0102030405

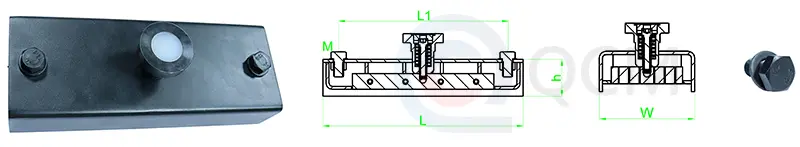

Carbon steel housing magnet shuttering

Magnets for formworks, specifically known as shuttering magnets, are innovative tools for fixing concrete formwork. These magnets can quickly position the formwork without the use of traditional fastening methods such as welding or bolts, greatly improving production efficiency and safety.

Key Features of Shuttering Magnets

- Magnetic Strength: QCM's Shuttering magnets utilize powerful neodymium magnets, which provide a strong adhesive force, ranging from 450 kg to over 3000 kg. This strength ensures that the formwork remains securely in place against the pressure of wet concrete.

|

|||||||

|

Model |

L(mm) |

L1(mm) |

W(mm) |

h(mm) |

M |

Weight(g) |

Breakaway(kg) |

|

QCM450 |

170 |

135 |

60 |

43 |

M12*30 |

1800 |

450 |

|

QCM600 |

170 |

142 |

60 |

43 |

M12*30 |

2500 |

600 |

|

QCM900 |

280 |

244 |

60 |

43 |

M12*30 |

2800 |

900 |

|

QCM1600 |

290 |

240 |

120 |

60 |

M16*30 |

6500 |

1600 |

|

QCM1800 |

320 |

270 |

120 |

60 |

M16*30 |

7200 |

1800 |

|

QCM2100 |

320 |

270 |

120 |

60 |

M16*30 |

7600 |

2100 |

|

QCM2400 |

320 |

270 |

120 |

60 |

M16*30 |

7600 |

2400 |

|

QCM3000 |

320 |

270 |

140 |

60 |

M16*30 |

7800 |

3000 |

- Design and Operation: Shuttering magnets feature a compact and lightweight design, making them easy to handle. They come with an on/off mechanism that allows operators to quickly activate or deactivate the magnetic force. This feature simplifies the process of adjusting and repositioning the magnets as needed.

- Materials: The construction of shuttering magnets involves:

- Neodymium Magnets: For strong magnetic attraction.

- Steel Casing: To protect the magnets and enhance their durability.

- Control Mechanisms: Such as push buttons or levers for easy operation.

Applications

Shuttering magnets are widely used in various applications within precast concrete production, including:

- Fixing side rails and blockouts in formwork.

- Securing molds for wall panels, columns, and other precast elements.

- Facilitating quick changes in formwork configurations to accommodate different designs.

Advantages

1. Efficiency: They significantly reduce setup time for formwork, allowing for faster production cycles.

2. Versatility: Suitable for use with both steel and wooden formworks, making them adaptable to various project requirements.

3. Non-destructive: By eliminating the need for drilling or welding, shuttering magnets preserve the integrity of the formwork surfaces.

4. Cost-effective: Their reusability and reduced labor requirements contribute to lower overall project costs.