In the world of construction and precast concrete applications, the integration of advanced technologies is paramount for efficiency and effectiveness. Among these innovations, the Neodymium Precast Concrete Magnet stands out due to its superior magnetic strength and versatility. These magnets have revolutionized the way concrete elements are manipulated, positioned, and secured during fabrication, making them indispensable tools for modern construction projects.

Understanding how to effectively utilize Neodymium Precast Concrete Magnets can significantly enhance workflow and productivity. By leveraging their robust magnetic properties, contractors and engineers can streamline the assembly process, improve safety measures, and ensure precise alignment of precast components. This introduction will delve into the strategic applications and best practices for using Neodymium Precast Concrete Magnets, providing insights that can lead to more efficient project execution and overall enhanced structural integrity.

Whether you are a seasoned professional or a newcomer in the construction industry, mastering the use of Neodymium Precast Concrete Magnets can empower you to take full advantage of their capabilities. This guide will cover essential techniques, considerations, and tips to ensure that your projects benefit from these remarkable magnetic tools, ultimately leading to superior outcomes in precast concrete construction.

Neodymium magnets are increasingly being utilized in precast concrete applications due to their exceptional strength and versatility. These powerful magnets can significantly enhance the efficiency of construction projects by facilitating the assembly and positioning of precast elements. Understanding how to effectively utilize neodymium magnets in conjunction with precast concrete can lead to improved productivity and reduced labor costs. Their magnetic strength allows for secure connections between panels and forms, minimizing the need for additional mechanical fastening which can be time-consuming and costly.

When implementing neodymium magnets in precast concrete, it is essential to consider their placement and orientation. Proper positioning ensures maximum magnetic attraction, allowing for stable and reliable connections. Additionally, the selection of the appropriate size and grade of magnet is crucial; higher-grade neodymium magnets can provide stronger adhesion, accommodating various forms and thicknesses of concrete.

Furthermore, understanding the environmental factors, such as temperature and moisture, can help in selecting magnets that will perform reliably in different conditions. Through careful planning and execution, neodymium magnets can greatly enhance the efficiency and effectiveness of precast concrete projects.

Neodymium magnets have gained popularity in construction projects for several compelling reasons. One of the primary benefits is their exceptional strength-to-size ratio, allowing them to securely hold heavy precast concrete components together without taking up much space. This feature not only improves efficiency during the assembly process but also reduces the risk of misalignment, ensuring that structures are built accurately and safely. The powerful magnetic attraction allows for quicker setup and repositioning of components, enhancing the overall productivity of construction teams.

Additionally, using neodymium magnets can lead to increased safety on job sites. The ease of handling and installation reduces the reliance on traditional fastening methods, which often require tools like drills or welders. This minimizes the potential for accidents associated with these tools and creates a cleaner, less cluttered work environment. By simplifying the connection of precast elements, neodymium magnets also enable faster project completion times, allowing contractors to meet deadlines without compromising on quality or safety. This innovative approach is transforming construction practices, making projects more efficient and cost-effective.

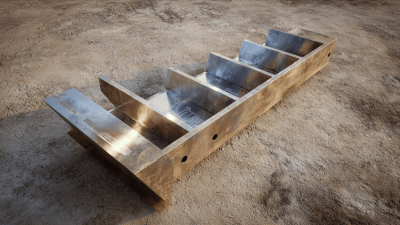

When selecting the appropriate neodymium magnet size for your precast concrete projects, it is essential to consider the specific requirements of your application. Neodymium magnets come in a variety of shapes and sizes, each with a different pulling force, which typically varies based on the magnet's dimensions and grade. For effective use, you should analyze the weight and dimensions of the concrete elements you are handling to determine the strength necessary for reliable hold. This analysis ensures that the magnets will not only support the weight but also reduce the risk of slippage during transportation and installation.

Moreover, the placement of these magnets is crucial for optimizing their effectiveness. Positioning larger magnets at critical stress points can enhance stability, while smaller magnets can be utilized in areas that require less support. Additionally, it is important to account for the surface condition of the concrete. Smooth and clean surfaces will yield better magnetic contact, thus achieving a stronger hold. Therefore, understanding the relationship between the size and placement of neodymium magnets, coupled with the characteristics of the concrete, will lead to more efficient and successful precast concrete projects.

| Magnet Size (mm) | Pull Force (lbs) | Ideal Applications | Notes |

|---|---|---|---|

| 20 x 10 | 30 | Small Fixtures | Low pull force, suitable for light applications. |

| 30 x 15 | 75 | Precast Panels | Optimal for concrete panel handling and placement. |

| 50 x 25 | 150 | Heavy Machinery | Suitable for lifting heavy concrete forms. |

| 75 x 38 | 300 | Large Panels | Designed for large precast structures. |

When using neodymium precast concrete magnets, proper installation is crucial to maximize their effectiveness in construction projects. First, ensure that the surfaces of the concrete are clean and free from debris or moisture. This preparation step allows for optimal magnetic contact, which is essential for the magnets to adhere securely. Applying a thin layer of non-corrosive adhesive can enhance the bond between the magnet and the concrete, further improving strength.

Next, pay attention to the orientation and placement of the magnets during installation. Position them strategically to align with the forces they will encounter; for example, placing them at the corners or points of stress can distribute weight and enhance stability. Additionally, consider the environmental factors, such as temperature and humidity, as they can affect the performance of the magnets. Regular inspection and maintenance of the installation will help ensure ongoing effectiveness, allowing for adjustments as necessary to maintain structural integrity.

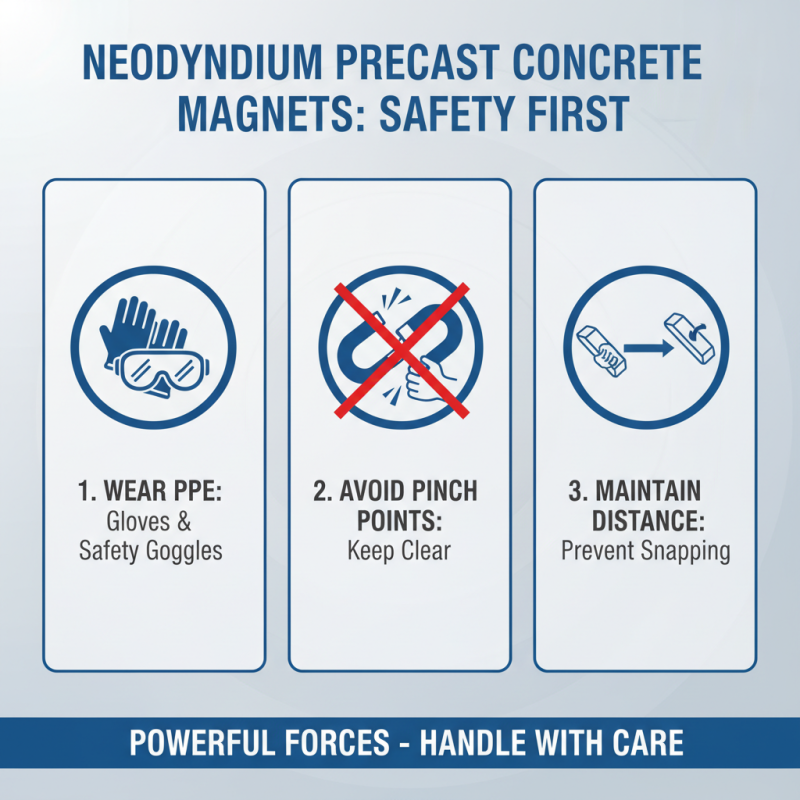

When working with neodymium precast concrete magnets, safety should always be a primary consideration. These powerful magnets can exert strong forces, which may pose risks if not handled properly. It’s essential to wear appropriate personal protective equipment, such as gloves and safety goggles, to shield against unintentional pinching or flying debris during the placement of magnets. Additionally, it is advisable to maintain a safe distance when handling multiple magnets, as their attraction can cause them to snap together unexpectedly, leading to potential injuries.

Another important safety aspect is the management of magnetic fields. Neodymium magnets can disrupt electronic devices, so it's crucial to keep them away from sensitive equipment. Workers should also be instructed on the dangers of working near ferromagnetic materials, which can become projectiles in high-strength magnetic fields. To further mitigate risks, establish a workspace that is free of unnecessary metallic objects and inform every team member about the operational procedures before starting the project. By incorporating these safety measures, the effectiveness of using neodymium magnets can be maximized while minimizing potential hazards in concrete applications.