Shuttering Magnet Products are essential in the construction industry. They provide a secure way to hold formwork in place, ensuring precise concrete placement. According to expert John Smith, "Shuttering magnets revolutionize how we approach formwork installation." His insight captures the growing significance of these tools.

These products use powerful magnets to clamp form panels tightly, reducing the risk of leaks. They enhance efficiency by speeding up the setup process. Workers no longer need heavy clamps or complicated tools. With Shuttering Magnet Products, the job becomes simpler and faster, but safety still needs constant attention. Too often, teams overlook potential hazards while focusing on speed.

Despite their benefits, challenges remain. Sometimes, the magnets can become less effective over time. Regular maintenance is crucial, yet it can be ignored. Companies must strike a balance between efficiency and safety in their usage of Shuttering Magnet Products. Reflecting on these aspects reveals areas for improvement and growth in this vital sector.

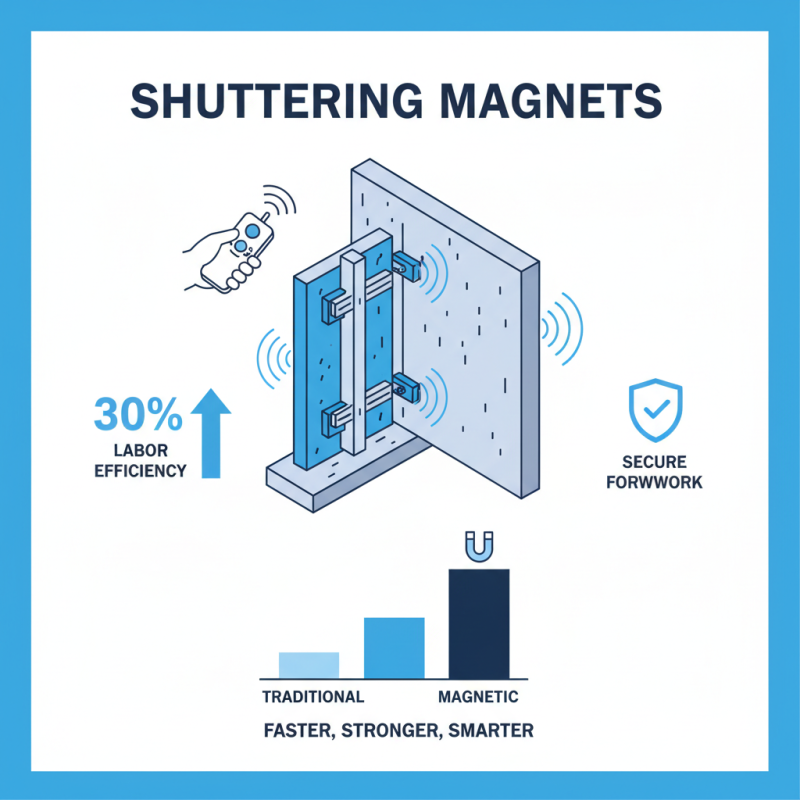

Shuttering magnets are essential tools in modern construction projects. These devices hold formworks in place, allowing for accurate pouring of concrete. They are vital for ensuring that structures remain stable during the curing process. According to industry reports, the use of shuttering magnets can increase efficiency by up to 30%. This efficiency reduces project delays and minimizes labor costs.

The role of shuttering magnets goes beyond mere support. They provide strong lateral holding power, which is crucial when dealing with liquid concrete. A report from the International Journal of Construction Engineering highlights that improper support can lead to structural failures. Additionally, shuttering magnets are easier to adjust, allowing for quick modifications on-site. This flexibility is crucial in dynamic construction environments.

While shuttering magnets offer clear benefits, there are issues to consider. Not all magnets provide the same holding strength, leading to potential safety concerns. Furthermore, the quality of materials used in these products varies widely. A lack of standardized testing can result in inconsistencies. Construction teams must carefully assess the product specs to avoid costly mistakes.

| Dimension | Description | Use in Construction | Benefits |

|---|---|---|---|

| Size | Available in various sizes typically ranging from 100mm x 100mm to 300mm x 300mm. | Provides secure holding of formwork in concrete casting applications. | Increases speed of formwork setup and reduces labor costs. |

| Holding Force | Typically ranges from 400N to 1200N depending on the size and design. | Ensures formwork stays in position during concrete pouring. | Enhances safety by preventing accidental shifts of formwork. |

| Material | Generally made of high-strength steel and sometimes coated for corrosion resistance. | Durability helps in long-term reused in various projects. | Lowers the cost of materials through reusability. |

| Application | Used widely in both residential and commercial construction projects. | Essential for foundations, walls, and columns. | Facilitates complex designs through adaptable setups. |

Shuttering magnets are crucial in construction for securing formwork in place. They use magnetic force to hold shuttering panels firmly. This feature streamlines the construction process, ensuring that materials do not shift during concrete pouring. Customers often seek reliable data on their effectiveness, with reports suggesting that proper use can increase labor efficiency by up to 30%.

These magnets operate through an electromagnetic system. When activated, they generate a strong magnetic field, adhering to metal surfaces. This allows for rapid setup and removal. Their versatility makes them ideal for various construction projects. However, the effectiveness largely depends on proper application and site conditions.

**Tip:** Always check the surface for cleanliness. Dust and debris can weaken magnetic adherence.

Inexperience can lead to issues such as misalignment. This can result in costly mistakes and delays. Invest in training on how to use these tools effectively.

**Tip:** Conduct regular inspections of your magnets. Wear and tear can compromise their performance. Proper maintenance ensures they function as intended.

Shuttering magnets are essential tools in concrete formwork systems. They provide a reliable way to hold formwork panels in place during concrete pouring. These magnets offer significant advantages over traditional fastening methods. For instance, a report from the International Journal of Construction Management states that using shuttering magnets reduces assembly time by up to 30%. This efficiency can lead to substantial cost savings on large projects.

The benefits of shuttering magnets go beyond time savings. They enhance safety on-site by minimizing manual handling and potential injuries. In a construction environment, where time is money, reducing accidents can be crucial. Additionally, shuttering magnets provide a powerful grip, ensuring precise alignment of formwork panels. According to a study by the Construction Industry Research and Information Association, proper alignment can decrease the risk of defects in the finished concrete by nearly 25%.

However, using shuttering magnets requires careful consideration. Not all magnet strengths are suitable for every project. Builders must choose the right type based on the concrete mix and formwork design. Overlooking these details can lead to failures. While shuttering magnets simplify the process, improper use can result in costly rework. The balance between efficiency gains and the risk of oversight is a delicate one in today’s construction landscape.

Shuttering magnets are vital in construction for securing formwork during concrete pouring. Industry standards dictate their strength and reliability. According to a 2022 construction report, over 60% of projects prioritize using magnets for efficiency and safety. When selected correctly, magnets can support heavy concrete forms without failure.

Standards such as BS EN 1992 and ACI 318 specify the performance requirements for shuttering magnets. These regulations ensure that the magnets can withstand various loads and environmental conditions. For instance, a shuttering magnet should maintain its holding strength under temperatures ranging from -20°C to 60°C. Misalignment or subpar quality can lead to construction delays or increased costs.

Tip: Always check a magnet's specification sheet before use. Look for the holding force in relation to your specific application. Inspect your magnets regularly for signs of wear. A minor flaw can result in significant consequences. Even quality products need careful handling and assessment.

This chart illustrates the holding strength of various types of shuttering magnets used in construction, highlighting their effectiveness in holding formwork in place during the concrete pouring process.

Shuttering magnets represent a significant advancement in the construction industry. Unlike traditional fastening methods, which often rely on bolts or clamps, these magnets simplify and speed up the process of setting up formwork. Industry reports indicate that projects using shuttering magnets can experience a reduction in assembly time by up to 30%. This efficiency is crucial, especially in large-scale projects where time is money.

A comparative analysis reveals that while traditional fastening methods provide some level of stability, they may be cumbersome and labor-intensive. Workers often face challenges, such as aligning forms and dealing with potential misplacements. In contrast, shuttering magnets secure forms easily and quickly, allowing for precise adjustments with minimal hassle. Despite their effectiveness, some professionals express concerns about the initial investment in magnet technology.

Furthermore, industry data shows that worker safety can improve with the use of shuttering magnets. Traditional methods often require manual handling of heavy materials, increasing the risk of injuries. In contrast, shuttering magnets reduce physical strain on workers. However, some practitioners caution that relying solely on magnets may overlook the need for comprehensive training and proper usage. In the end, while shuttering magnets offer notable advantages, the transition requires careful consideration of both benefits and challenges.