Formwork magnet Systems with one chamfer

product detail

The formwork magnetic system is gaining more and more attention in precast plants because it can significantly increase the production speed of concrete elements. The system uses strong built-in neodymium magnets to hold it in place, and the closed structure extends the service life of the system.

Key Features of Formwork Magnet Systems

Magnetic Technology

- High holding force: The formwork magnet system has multiple NdFeB magnet arrays built in, which can generate strong adhesion after being adsorbed on the steel platform, ensuring that the system will not shift during the pouring and curing of concrete. The adhesion generated by each magnetic array varies according to the model, generally 400kg to 3000kg, and can also be customized according to user needs.

- User-friendly design: The push button switch on the top of the magnetic array allows quick on and off settings, allowing workers to operate easily and safely.

- Precise alignment: The precise positioning characteristics of the system are derived from the high adhesion of the magnets, which can provide precise alignment whether producing prefabricated panels, walls or columns. The firm positioning without movement is the guarantee to ensure product consistency.

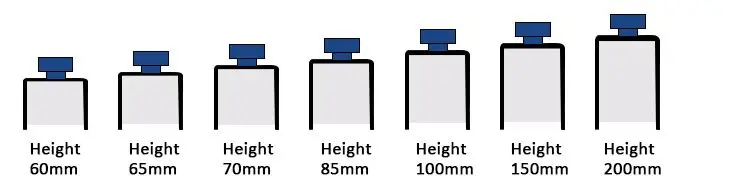

Height of formwork magnet

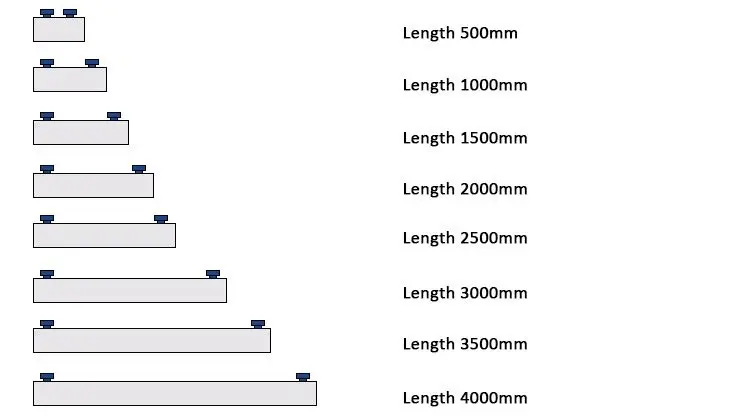

Length of formwork magnet

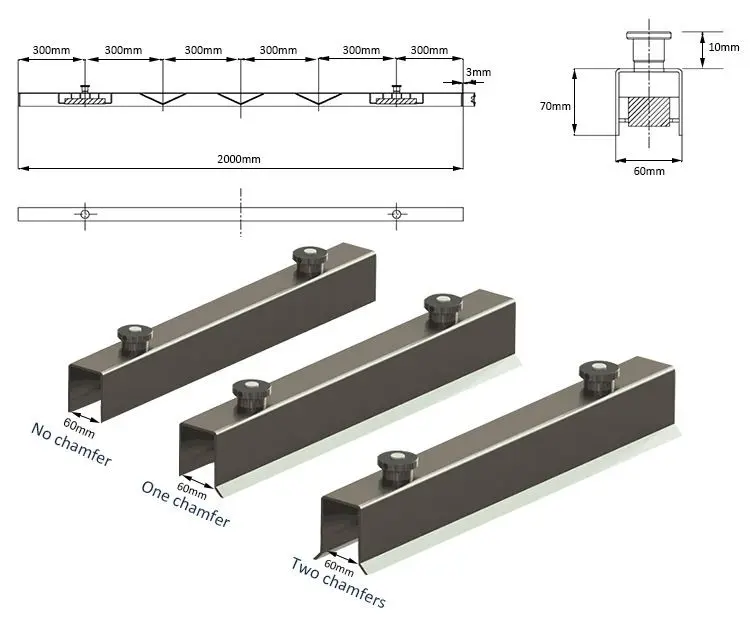

Types of formwork magnets

Advantages of Using Formwork Magnets

- Improve efficiency: Use magnetic force to fix the entire system, replacing traditional welding or bolts. This speeds up the assembly and disassembly of the formwork, thereby shortening the production cycle.

- Cost savings: The magnetic formwork system can save a lot of money. Why? Because it reduces labor costs. In addition, it reduces material waste, and does not require adhesives or a lot of hardware. Over time, this can save a lot of money. In addition, the magnetic formwork system can be reused, which also reduces the overall cost of precast concrete production.

- Versatility: The magnetic formwork system is versatile. It can adapt to prefabricated elements of various shapes and sizes, and it can be used in any construction project. Moreover, it can be used with different types of formwork materials, such as steel, wood and plastic.

Applications

Formwork Magnet Systems are primarily used in:

- Precast Concrete Production: Formwork Magnet Systems hold formwork securely in place, which facilitates the fabrication of walls, beams, slabs and other precast concrete parts.

- Construction Sites: On construction sites, where frames often have to be repositioned, these systems come into play with their flexibility, fast and precise fixing of frames without damaging existing structures or surfaces.

Application of Formwork magnet

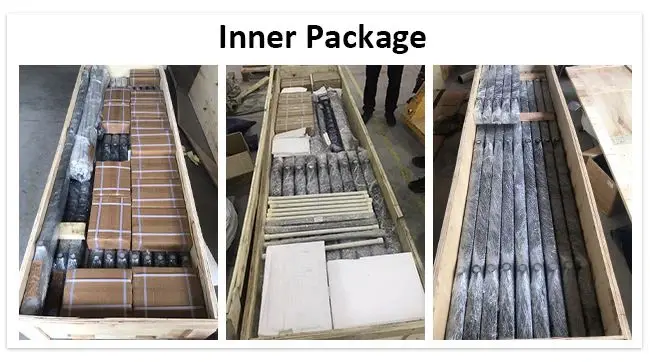

Shipping and packaging

Our Factory