Concrete construction has evolved significantly, thanks to innovative tools like Magnetic Formwork Products. These systems simplify the construction process by enhancing precision and efficiency. Magnetic formwork allows for swift adjustments, reducing the time spent on setup.

The use of Magnetic Formwork Products not only speeds up projects but also improves structural integrity. Builders benefit from easy handling and reduced labor costs. However, these advancements might come with a steep initial investment. Companies must weigh the promise of efficiency against financial limitations.

In the fast-paced world of construction, the right tools matter. Magnetic formwork has proven to be a game-changer. Yet, it requires skilled labor for optimal results. Ongoing training might be necessary to fully leverage this technology. Ultimately, assessing individual project needs is crucial before adopting such innovative solutions.

Magnetic formwork products are gaining traction in the concrete construction market. These innovative products allow for quick setup and dismantling. The magnetic mechanism enables strong adhesion to various surfaces, enhancing stability. Construction teams appreciate the time savings. However, not all applications benefit equally from this technology. It's essential to evaluate if magnetic formwork suits the specific project needs.

Market analysis reveals a growing demand for efficient building solutions. Contractors are always looking to reduce labor costs and improve productivity. Magnetic formwork provides a tangible solution. Yet, there are challenges. The initial investment can be significant. Some teams may hesitate, weighing the cost against benefits. Additionally, training is necessary for effective use. Without proper knowledge, issues can arise, affecting project timelines.

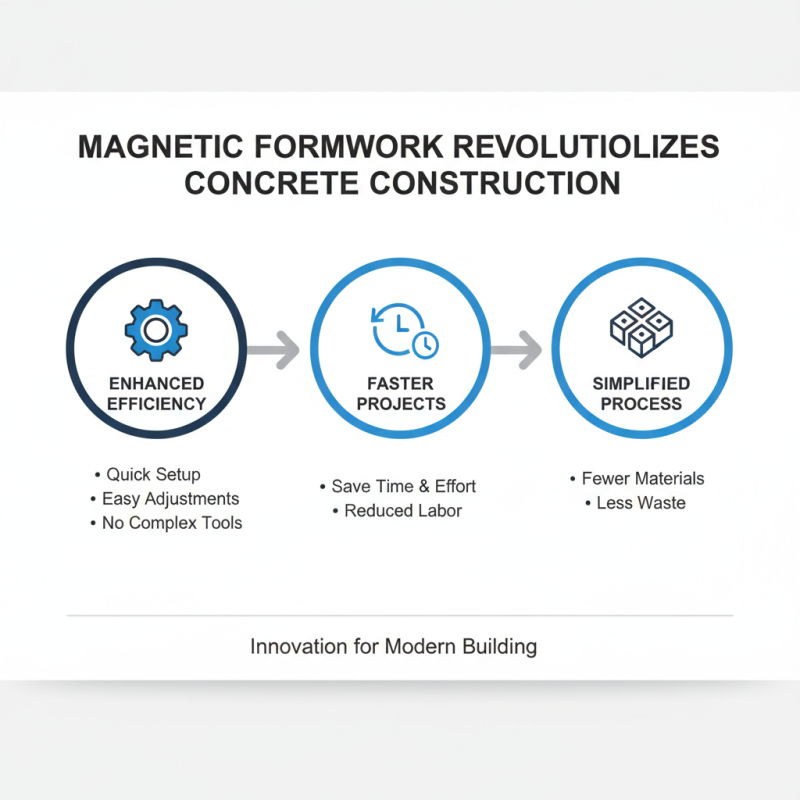

Magnetic formwork is revolutionizing concrete construction. Its unique design significantly enhances efficiency on job sites. These systems allow for quick setup and adjustments without complex tools. Workers can save time and effort, leading to faster project completion. This system reduces the need for numerous traditional materials, simplifying the construction process.

Here are some tips for using magnetic formwork effectively. First, ensure that the surface is clean and dry for optimal adhesion. Proper alignment is crucial; a slight misalignment can lead to defects in the structure. Consider testing the setup with a small concrete pour to confirm effective bonding.

Another benefit of magnetic formwork is the excellent finish it provides. The smooth surfaces help in achieving uniform concrete shapes. However, be cautious. If the formwork isn't well-maintained, it can fail to hold the concrete properly, leading to costly rework. Regular inspections and maintenance are necessary for sustained efficiency.

Magnetic formwork systems are gaining attention in the concrete construction industry. Their adaptability and efficiency are notable. A report from the Construction Industry Institute indicates that these systems can reduce labor costs by up to 30%. This improved efficiency often leads to faster project completion.

When comparing different magnetic formwork products, several factors are crucial. Load capacity, ease of assembly, and durability are key indicators of performance. Some systems offer a clamping force of over 1,200 N/m. This strength is essential for ensuring stability during pouring. However, the choice of material affects long-term use; not all options withstand harsh weather conditions effectively.

Users have reported that magnetic formwork simplifies site logistics. Less setup time means resources can be allocated elsewhere. Yet, challenges remain. Misalignment can occur if not installed correctly. This issue requires careful attention to detail, as it can compromise the entire structure. Continuous feedback from construction teams highlights the importance of training on these systems. Such insights can drive improvements in both efficiency and safety.

In 2023, innovative magnetic formwork products are transforming concrete construction. These systems simplify assembly and enhance efficiency. According to industry reports, magnetic formwork reduces setup time by up to 30%. This efficiency translates into significant cost savings on projects.

Modern magnetic formwork incorporates multiple features. Quick-release magnets allow for fast changes in design. Lightweight components facilitate easier handling. Some systems even offer adjustable heights, enhancing versatility. Industry experts suggest that these features increase site productivity remarkably.

Tips: Always evaluate the durability of materials. The longevity of formwork is crucial for sustaining quality. Additionally, ensure that your crew is trained on new systems. Misuse can lead to project delays. Regularly review the effectiveness of the magnetic systems being used. Identify any recurring issues that could impact your work flow. Each project's needs can differ significantly, impacting the overall efficiency.

| Product Type | Magnetic Strength (Lbs) | Dimensions (Inches) | Weight (Lbs) | Special Features |

|---|---|---|---|---|

| Vertical Panel | 150 | 48 x 24 | 30 | Quick Assembly |

| Horizontal Panel | 200 | 48 x 96 | 60 | Durable Coating |

| Corner Form | 100 | 24 x 24 | 25 | Easy Handling |

| Foundation Form | 250 | 96 x 48 | 80 | Reinforced Design |

| Column Form | 180 | 12 x 12 | 20 | Compact Storage |

Magnetic formwork solutions have gained attention for their efficiency in concrete construction. Several case studies reveal substantial cost savings when utilizing these innovative products. One notable example involved a mid-sized construction project. The project team decided to implement magnetic formwork for their foundations.

The results were promising. Labor costs reduced by 30%. The installation process became much quicker. Workers reported that the forms were easy to align and reusable. Time spent on adjustments dwindled. However, some challenges arose. Not all workers were familiar with this technology. Training sessions were necessary. The initial investment in magnetic systems was higher than traditional options.

In another instance, a team used magnetic formwork for a high-rise building. They highlighted the precise finish it provided. This reduced the need for additional surface treatment. Yet, they faced issues with weather. Rain delayed work, emphasizing the need for proper planning. Although the outcomes were generally positive, these experiences showed that adaptability is key in such innovative approaches.