In the ever-evolving construction industry, the demand for efficient and reliable precast concrete systems has markedly increased, driven by the growing preference for precast solutions that offer faster project completion times and reduced labor costs. The 2100kg Precast Concrete Shuttering Magnet has emerged as a pivotal component in this context, enabling secure and precise formwork positioning during the casting process. According to a recent report by Transparency Market Research, the global precast concrete market is expected to reach USD 180 billion by 2027, growing at a CAGR of 6.7%. This surge underscores the importance of selecting a top-tier manufacturer for precast concrete components, particularly the shuttering magnets, which play a crucial role in maintaining the integrity and quality of concrete structures. However, challenges such as varying quality standards and the availability of advanced technology persist, necessitating a thorough evaluation of potential suppliers to ensure optimal performance and durability in complex construction projects.

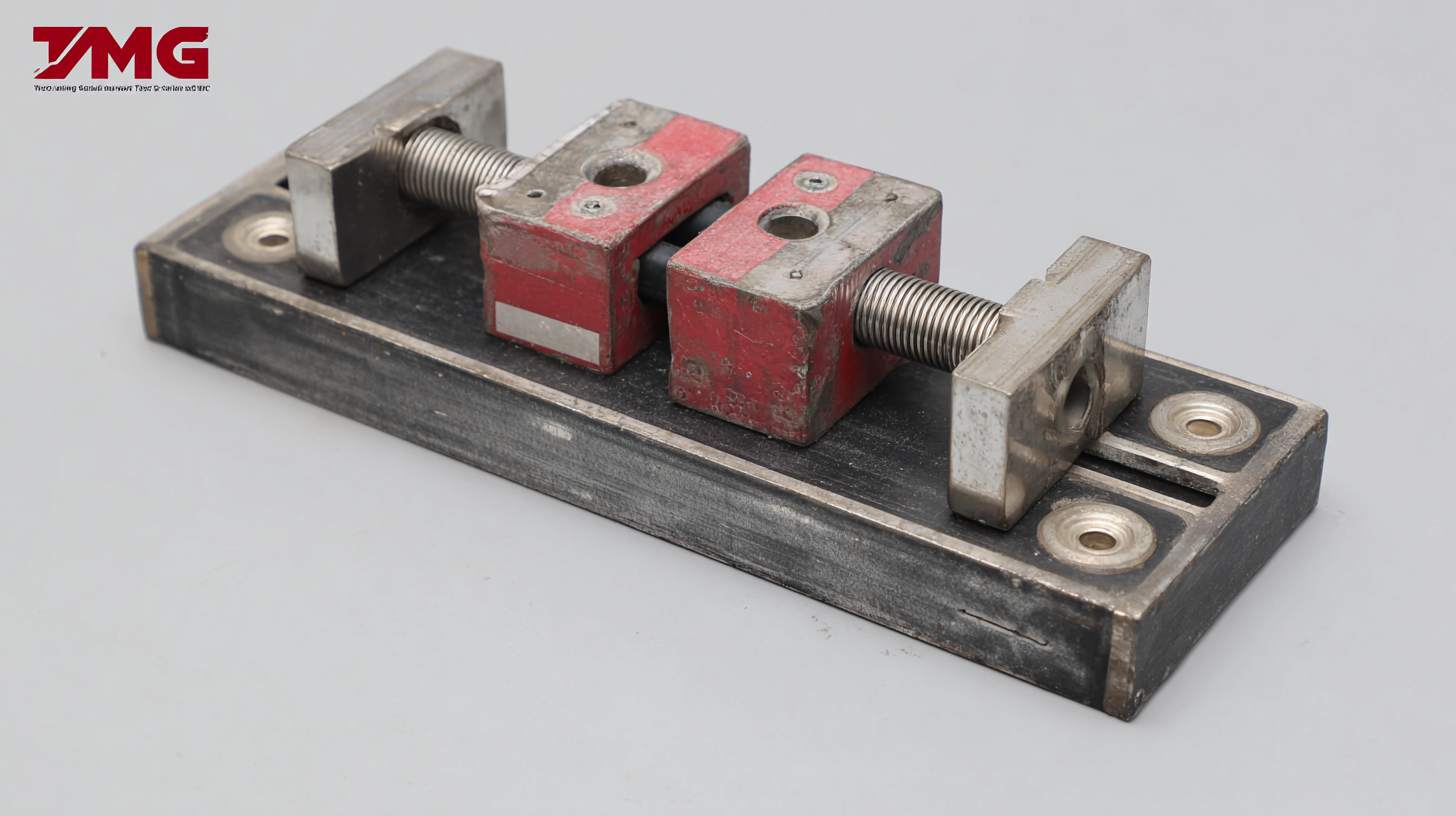

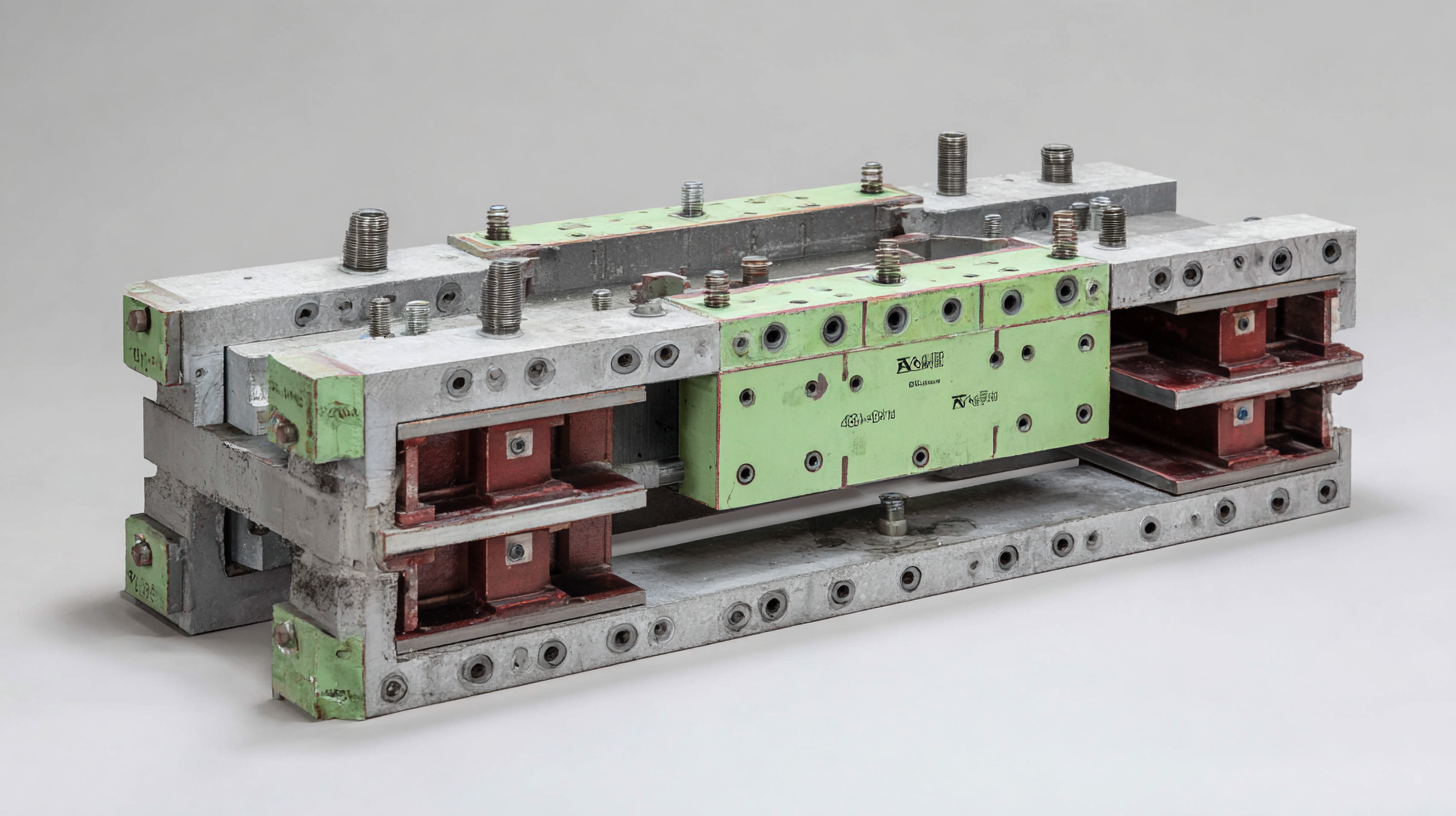

When exploring the market for precast concrete shuttering magnets, it's essential to understand the various types available and their respective benefits. Precast concrete shuttering magnets are integral to forming structures, offering efficient and sturdy support during the casting process. They come in different specifications, with the 2100kg capacity magnets being particularly sought after for large-scale projects. These magnets are designed to provide a secure hold, ensuring that formwork remains stable under various conditions, which is critical for maintaining the integrity of concrete structures.

The growth of the precast concrete market reflects a rising demand for these innovations. According to projections, the India precast concrete market is expected to reach USD 11.33 billion by 2030, with a CAGR of 9.2% from 2024 to 2030. This surge highlights the increasing reliance on advanced solutions like precast shuttering magnets in construction, driven by the need for faster construction timelines and enhanced project efficiency. As you assess potential manufacturers for these products, it's important to consider not only their technical capabilities but also their ability to meet global sourcing demands amidst a growing competitive landscape.

When selecting a 2100kg precast concrete shuttering magnet, understanding its key features is crucial for enhancing construction efficiency. These magnets are designed to ensure precise alignment and secure placement of formwork, significantly minimizing the risk of misalignment that can lead to costly rework. The robust holding power offered by these magnets allows them to withstand the heavy pressures typically associated with concrete pours, ensuring that the formwork remains securely in position throughout the curing process.

Additionally, the ergonomic design of 2100kg shuttering magnets simplifies their handling and installation on-site. Features such as quick-release mechanisms and integrated lifting points contribute to faster setup times, enabling construction teams to work more efficiently. The use of high-quality materials in manufacturing these magnets further ensures durability and long-lasting performance, reducing the frequency of replacements and associated costs. By choosing a reputable manufacturer, construction professionals can reap the benefits of increased productivity and enhanced safety on the job site.

When selecting a shuttering magnet for precast concrete applications, it’s essential to consider various factors that impact performance and efficiency. First, evaluate the weight capacity of the magnet, particularly if you are looking for a 2100kg variant. This specification is crucial as it determines the maximum load the magnet can hold securely during the casting process. More robust magnets provide better stability and can reduce the risks of displacement, ultimately enhancing the quality of the finished product.

Additionally, consider the environmental conditions to which the magnets will be exposed. Some applications may require magnets that are resistant to moisture, high temperatures, or corrosive substances. Understanding the specific demands of your precast concrete environment will help you choose magnets that offer durability and reliability over time. Finally, analyze the manufacturer’s reputation and support services. A trustworthy manufacturer not only provides high-quality products but also offers guidance for installation and maintenance, ensuring that your global sourcing needs are met efficiently.

In the realm of construction, formwork plays a critical role in shaping the future of infrastructure development. Precast concrete shuttering magnets are essential tools in this process, providing the necessary support systems for casting concrete elements efficiently. When sourcing these magnets globally, it is imperative to consider various best practices to ensure quality, cost-effectiveness, and reliability.

One of the first steps is to conduct comprehensive research on potential manufacturers. According to industry reports, the global formwork market is projected to reach approximately USD 12 billion by 2025, driven by increased investments in infrastructure projects. Understanding the market landscape can help identify key players who offer advanced technology and competitive pricing in precast concrete shuttering magnets.

Tips for effective sourcing include evaluating suppliers based on their manufacturing capabilities and certifications. Verify that they adhere to international quality standards, as suggested by key reports indicating that high-quality formwork contributes significantly to reduced project timelines and costs. Additionally, establishing strong communication channels with manufacturers can lead to better collaboration, ensuring that your specific needs are met while allowing for potential customization of products.

This chart illustrates the price per unit for various precast concrete shuttering magnets from different manufacturers. It assists in comparing options for global sourcing needs.

When sourcing precast concrete shuttering magnets weighing 2100kg, evaluating manufacturer reliability becomes paramount. Industry insights reveal that nearly 70% of sourcing decisions are influenced by a manufacturer's track record in quality and consistency. Companies that prioritize robust quality control measures significantly reduce defect rates, often below 1% compared to those with less stringent protocols, enhancing overall project productivity and cost-effectiveness.

When assessing manufacturers, consider their certifications and compliance with international standards, such as ISO 9001. This certification not only indicates quality management systems but also their commitment to continuous improvement. Another crucial consideration is the manufacturer’s capabilities in providing support and after-sales service, which can greatly affect project timelines and efficiency.

**Tip:** Always ask for case studies or references from previous clients to gauge a manufacturer's reliability effectively.

**Tip:** Evaluate the logistics and supply chain mechanisms the manufacturer has in place to ensure timely delivery.

By integrating these evaluations into your global sourcing strategy, you can confidently choose a manufacturer that meets your project's specific needs while ensuring high-quality results.

| Manufacturer Location | Production Capacity (units/month) | Experience (years) | QC Certification | Delivery Time (weeks) | Customer Satisfaction Rate (%) |

|---|---|---|---|---|---|

| Germany | 500 | 15 | ISO 9001 | 4 | 98 |

| China | 1000 | 10 | ISO 14001 | 6 | 95 |

| USA | 800 | 8 | ASTM | 5 | 97 |

| India | 600 | 12 | ISO 45001 | 7 | 92 |

| Italy | 700 | 20 | CE Mark | 3 | 99 |