In the world of precast concrete, the demand for heavy-duty solutions has risen significantly. Leading this charge is the "2100kg Precast Concrete Magnet Factory." Experts in the industry, like Dr. Rachel Smith, emphasize the critical nature of reliability in this sector. She once stated, "A robust magnet is essential for safety and efficiency in heavy load handling."

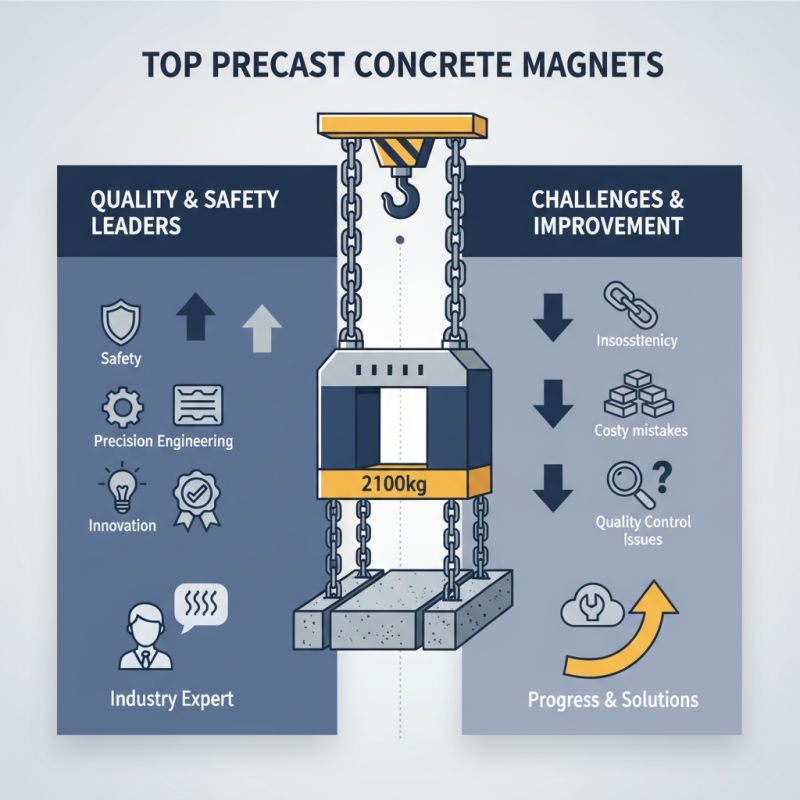

Factories specializing in precast concrete magnets know that precision is key. The strength of a 2100kg magnet can determine the success of various projects. Engineers rely heavily on these tools for safeguarding operations. However, not all factories maintain the same standard. Some struggle with quality control, and this inconsistency can lead to costly mistakes.

As heavy loads continue to challenge the construction industry, the spotlight shines on factory practices. Exploring the top precast concrete magnet factories helps identify leaders in quality and innovation. Yet, the journey isn't flawless. Assessing the shortcomings of certain operations presents opportunities for improvement. Recognizing these gaps is vital for advancing towards safer, more efficient solutions.

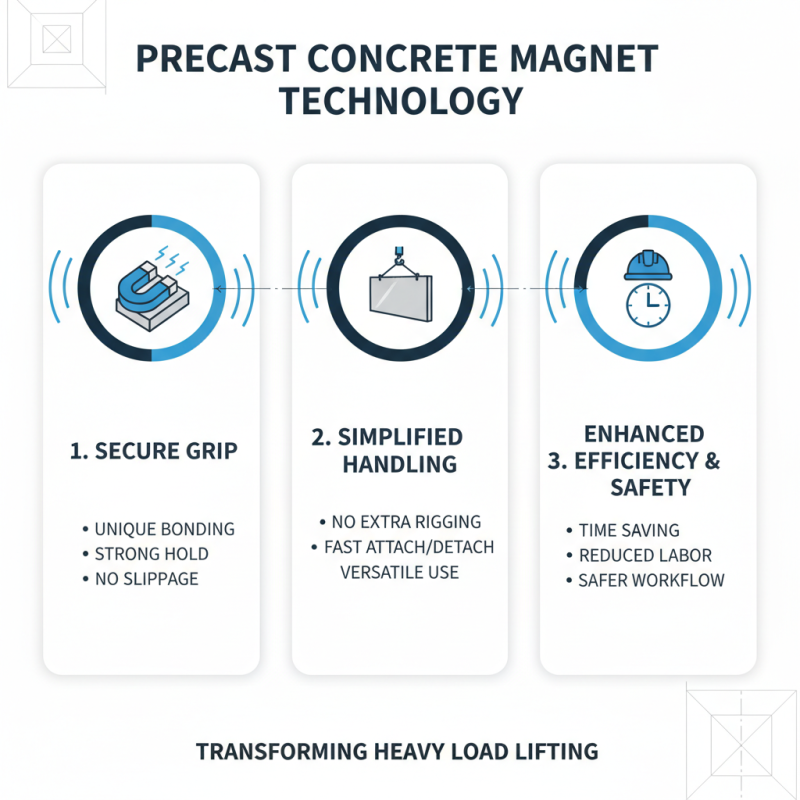

Precast concrete magnet technology is transforming the handling of heavy loads. These advanced magnets use a unique bonding method that ensures a strong grip on massive structures. Unlike traditional lifting methods, precast magnets can attach securely without extra rigging. This simplicity saves time and enhances safety on construction sites.

The technology involves a custom design tailored for specific applications. Engineers consider load types and environmental factors, optimizing the magnet's performance. However, not all designs perform flawlessly. Factors like surface conditions can affect magnet efficacy. Regular testing and adjustments are vital for maintaining performance.

Users often face challenges in understanding the limitations of these systems. Misjudgments in load capacities can lead to accidents. Ongoing education and training for operators are essential to maximize safety and efficiency. As this technology evolves, continuous feedback from users can drive further improvements.

When selecting precast concrete magnet factories for heavy loads, consider several critical factors. First, assess the factory's experience in manufacturing. A factory with years of industry presence likely has refined processes. Look for certifications that showcase compliance with safety and quality standards. These are vital for ensuring reliability in heavy-load applications.

Another important criterion is the production capacity of the factory. Facilities should efficiently handle large orders without sacrificing quality. A factory's ability to adapt to various specifications is equally significant. Customization options can lead to better fit for specific project needs.

Lastly, consider the factory's reputation in the industry. Reviews and testimonials can provide insights into their performance. However, reputations can be misleading at times, leading to poor choices. Always perform thorough research to ensure that the selected factory aligns with your project's demands and standards.

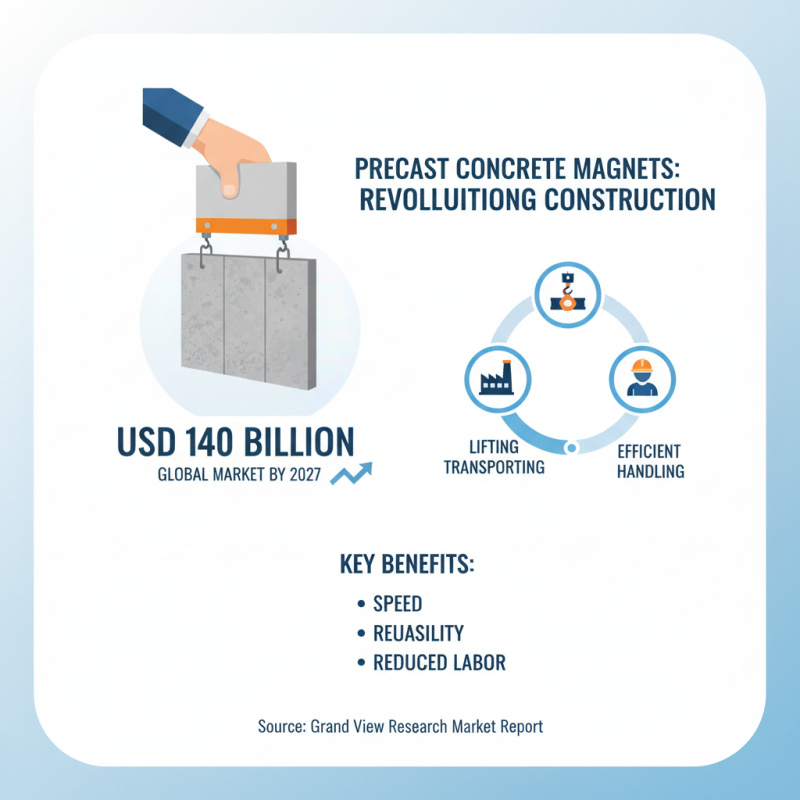

Precast concrete magnets play an essential role in the construction and manufacturing industries. They provide an efficient solution for lifting and transporting heavy loads, revolutionizing how components are handled. According to a recent market report by Grand View Research, the global precast concrete market is expected to reach USD 140 billion by 2027. This substantial growth highlights the increasing demand for precast concrete products, including magnets.

Many countries have established top-notch precast concrete factories. Some facilities boast advanced technology and automation, enhancing productivity. However, challenges remain. For instance, the reliance on skilled labor can be a bottleneck, leading to inconsistent quality across different factories. Additionally, sustainable practices are gaining traction, yet many factories still struggle to implement eco-friendly processes.

Companies must also navigate the complexities of logistics and transportation. While some areas experience a high demand for precast products, transportation costs can impact the overall project budget. Thus, finding the right balance in sourcing and manufacturing remains crucial for these factories. Investments in innovation and efficiency are necessary to stay competitive in a growing market while addressing these challenges.

When analyzing precast concrete magnet factories, key features play a crucial role. Many factories innovate by utilizing advanced materials. This enhances durability, vital for heavy loads. Their production processes often include automated systems. Automation increases efficiency but can lead to quality control challenges. These factors can significantly impact overall performance.

Tips: Always check the certification of materials used. This can prevent issues later on. Look for factories that prioritize sustainability in their production.

In addition, many factories offer custom solutions. However, customization can sometimes lead to inflated costs. Balancing quality and budget is essential. It’s worth investigating the latest technologies used in manufacturing. Innovations like high-strength concrete and magnetic adhesion methods are game-changers. Not all factories adopt these advancements promptly.

Tips: Regularly review industry trends. Staying updated can help you make informed decisions. Seek feedback from past clients to assess reliability.

The precast concrete magnet industry is evolving rapidly. This shift is driven by the demand for more durable and efficient materials. Manufacturers are starting to explore new techniques in magnet production. Innovations like advanced composite materials are on the rise. These changes may enhance the load-bearing capacity of magnets. They also could lead to reduced production costs.

Sustainability is becoming crucial. Factories are now looking at eco-friendly methods. Using recycled materials can be part of the solution. However, incorporating these practices may require a shift in current processes. This transition isn't easy for all manufacturers. They must reflect on their existing operations and make necessary adjustments.

Additionally, automation is transforming the manufacturing landscape. Smart technologies are helping factories produce magnets with greater precision. However, this raises questions about workforce displacement. Some employees might feel uncertain about their roles. Balancing technology with human expertise can be challenging. This industry must navigate these complexities as it moves forward.