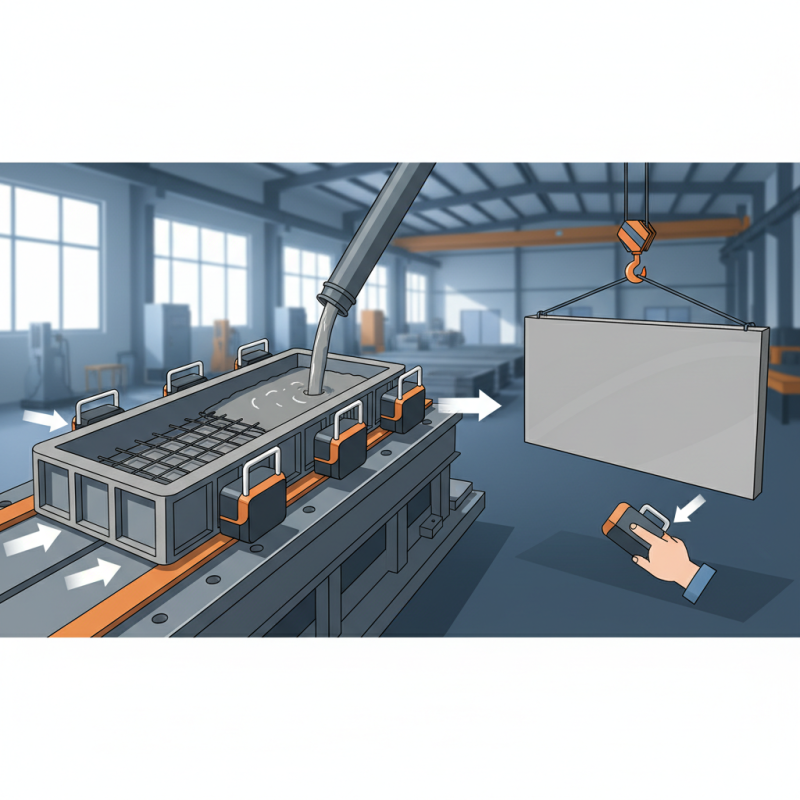

In the realm of precast production, the efficiency and quality of casting concrete heavily rely on the right tools and technologies. One such crucial element that has been gaining prominence in the industry is the use of shuttering magnets for precast production. These magnets offer a dynamic solution for securing formwork, ensuring that the components remain well-aligned during the pouring and setting of concrete. By providing robust holding power, shuttering magnets significantly minimize the risk of shifting or movement, which can compromise the integrity of the finished product.

The implementation of shuttering magnets not only enhances the overall production process but also facilitates a more streamlined workflow. Their easy placement and removal allow for flexible configurations, catering to various design requirements without the need for cumbersome clamps and fasteners. This adaptability enables producers to meet the increasing demands of modern architecture while maintaining stringent quality standards. As the precast industry continues to evolve, understanding the best practices for using shuttering magnets will be essential for manufacturers looking to optimize their operations and deliver superior concrete products. Whether you're new to precast production or looking to refine your current methods, exploring the essential tips for leveraging shuttering magnets can lead to significant improvements in efficiency and output quality.

Shuttering magnets have become an indispensable element in precast production, facilitating the construction of concrete elements with precision and efficiency. These magnets are designed to hold the shuttering forms in place during the pouring of concrete, significantly reducing the time and labor costs associated with traditional fastening methods. According to recent industry reports, the adoption of shuttering magnets can lead to a reduction in formwork assembly time by up to 80%, thereby enhancing overall productivity on construction sites.

Moreover, the utilization of shuttering magnets contributes to improved structural integrity and consistency in precast components. By ensuring that forms remain securely in place, they minimize the risk of misalignment or deformation during the curing process. Studies indicate that projects employing advanced formwork systems that incorporate shuttering magnets can achieve better quality control, yielding concrete elements with fewer defects. This not only translates to cost savings in repairs and rework but also boosts the competitiveness of precast suppliers in the market.

As the demand for precast concrete structures continues to grow, understanding the role of shuttering magnets becomes vital for manufacturers aiming to optimize their production processes. With their ability to streamline operations and enhance quality, these magnets are critical in meeting the evolving needs of the construction industry, where efficiency and precision are paramount.

In the precast concrete industry, shuttering magnets play a crucial role in the efficiency and accuracy of production. These magnets serve as an essential tool for securing formwork in place, ensuring that concrete sets in the desired shape. Among the various types available, permanent magnets and electromagnetic options are widely utilized due to their unique benefits. Permanent magnets offer the advantage of being lightweight and requiring no external power source, making them ideal for quick setups and adjustments on the job site. Electromagnetic shuttering magnets, on the other hand, provide adjustable holding power, which allows operators to customize the level of grip based on specific application needs.

According to industry reports, the global precast market is expected to grow at a compound annual growth rate (CAGR) of 5.1% from 2021 to 2028, partially driven by advancements in modular construction methods that employ effective shuttering solutions. Properly selecting and implementing shuttering magnets not only enhances the flexibility of precast production but also significantly reduces labor time and minimizes material waste. It’s estimated that using high-quality shuttering magnets can lead to a 20-30% reduction in setup time, thereby increasing overall productivity. Understanding the various types and their applications is essential for contractors looking to optimize their precast processes and achieve high-quality results.

| Type of Shuttering Magnet | Application | Load Capacity (kg) | Key Features |

|---|---|---|---|

| Permanent Shuttering Magnet | Vertical Formwork | 200 | Easy to use, reusable |

| Electromagnetic Shuttering Magnet | Heavy-Duty Applications | 500 | Strong holding force, quick release |

| Adjustable Shuttering Magnet | Custom Sizes | 300 | Versatile, adjustable height |

| Rail-Mounted Shuttering Magnet | Automated Production Lines | 400 | Increased efficiency, reduced labor |

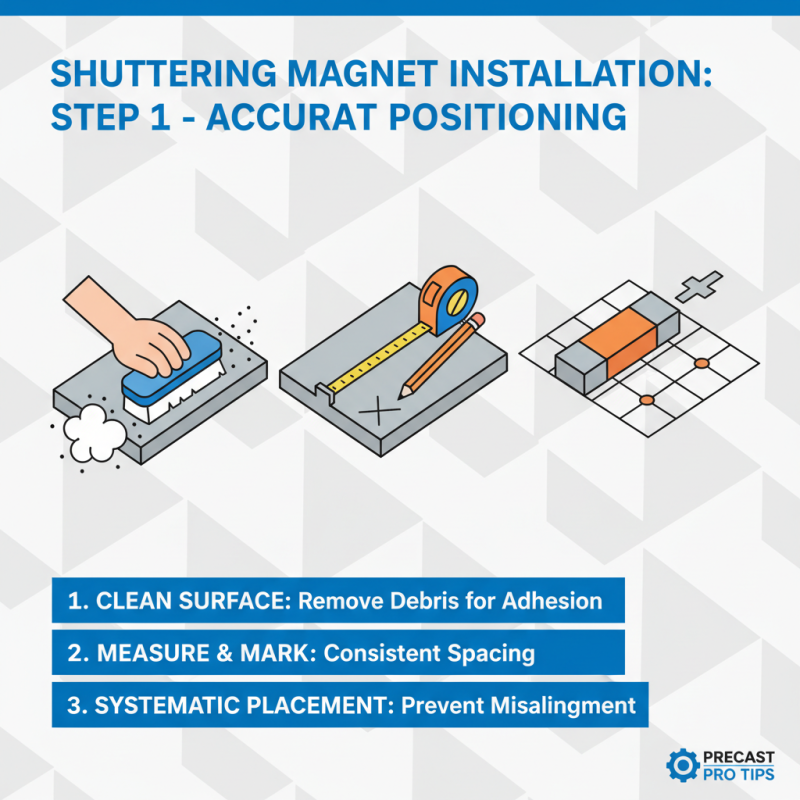

When it comes to effectively installing shuttering magnets in precast production, the first step is ensuring accurate positioning. Begin by thoroughly cleaning the surface where the magnets will be placed. This not only enhances adhesion but also prevents any debris from interfering with the magnets’ hold. Using a measuring tool, mark the intended locations to maintain consistent spacing between magnets, which is critical for even force distribution. A systematic approach to placement will minimize the risk of misalignment during the pouring process.

Another best practice involves securely fastening the shuttering magnets. Once positioned, ensure that the magnets are not only strong but also aligned perfectly with other fixtures, such as formwork. Utilizing the correct tools to tighten the magnets will help maintain their effectiveness throughout the curing process. Additionally, regular inspections during the setup phase can catch any potential issues early on, allowing for adjustments before pouring concrete. By following these guidelines, you can significantly enhance the performance and reliability of shuttering magnets in your precast production efforts.

When utilizing shuttering magnets in precast concrete production, challenges can arise that may impede efficiency and quality. One common issue is the alignment of shuttering forms. Improper alignment can lead to discrepancies in concrete dimensions, thus affecting the overall integrity of the precast element. According to a study by the Precast/Prestressed Concrete Institute (PCI), misalignment errors can increase production times by up to 20%, resulting in delays and increased costs. To counter this, it is advisable to implement rigorous alignment checks before pouring concrete, as well as employing advanced laser alignment tools that can improve accuracy.

Another prevalent challenge is the durability of shuttering magnets in high-stress environments. Weakened magnets can lead to form failures, compromising safety and project timelines. Industry reports indicate that approximately 15% of construction delays are attributed to magnet failure and improper handling. To address this, it is recommended to invest in high-quality, robust magnets specifically designed for precast applications. Regular maintenance checks and a careful assessment of working conditions can also greatly enhance the lifespan of these magnets, ensuring that they perform optimally throughout the production cycle.

To ensure the longevity of shuttering magnets used in precast production, regular maintenance and proper care are crucial. One of the most important practices is to keep the magnets free from debris and dust. Over time, the buildup of concrete residue can weaken the magnetic hold and affect the quality of the precast elements. Utilizing a soft brush or cloth to clean the surfaces of the magnets after each use can significantly enhance their performance.

In addition to routine cleaning, inspecting the magnets for any signs of wear or damage is vital. This includes checking for cracks, chips, or corrosion, which could compromise their effectiveness. Any defects should be promptly addressed, either through repairs or replacements, to avoid production delays and ensure safety. Additionally, when storing shuttering magnets, it’s essential to place them in a dry, cool environment. Moisture and extreme temperatures can lead to deterioration, so effective storage solutions contribute greatly to the longevity of the equipment used in precast production.