01

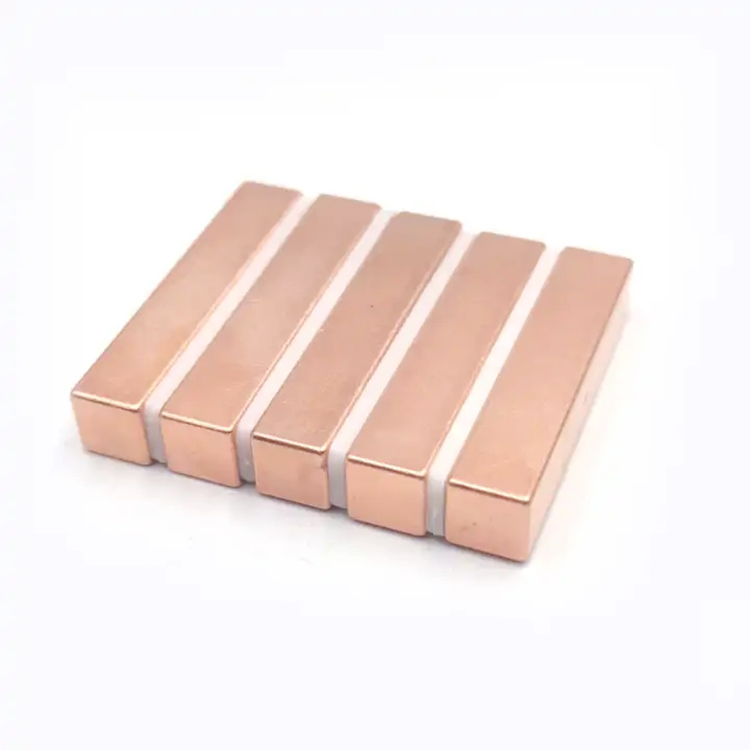

High Temperature Resistance Smco Magnet Custom Block Coating Magnet

Description

Product Introduction

Rectangular high-temperature strong magnets made from SmCo5 and Sm2Co17 magnetic steel offer exceptional performance in elevated-temperature environments. These magnets feature a high magnetic energy product, robust coercivity, and superior heat resistance, making them ideal for applications requiring stable magnetic properties under extreme conditions.

The magnets are available with custom coatings, including nickel-copper-nickel, zinc, gold, and epoxy, to enhance corrosion resistance and durability. With a working temperature range of 250–350°C, they maintain reliable performance in high-heat industrial settings. Magnetization directions can be customized to axial, radial, or radial multipole orientations to meet specific design requirements.

Product Description

Key Features

Material Composition: Constructed from SmCo5 and Sm2Co17 (rare-earth magnetic steel), renowned for their high-temperature stability and strong magnetic properties.

Shape: Standard rectangular block design, customizable for precision industrial applications.Other shapes can be customized.

Coatings: Protective coatings (nickel-copper-nickel, zinc, gold, epoxy, etc.) provide enhanced resistance to corrosion and thermal degradation.

Magnetic Performance:

High coercivity ensures resistance to demagnetization in harsh environments.

Customizable magnetization directions (axial, radial, radial multipole) for versatile engineering solutions.

Temperature Resistance: Operates reliably at 250–350°C, maintaining structural and magnetic integrity without significant performance loss.

Application Relevance

In modern industrial production, machinery and components often face high-temperature and high-impact conditions. These SmCo magnets are engineered to thrive in such environments, delivering consistent magnetic performance where standard materials fail. Their robust design and coating options make them suitable for applications in aerospace, automotive engines, industrial motors, and high-temperature sensors.

Quality Assurance

Rigorous testing ensures the magnets meet stringent standards for thermal stability, chemical resistance, and mechanical strength. Laboratory evaluations include:

Thermal cycling to validate performance across the full operating temperature range.

Corrosion testing to assess coating durability in aggressive environments.

Magnetic property analysis to confirm consistency in coercivity and magnetic energy product.

By prioritizing material science and precision engineering, these SmCo magnets offer a reliable solution for high-temperature applications, ensuring long-term functionality and safety in demanding conditions.