In the realm of precast concrete construction, Neodymium Precast Concrete Magnets have revolutionized the industry. According to Dr. Alex Henderson, a leading expert in construction technology, “Using Neodymium Precast Concrete Magnets properly can enhance efficiency significantly.” His insights shed light on how these powerful magnets can streamline operations and improve overall project outcomes.

However, the application of Neodymium Precast Concrete Magnets is not without challenges. Users often overlook proper magnet placement and handling, leading to potential mishaps. Maintaining precision is crucial for maximizing their effectiveness. The difference between success and failure can lie in simple details.

Understanding the strengths and weaknesses of Neodymium Precast Concrete Magnets requires experience and reflection. Many professionals face obstacles, yet learning from these experiences fosters growth. As the industry evolves, embracing both the advantages and limitations of these magnets will be key to unlocking their full potential.

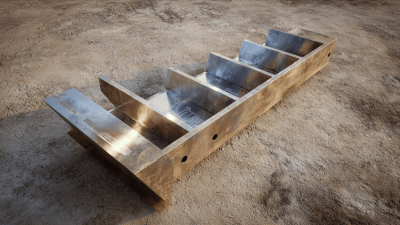

Neodymium precast concrete magnets have become popular in construction for their strength and utility. These magnets are made from a combination of neodymium, iron, and boron. Their strong magnetic pull allows them to easily hold concrete panels in place during construction. This reduces the need for additional supports, making the process more efficient.

Understanding how to utilize these magnets effectively is crucial. Placement matters. If the magnets are not positioned properly, they may not hold as intended, causing delays. It’s also important to consider the weight of the concrete pieces. Oversized panels may exceed the magnetic capacity, leading to potential mishaps. Regular inspections of the magnets are necessary to maintain safety. Tiny cracks can reduce their effectiveness and could lead to failures.

Using neodymium magnets also requires care. Magnetic fields can affect nearby electronics. Workers should be cautious about what tools they bring near these magnets. Training is essential. Not all crew members may be aware of the best practices. It's vital to address these points to prevent accidents.

When considering neodymium magnets for precast concrete applications, assessing their quality and strength is essential. The magnets should be produced using high-purity raw materials, as impurities can drastically reduce performance. A magnet's strength is often rated in terms of pull force, which indicates how much weight it can hold when attached to a flat surface. It’s crucial to test this in real conditions, as listed values can sometimes be misleading.

Inspect the coating on neodymium magnets. A sturdy coating prevents corrosion and enhances durability. If the coating chips or wears, the magnet's lifespan might be compromised. Conduct tests involving different thicknesses of concrete to gauge real-world applicability. Some magnets may work well on thinner slabs but struggle with heavier loads. Document these observations carefully, as understanding limitations leads to better future applications.

For precise applications, consider factors like temperature resistance. Neodymium magnets can lose strength in extreme heat. If used in a hot environment, thorough testing is critical. Verifying strength across a range of scenarios helps identify potential weaknesses. While neodymium magnets offer powerful advantages, smart usage relies on meticulous evaluation. Reflection on usage scenarios will reveal both the strengths and shortcomings of these materials.

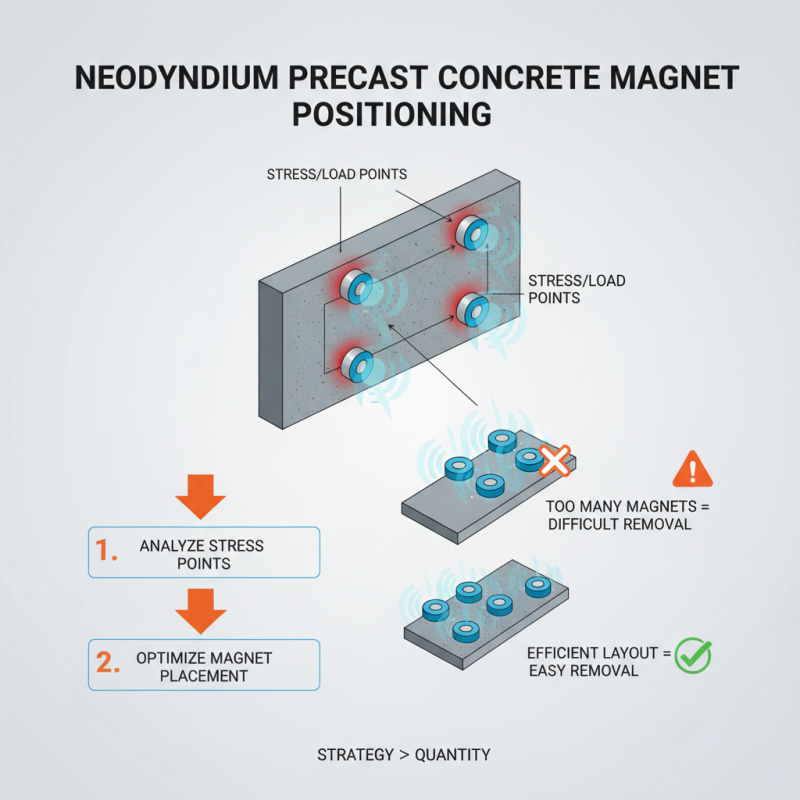

When positioning neodymium precast concrete magnets, it’s essential to consider the layout carefully. Start by determining where the loads and stresses will be concentrated in your concrete structure. This knowledge helps you position the magnets effectively. Using more magnets than necessary might seem like a good idea, but it can complicate the removal process later.

Tips: Always test the placement before finalizing. Use a temporary adhesive to hold the magnets in place during initial trials. Also, pay attention to alignments. Misalignments can lead to significant structural issues in the future.

Another aspect to remember is the environment. Neodymium magnets can lose some strength in extreme heat. Positioning them away from heaters or direct sunlight can preserve their effectiveness. You may think low visibility doesn’t matter, but hidden magnets can lead to challenges during maintenance.

Tips: Keep a record of where all magnets are placed. Creating a detailed map can save time during inspections. Regular checks on the magnets are also a good idea. Simple maintenance can prevent bigger issues down the line.

When working with neodymium magnets, safety is a top priority. These powerful magnets can be surprisingly dangerous if not handled properly. They have a strong pull and can snap together from a distance, potentially pinching fingers or causing injuries. Always keep them away from your face and ensure that children are supervised.

Use gloves when handling these magnets. The metal surface can be slick, and accidents may happen. If magnets collide, they can shatter, sending shards flying. This can lead to cuts or eye injury. If a magnet does break, you must clean up the area carefully. Small pieces can be hard to see and could pose a risk if ingested or stepped on.

Store the magnets safely. Use a designated container that is kept out of high-traffic areas. Neodymium magnets can lose their strength if exposed to extreme heat. Ensure that they are not near heated equipment. Regularly check for any signs of wear and tear. Taking these precautions will help you enjoy working with neodymium magnets while minimizing risks.

| Tip | Description | Safety Precautions | Recommendations |

|---|---|---|---|

| Proper Handling | Always handle neodymium magnets with care due to their strong pull. | Wear gloves to avoid pinching fingers. | Use a indexing tool to lift heavy magnets. |

| Storage | Store magnets in pairs to prevent them from attracting other items unexpectedly. | Keep away from electronic devices and sensitive instruments. | Use a magnetic keeper for long-term storage. |

| Usage in Concrete | Ensure the surface of concrete is clean for optimal magnet adhesion. | Be cautious of sudden pulls that may cause slips. | Test adhesion before executing heavy lifting tasks. |

| Dismantling | When removing, do so gradually to minimize snapping back. | Always stand clear while detaching magnets. | Use a lever or prying tool to assist with detaching. |

Proper maintenance and storage of neodymium magnets is essential for their longevity and optimal performance. Exposure to extreme temperatures can significantly weaken their magnetic properties. Industry data suggests that prolonged exposure above 80°C (176°F) can permanently demagnetize them. Therefore, storing magnets in a climate-controlled environment is crucial. Keeping them away from moisture will also prevent oxidation, which can deteriorate their quality over time.

When storing neodymium magnets, it's important to use protective materials. Wrap them in soft cloth or bubble wrap to avoid scratches. This ensures they maintain their strong magnetic surface. Additionally, using non-magnetic holders can prevent accidental demagnetization. Placing them in secure storage containers can also minimize the risk of unintentional impact. Many professionals overlook these simple precautions, leading to reduced efficiency and lifespan of their magnets.

Periodic inspections can further enhance the longevity of these magnets. Checking for chips or cracks can help identify potential issues early. This is especially important in heavy-duty applications, where reliability is crucial. Users often forget that small damages can lead to significant performance drops. Investing time in regular maintenance can yield long-term benefits and prevent costly replacements.