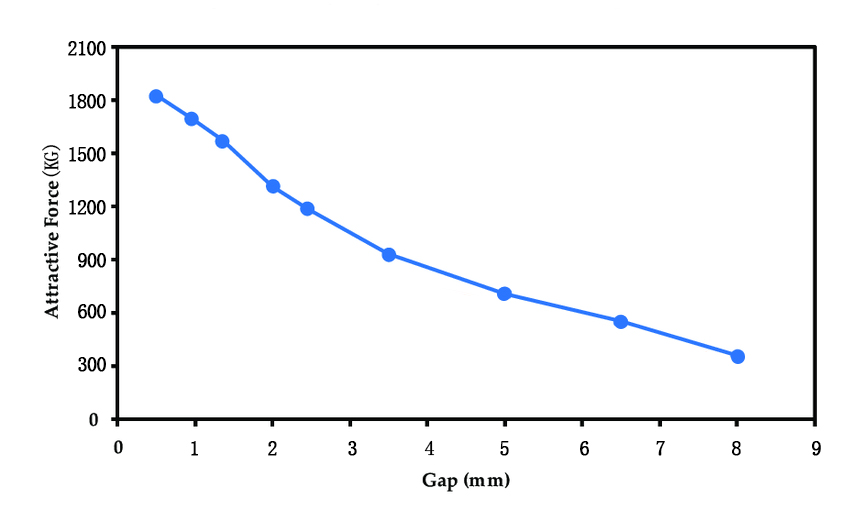

How does the air gap affect the performance of shuttering magnets?

Air gaps between shuttering magnets and ferromagnetic surfaces significantly reduce magnetic pull, affecting construction tool effectiveness. Material type and precision in application are key to optimizing performance.

Can shuttering magnets be used for other types of construction materials?

Shuttering magnets are versatile in construction, securing steel panels, wooden and aluminum formwork, masonry, and decorative materials. They offer time efficiency, cost savings, enhanced safety, and quality control across diverse building applications.