The construction industry has increasingly turned to innovative materials and technologies to enhance structural integrity and efficiency. Among these advancements, the Neodymium Precast Concrete Magnet has emerged as a groundbreaking solution, combining the strength of precast concrete with advanced magnetic technology.

According to a recent report by MarketsandMarkets, the global precast concrete market is projected to reach USD 140.33 billion by 2026, driven by growing urbanization and infrastructure development.

Neodymium magnets, known for their remarkable strength-to-weight ratio, can significantly improve the holding capabilities and overall durability of precast concrete structures, offering solutions to common challenges faced in construction such as alignment, stability, and assembly speed.

By harnessing the power of Neodymium Precast Concrete Magnets, the industry can unlock new possibilities for safer, more resilient structures, making this technology a pivotal focus for engineers and builders alike.

Neodymium precast concrete magnets are a revolutionary advancement in construction and engineering, known for their remarkable ability to enhance the structural integrity of various projects. Composed of neodymium, iron, and boron, these magnets offer a unique combination of strength and durability, making them ideal for a range of applications. The high magnetic power of neodymium allows for secure connections without the need for additional mechanical fasteners, streamlining construction processes and reducing costs.

As the advanced magnetic materials market is projected to reach USD 52.6 billion by 2034, it is clear that the impact of magnetic technology is profound across industries. From optimizing load-bearing capabilities in infrastructure to facilitating innovative designs in precast concrete elements, neodymium magnets are at the forefront of this expansion. Their integration into modern technology not only supports enhanced performance but also drives sustainability by minimizing material waste and promoting efficient construction practices. The ongoing research and development in magnetic materials signify a promising future for neodymium magnets, particularly in enhancing structural systems in various sectors.

The integration of advanced magnetic technology in construction, especially through the use of neodymium precast concrete magnets, brings significant benefits that enhance structural integrity. These magnets leverage their powerful magnetic force to improve the bonding of precast elements. Data indicates that structures utilizing neodymium magnets can achieve up to a 30% increase in alignment precision, which is crucial during the erection phase of construction. This precision not only reduces construction time but also minimizes material waste, aligning with modern sustainability goals.

As industries increasingly seek alternatives to rare earth elements, the application of advanced magnetic technology in construction becomes more pertinent. Recent efforts in the electric vehicle sector to design motors with minimal reliance on rare earth elements reflect a broader trend towards innovative materials. Similarly, in construction, the advancements in magnetic technology promise a shift towards more efficient building practices. The use of high-performance neodymium magnets can potentially revolutionize how precast concrete components are assembled, enhancing overall structural resilience while simultaneously addressing concerns surrounding resource scarcity and environmental impact.

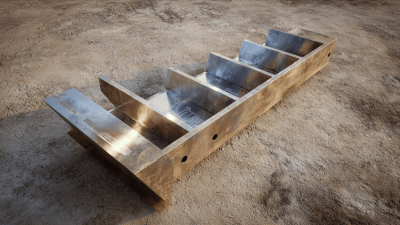

Implementing neodymium magnets in structural projects offers a revolutionary way to enhance the integrity and stability of concrete structures. The first step involves selecting the appropriate size and strength of neodymium magnets based on the specific requirements of your project. Factors such as the weight of the concrete elements, anticipated load, and environmental conditions must be carefully considered. It’s essential to consult with engineers who specialize in magnetic technology to ensure optimal integration.

Implementing neodymium magnets in structural projects offers a revolutionary way to enhance the integrity and stability of concrete structures. The first step involves selecting the appropriate size and strength of neodymium magnets based on the specific requirements of your project. Factors such as the weight of the concrete elements, anticipated load, and environmental conditions must be carefully considered. It’s essential to consult with engineers who specialize in magnetic technology to ensure optimal integration.

Once the magnets are selected, the next step is to integrate them into the precast concrete forms. This requires precise placement and secure anchoring of the magnets to ensure they remain effective throughout the lifecycle of the structure. Training workers on handling and installing magnets safely is crucial, as neodymium magnets possess significant strength that can pose safety risks. Finally, conducting thorough testing on the assembled structure will verify the practical benefits of using neodymium magnets, such as reduced tension stresses and improved alignment, ultimately leading to enhanced structural integrity.

Neodymium magnets have emerged as a revolutionary component in the field of precast concrete, offering remarkable enhancements to structural integrity and durability. By integrating these advanced magnets into concrete structures, engineers can improve the cohesion between elements, leading to stronger, more resilient assemblies. The inherent strength of neodymium helps in effectively distributing forces throughout the concrete, thus minimizing stress concentrations that can lead to cracking or failure.

The impact of neodymium magnets extends beyond mere adhesion; they also play a vital role in the longevity of concrete structures. By improving the overall stability of precast components, these magnets reduce the risk of structural degradation caused by environmental factors such as moisture and temperature fluctuations. Additionally, their lightweight yet strong properties allow for the design of more complex, innovative structures without compromising on safety or performance. As research progresses, the potential applications for neodymium magnets in construction continue to expand, paving the way for more durable and sustainable building practices.

| Property | Description | Impact on Structural Integrity | Durability Factor |

|---|---|---|---|

| Magnetic Force | High strength neodymium magnets provide superior holding capacity. | Enhances load-bearing capabilities, reducing potential failures. | Excellent; withstands environmental changes. |

| Corrosion Resistance | Coated to prevent corrosion, ensuring long-term stability. | Prevents deterioration of concrete structures. | High; maintains performance in adverse conditions. |

| Weight | Lightweight compared to traditional anchoring systems. | Reduces overall structure weight, enabling innovative designs. | Good; minimizes stress on supporting materials. |

| Ease of Installation | Simple setup requiring minimal tools for placement. | Reduces labor time and associated costs. | Very good; less disruption during construction. |

| Temperature Tolerance | Operates effectively in a range of temperatures. | Increases reliability in varying climates. | High; remains functional in extreme conditions. |

The construction industry is poised for a significant transformation by 2030, driven by advancements in magnetic technology, such as neodymium precast concrete magnets. These powerful magnets enhance structural integrity while simplifying assembly processes, thereby improving overall efficiency in construction projects. According to a recent review on energy storage systems, the integration of innovative technologies can vastly improve outcomes, with predictive maintenance powered by AI and machine learning being central to future trends in the sector. This aligns with the industry's shift towards sustainability and increased safety standards.

Tips: To maximize the benefits of advanced magnetic technology, consider implementing real-time monitoring systems that utilize these magnets for structural health assessment. Embracing wearables can further enhance worker safety and productivity, providing immediate feedback and data analytics for construction teams, thereby fostering a safer and more efficient work environment.

As the industry continues to adopt new technologies, embracing innovations not only boosts structural integrity but also aligns with global trends towards cleaner energy transitions. Research highlights that rare earth magnets are critical in driving sustainable practices, addressing bottlenecks in production while enhancing performance metrics in green construction solutions. This synergy creates a holistic approach that not only meets current demands but also paves the way for future advancements in construction technology.