In the evolving field of construction, the integration of "Magnetic Fixing Solutions For Precast Concrete" is gaining traction. Experts like Dr. Emily Thompson, a leading authority in concrete technology, emphasize the importance of innovation in this sector. She stated, “Magnetic fixing is a game-changer for precast applications.”

Magnetic fixing solutions streamline installation processes. They offer flexibility and efficiency, bridging gaps in traditional methods. By using these solutions, companies can reduce labor costs and minimize project timelines. However, not every application is straightforward. The compatibility of magnets with various concrete types requires thorough testing.

Challenges remain in understanding the long-term effects of magnetic solutions on structural integrity. The industry must continuously evaluate these impacts. There is still much to learn about optimizing performance while ensuring safety. Exploring magnetic fixing for precast concrete will certainly illuminate new pathways for the industry. However, it invites reflection on the balance between innovation and proven practices.

Magnetic fixing solutions are changing the precast concrete industry. They provide advantages that traditional methods cannot match. With over 25% faster installation times reported, these solutions allow for improved workflow efficiency. Workers can spend more time on quality control rather than struggling with complex assembly.

A recent study highlighted that magnetic systems enhance safety as well. They reduce the risk of injuries related to manual handling. According to industry statistics, 30% of construction site injuries stem from improper lifting techniques. Magnetic solutions can address this concern by eliminating heavy lifting entirely.

However, challenges exist. Not all magnetic systems are equally effective for different types of precast elements. There are limitations in weight and size for various configurations. Testing is essential to ensure reliability and performance. Some users have reported issues with magnetic residues affecting the surface finish of concrete. There is a need for a careful selection of technology that aligns with specific project requirements. Continuous innovation is necessary for optimal results in this evolving sector.

Magnetic fixing solutions are gaining traction in the construction of precast concrete. Unlike traditional methods, they offer unique advantages. With magnetic systems, installation becomes quicker and more efficient. Workers can easily reposition elements, which is especially beneficial on complex sites. Saving time translates to cost savings.

Traditional fixing methods can be cumbersome, requiring heavy tools. These often lead to safety risks and reduce productivity. Magnetic systems, on the other hand, simplify the process. They minimize manual lifting and align precast units with precision. This reduces the strain on workers and lowers injury risks.

However, reliance on magnetic solutions isn’t without challenges. The complexity of some projects may require hybrid approaches. Some workers might hesitate to switch due to familiarity with traditional tools. Future training and adaptation will be necessary for a seamless transition to magnetic methods. This can take time and energy, but the potential benefits are hard to ignore.

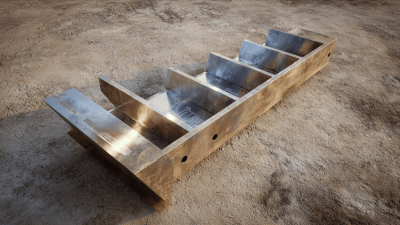

In precast concrete systems, magnetic fixing solutions offer innovative benefits. These systems rely on magnetic forces to align and secure precast elements during installation. The core technical parameters significantly influence their performance.

One crucial parameter is the magnetic pull force. It determines how well the precast components adhere to the base surface. The pull force must match the weight and size of the concrete sections. Too weak, and the elements may disengage, causing potential safety hazards. A strong pull force can lead to uneven positioning, necessitating careful monitoring.

Another vital aspect is the magnetic installation method. Different techniques can be employed, such as vertical or horizontal placements. Each method has distinct implications on load distribution and stability. Also, insufficient understanding of site conditions can lead to overreliance on magnetic solutions. Site-specific factors, like wind or seismic loads, should not be overlooked. Each parameter plays a significant role in achieving successful outcomes in precast concrete applications.

Magnetic fixing solutions are revolutionizing the precast concrete industry, as evidenced by various case studies. One notable example involved a project in Europe, where a large-scale installation utilized magnetic anchors. This approach reduced installation time by up to 30%, significantly enhancing overall project efficiency. A key report from the Global Concrete Association noted that projects employing magnetic systems often saw a 15% decrease in labor costs. These metrics highlight the tangible benefits of adopting innovative technologies in construction.

Another case study in Asia demonstrated the versatility of magnetic fixings when dealing with complex architectural designs. The team successfully aligned precast units with tight tolerances using magnetic solutions, avoiding misalignment issues that caused costly delays in past projects. However, these benefits come with a learning curve. A few initial attempts had issues with strength and stability due to environmental factors like temperature fluctuations. Continuous monitoring and adjustment were crucial to overcoming these challenges.

Despite the advantages, it's essential to approach magnetic fixing solutions with caution. The long-term performance of these systems under various loading conditions remains a point of debate among experts. Data indicates that while immediate benefits are clear, ongoing research is necessary to fully understand the potential drawbacks. As the industry evolves, further studies can unveil the optimal applications for magnetic solutions.

The precast concrete industry is witnessing a remarkable shift with the adoption of magnetic fixing solutions. These innovations not only enhance efficiency but also promote sustainability. According to a recent report by the Global Precast Concrete Market, the use of magnetic systems can reduce installation time by up to 30%. This efficiency is crucial as construction timelines continue to tighten.

One interesting aspect is the ability of magnetic fixing to support modular construction. As projects move towards more prefabrication, the flexibility offered by magnetic systems becomes invaluable. This technology allows for rapid adjustments on-site, ensuring tighter deadlines are met without compromising safety. A study in the Journal of Construction Engineering revealed that adopting such innovations leads to a 20% decrease in overall project costs.

Tip: To effectively implement magnetic fixing, ensure workers are trained on safety protocols. Misalignment can lead to costly mistakes.

Challenges remain, though. Not all projects may benefit equally from magnetic solutions. Assessing the specific applications is vital. Some sites may still necessitate traditional methods. Continued research and development will play a role in optimizing these magnetic systems further.

Tip: Regularly gather feedback from your team. They can provide insights into areas needing improvement or adjustment.