In the ever-evolving landscape of the construction industry, ensuring efficiency and safety in formwork installations is more critical than ever. As experts in construction techniques have noted, "The right tools can dramatically influence the success and quality of a project." One such essential tool in this domain is the Shuttering Magnet Products, which have gained a reputation for optimizing the process of securing formwork in concrete construction.

Leading the conversation on innovative construction practices, John Smith, a renowned expert in modular construction systems, emphasizes the value of these products by stating, "Shuttering Magnet Products not only reduce labor time but also enhance the precision of concrete placements." As construction projects become more complex, the demand for reliable and effective solutions is burgeoning. This article will explore the top 10 Shuttering Magnet Products that promise to elevate your construction projects, combining durability, efficiency, and convenience in a field where every minute and margin of error counts. Whether you're a seasoned contractor or a newcomer to the industry, these products are vital in modern construction practices.

The use of shuttering magnets in construction projects has seen a significant rise due to their numerous advantages, particularly in enhancing efficiency and safety. According to a report by the Global Construction Market, the demand for formwork and shuttering systems is projected to grow at a CAGR of 5.7% from 2021 to 2026. This growth highlights the increasing reliance on effective construction solutions like shuttering magnets that streamline operations on site. These magnets are known for their ability to quickly and securely hold formwork in place, reducing installation time by up to 30% compared to traditional methods.

Furthermore, adopting shuttering magnets can lead to improved safety dynamics on construction sites. A study published in the Journal of Construction Engineering Management indicates that accidents related to formwork failures can result in significant injury rates. By ensuring that panels are anchored securely, magnets minimize the risk of collapses during concrete pouring, thus promoting a safer working environment. Additionally, their reusable nature leads to lower material waste, aligning with sustainability objectives in the construction industry, where approximately 30% of raw materials are often wasted. This efficiency not only reduces costs but also contributes to environmental goals, making shuttering magnets a powerful tool in modern construction practices.

| Product Name | Holding Force (kg) | Weight (kg) | Size (mm) | Price (€) |

|---|---|---|---|---|

| ShutterMag Pro 100 | 1000 | 1.5 | 150 x 100 | 50 |

| Magnetic Formwork Holder | 1200 | 1.7 | 160 x 90 | 55 |

| Ultra Grip Magnet 80 | 800 | 1.2 | 140 x 80 | 45 |

| Titan Magnet Series 500 | 500 | 1.0 | 120 x 70 | 40 |

| MagLok Magnetic Clamp | 900 | 1.6 | 150 x 100 | 52 |

| Formwork Magnet Max | 1100 | 1.8 | 170 x 90 | 60 |

| QuickSet Shuttering Magnet | 750 | 1.4 | 130 x 75 | 48 |

| Heavy-Duty Magnet Block | 1500 | 2.0 | 180 x 100 | 70 |

| VersaMag Formwork Tool | 950 | 1.3 | 140 x 85 | 50 |

| EasySet Magnetic Holder | 850 | 1.1 | 135 x 80 | 43 |

When selecting shuttering magnet products for your construction projects, there are several key features to consider. First and foremost, the holding power is crucial. A strong magnet can securely hold the formwork in place, ensuring that concrete is poured accurately and without leaks. Additionally, consider the durability of the magnets. Those made of high-quality materials can withstand harsh construction environments and maintain their performance over time.

Another important feature is ease of use. Look for magnets that come with user-friendly designs for quick attachment and detachment. This can significantly streamline the construction process, allowing workers to focus on their tasks rather than struggling with equipment. Adjustable features can also enhance versatility, enabling the magnets to be used in various applications.

Tips for optimizing the use of shuttering magnets include regularly inspecting them for wear and tear to prevent any unforeseen issues during operation. Moreover, it's beneficial to train your team on the best practices for handling and positioning these magnets to maximize their efficiency. By carefully assessing these features and implementing practical tips, you can greatly enhance the effectiveness of your construction projects.

When it comes to optimizing construction projects, selecting the right shuttering magnet can significantly enhance efficiency and effectiveness. Various brands have emerged as leaders in this space, each offering distinct models that cater to different project needs. These top brands are known for their innovative designs and durable materials, ensuring that their shuttering magnets deliver superior holding power and versatility on-site.

Among the popular models from these leading brands, you're likely to find features that include adjustable holding strengths, easy installation mechanisms, and weather-resistant materials. These attributes not only streamline the workflow on construction sites but also improve safety by providing reliable structures during concrete pouring.

Additionally, many of these brands invest in research and development, continuously refining their products to meet the evolving demands of the construction industry. By choosing from these trusted sources, construction professionals can ensure they have the right tools to enhance their project outcomes.

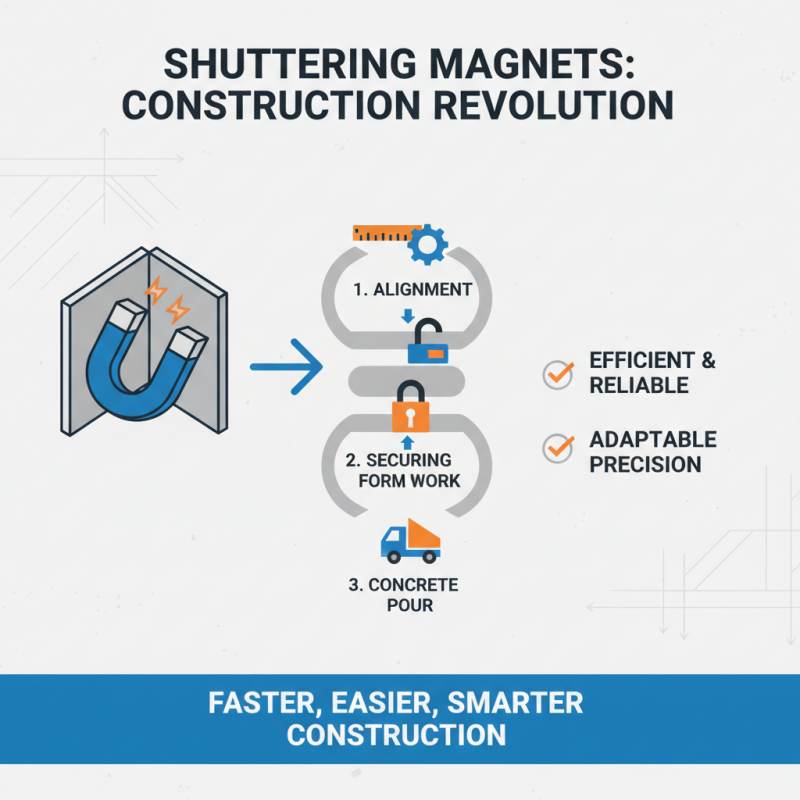

Shuttering magnets have revolutionized the way construction projects are executed, providing a reliable and efficient method for securing formwork according to project specifications. Their primary application lies in the concrete pouring phase, where the proper alignment and stability of forms are crucial. By employing shuttering magnets, construction teams can easily adjust and reposition forms without the hassle of traditional fastening methods, ensuring a seamless workflow. This adaptability is especially beneficial in complex builds where precision is paramount, allowing for the quick adjustments needed to meet varying design requirements.

In addition to improving efficiency, shuttering magnets also enhance safety on construction sites. By minimizing the need for cumbersome hardware and tools, they reduce the risk of accidents associated with manual handling of heavy materials. Moreover, their strong magnetic grip ensures that forms remain securely in place during the pouring process, preventing failures that could lead to costly rework and potential hazards. The real-world application of these products not only streamlines the construction timetable but also fosters an environment where workers can focus more on their tasks and less on securing their equipment. Ultimately, the integration of shuttering magnets in construction projects exemplifies innovation that meets both practical needs and safety regulations.

Caring for shuttering magnets is essential for maximizing their lifespan and ensuring optimal performance in construction projects. Regular maintenance not only preserves their magnetism but also enhances safety on the job site. One key tip is to routinely clean the magnets with a soft cloth to remove any debris or concrete residue that may have accumulated. This helps maintain their gripping power, ensuring that they function effectively when securing formwork.

Another important aspect of caring for shuttering magnets is to store them properly when not in use. They should be kept in a dry environment and vertically stacked to prevent unnecessary wear and tear. Additionally, applying a light coating of oil can help lubricate the surface and guard against corrosion. Implementing these simple maintenance steps can significantly reduce the risk of magnet failure during use and contribute to smoother project workflows.

Lastly, always inspect magnets for cracks or other signs of wear before deployment. Conducting these checks ensures that you can identify any potential issues before they escalate during critical stages of construction. Taking a proactive approach to the care and maintenance of shuttering magnets not only enhances their efficiency but also promotes safer working conditions on-site.