In the ever-evolving landscape of construction, precast concrete has emerged as a cornerstone for modern infrastructure, offering unparalleled durability and efficiency. As industry reports indicate, the global precast concrete market is projected to reach approximately $200 billion by 2025, emphasizing the growing demand for innovative and reliable construction solutions.

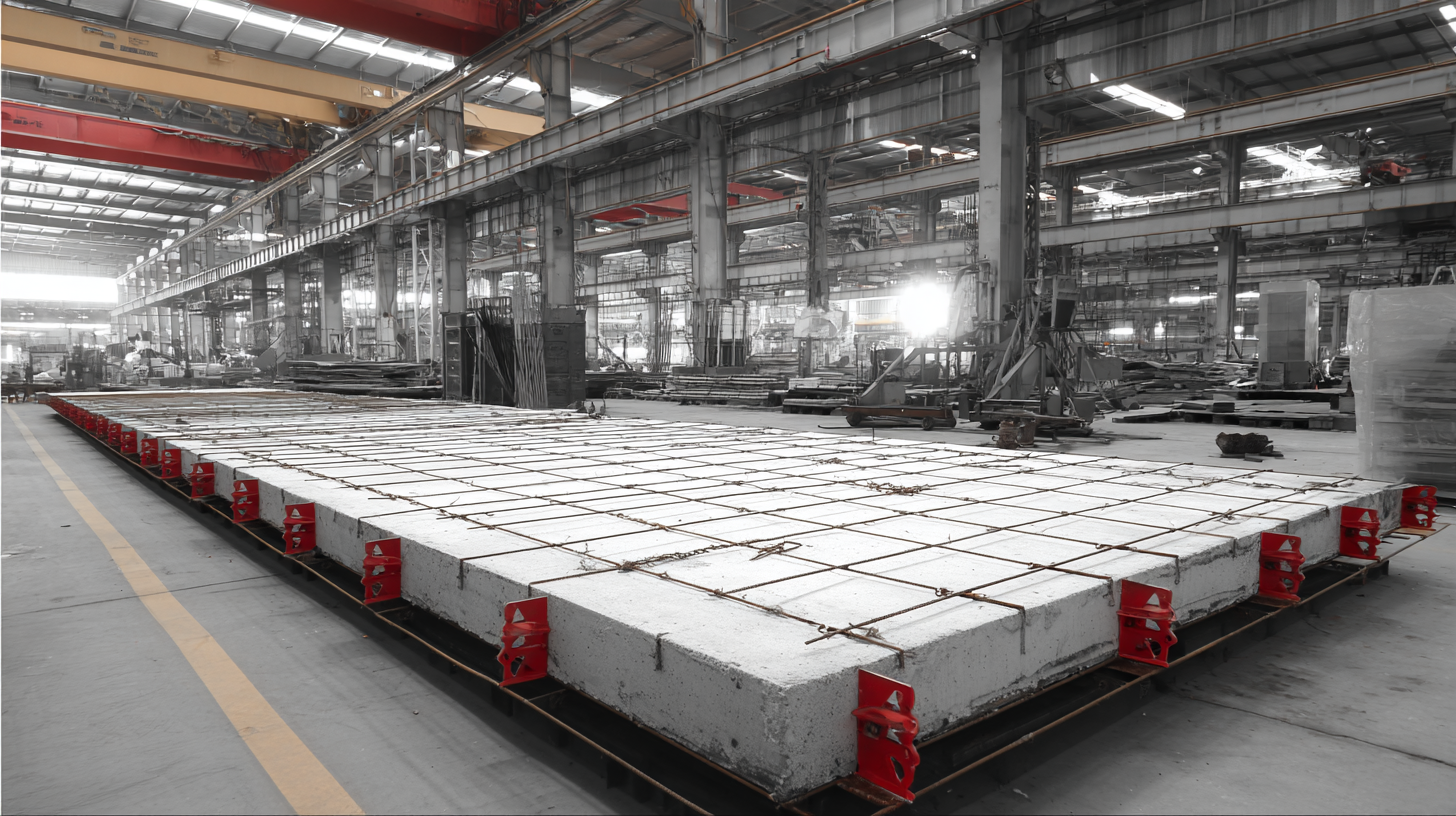

Among these innovations, Magnetic Fixing Solutions For Precast Concrete are gaining traction, providing a seamless method for assembling precast elements with precision and speed. This technology not only enhances the structural integrity of constructions but also streamlines the installation process, reducing labor costs and time significantly. By integrating these cutting-edge solutions from trusted manufacturers in China, the construction industry can ensure the unyielding quality and reliability that modern projects demand, paving the way for a resilient and sustainable future.

In the precast concrete industry, understanding the significance of import and export certifications is crucial for ensuring product quality and safety. These certifications not only enhance the credibility of manufacturers but also assure customers about the compliance with international standards. According to a report by the International Concrete Institute, about 70% of precast manufacturers emphasize the necessity of certifications for entering global markets, highlighting their role in facilitating smoother trade operations.

Tips: When assessing a precast concrete supplier, always inquire about their certifications and compliance with both local and international standards. This practice not only protects your investment but also guarantees that the products you receive meet rigorous quality benchmarks.

Moreover, the lack of appropriate certifications can lead to significant financial losses and project delays. The same report indicates that projects lacking certified materials often incur up to 30% more costs due to rework and regulatory issues. Thus, by prioritizing certified precast solutions, businesses can mitigate risks and foster long-term partnerships in the industry.

Tips: Regularly update your knowledge on certification requirements and trends in the precast industry, as these can change based on evolving regulations and market demands. Staying informed will position your business as a trustworthy player in the competitive landscape.

When it comes to precast concrete products, ensuring uncompromising quality is paramount. According to a recent report from the World Cement Association, the global precast concrete market is projected to reach $200 billion by 2025, driven by increasing infrastructure development and urbanization. With such rapid expansion, it becomes crucial that manufacturers adhere to essential guidelines throughout the production process to maintain high-quality standards.

One of the key factors in achieving quality in precast concrete is the use of reliable fixing solutions, such as magnetic fixing systems. These advanced solutions enhance both the efficiency and durability of construction projects. According to a study published by the National Precast Concrete Association, projects using innovative fixing systems saw a 30% increase in installation speed and a notable reduction in the incidence of structural failures. By investing in top-notch solutions from reputable suppliers, manufacturers can elevate their products and ensure they meet rigorous industry standards.

Magnetic fixing solutions have emerged as a game changer in the construction industry, offering unparalleled benefits for precast concrete applications. These innovative tools provide a secure and efficient method for attaching elements, ensuring precision and durability in every project. By utilizing magnetic technology, construction professionals can streamline their workflows, decreasing installation time while enhancing safety on site. This method allows for easy repositioning without damaging the materials, making it an ideal choice for complex projects.

Magnetic fixing solutions have emerged as a game changer in the construction industry, offering unparalleled benefits for precast concrete applications. These innovative tools provide a secure and efficient method for attaching elements, ensuring precision and durability in every project. By utilizing magnetic technology, construction professionals can streamline their workflows, decreasing installation time while enhancing safety on site. This method allows for easy repositioning without damaging the materials, making it an ideal choice for complex projects.

Tip: When using magnetic fixing solutions, ensure that the surface of the precast concrete is clean and free of any debris. This will maximize adhesion and prevent any unwanted movement during the curing process.

Moreover, the use of magnetic systems can lead to significant cost savings. Traditional fixing methods can involve multiple components and labor-intensive processes, whereas magnetic solutions minimize the need for additional materials. This simplicity not only reduces expenditure but also contributes to a cleaner job site, minimizing waste and enhancing overall project efficiency.

Tip: Always consider the weight and size of the precast elements when selecting the strength of magnetic fixings. Utilizing the right specifications ensures optimal performance and stability throughout the construction process.

When sourcing precast concrete from China, several key factors must be considered to ensure quality and reliability. First and foremost, it is crucial to evaluate the manufacturing standards of potential suppliers. Look for companies that adhere to international quality certifications such as ISO 9001, which guarantee that their products meet stringent quality requirements. Additionally, assessing the technology and equipment used in the production process can provide insight into the potential durability and precision of the precast concrete.

Another vital consideration is the reputation and experience of the supplier. Companies with a proven track record in the industry are more likely to deliver consistent quality. It’s advisable to review customer testimonials and case studies to gauge the satisfaction of previous clients. Furthermore, having transparent communication with the supplier about your specific needs and expectations can lead to a better understanding of their capabilities and foster a trustworthy relationship.

Finally, consider the logistics involved in the sourcing process. Shipping and delivery timelines can vary greatly, impacting your project schedules. Opting for suppliers with efficient logistics and localized facilities can reduce potential delays. By paying attention to these critical factors, you can confidently source high-quality precast concrete solutions that meet your project requirements.

The precast concrete industry is experiencing a transformative phase, largely due to innovations in magnetic fixing technologies. According to a recent report by the Global Precast Concrete Market Analysis, the adoption of advanced magnetic fixing solutions can reduce installation time by up to 50%, significantly enhancing overall project efficiency. These technologies allow for quick adjustments and repositions during the assembly process, leading to streamlined operations and minimized labor costs.

One particularly compelling aspect of magnetic fixing is its ability to ensure structural integrity while providing flexibility in design. The National Institute of Standards and Technology (NIST) has highlighted that precast concrete structures using magnetic fixing are less susceptible to misalignment, reducing the risk of structural failure. This innovation not only meets the growing demand for durability but also supports sustainable construction practices by optimizing material use.

**Tip 1:** When considering precast concrete options, look for suppliers who incorporate advanced magnetic fixing technologies to maximize efficiency.

**Tip 2:** Always verify certifications and industry compliance before selecting products, as this ensures you’re investing in quality solutions that prioritize safety and performance.

By harnessing the power of magnetic fixing, constructors can ensure not just speed, but high-quality results in their precast concrete applications.