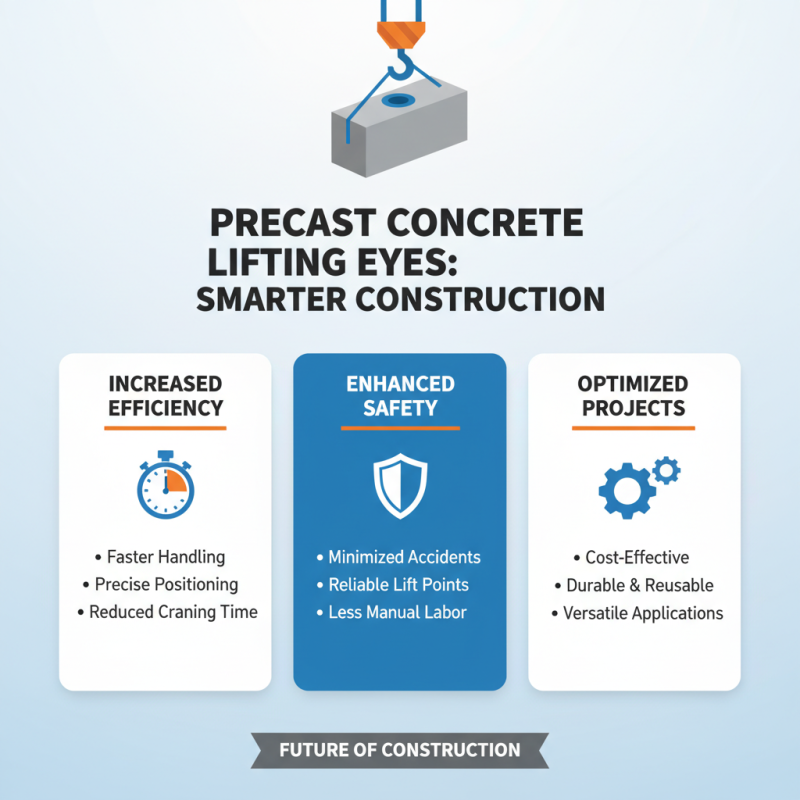

In the realm of construction, efficiency and safety are paramount. Precast Concrete Lifting Eyes play a crucial role in achieving these goals. According to a recent report by the National Ready Mixed Concrete Association, projects using precast components can enhance productivity by up to 30%. As a result, many contractors are turning to these specialized lifting solutions.

Industry expert John Smith emphasizes, "Using Precast Concrete Lifting Eyes not only ensures safety but also streamlines the lifting process." This statement underscores the value of incorporating such innovative solutions into construction practices. Precast Concrete Lifting Eyes are specifically designed to handle the weight and stress of large concrete elements, reducing the risk of accidents on-site.

However, there are challenges. Not all projects have the same requirements. The effectiveness of lifting eyes can vary depending on the project's scale and complexity. Each construction site presents unique conditions that may affect how lifting eyes perform. Thus, careful consideration is vital when implementing these tools. By reflecting on these factors, the construction industry can strive for better efficiency and safety standards.

Precast concrete lifting eyes are essential elements used in construction. They are embedded lifting devices that facilitate the handling of precast concrete products. These eyes allow workers to lift and move heavy components safely and efficiently. They come in various sizes and shapes, adapting to different project needs.

When using precast concrete lifting eyes, consider their placement carefully. Proper positioning ensures a balanced load during lifting. If they are incorrectly installed, it can lead to dangerous situations. Always check the specifications for load capacities. This minimizes risks during lifting operations.

Tip: Regularly inspect lifting eyes for signs of wear or damage. Replace any that show signs of stress. Timely maintenance can prevent failures during critical lifts.

Incorporating these lifting eyes into your project can optimize workflow. However, evaluate your project’s unique demands first. Make sure that the specifications for the lifting eyes match your concrete components. Planning and precision matter more than you might think.

| Feature | Description | Benefits |

|---|---|---|

| Design Flexibility | Precast concrete lifting eyes can be customized to various designs and applications. | Allows for tailored solutions that fit specific project requirements. |

| Strength and Durability | Manufactured under controlled conditions, offering high strength and resistance to environmental factors. | Enhanced longevity and reduced maintenance costs. |

| Ease of Installation | Designed for quick and easy lifting, saving time during the construction phase. | Faster project completion and reduced labor costs. |

| Safety Features | Integrated safety features to prevent lift failures during handling. | Increased safety for workers and reduced risk of accidents. |

| Cost-Effectiveness | Lower overall project costs due to reduced installation time and material waste. | Optimal resource utilization and improved budget management. |

Precast concrete lifting eyes are increasingly popular in construction. They offer unique benefits that enhance project efficiency and safety. These eyes are embedded in concrete components, providing reliable lifting points. This feature simplifies the handling of heavy precast elements. Workers can lift and position components accurately. This minimizes the risk of accidents on site.

Using precast concrete lifting eyes can lead to cost savings. Fewer labor hours are needed for positioning and securing elements. Additionally, they reduce the need for extra lifting equipment. However, not all projects may require lifting eyes. In some cases, traditional methods might suffice. It’s essential to evaluate specific project needs carefully.

Another aspect to consider is the potential for misalignment. If lifting eyes are not placed correctly, it can lead to issues during installation. This emphasizes the importance of proper planning and design. Construction teams should communicate effectively to ensure everything runs smoothly. Overall, when used correctly, precast concrete lifting eyes can greatly improve construction efficiency.

Precast concrete lifting eyes enhance safety and efficiency on construction sites. These specialized fixtures are embedded in precast elements. They provide reliable points for lifting and moving heavy materials. The design allows for easy integration with various precast components. Workers can focus more on their task, reducing the risk of accidents.

Moreover, using lifting eyes streamlines the lifting process. Instead of complex rigging setups, crews can use simple attachments. This speeds up the operation, saving valuable time. However, it’s essential to ensure proper installation and usage. Misalignment can lead to serious accidents. Therefore, training workers on correct procedures is crucial.

Although precast lifting eyes offer advantages, challenges still exist. Sometimes, user error can interfere with their effectiveness. Regular inspections are necessary to maintain safety. Design flaws in some lifting eyes can lead to concerns. Evaluating their performance in real-world scenarios remains important for continuous improvement.

Precast concrete lifting eyes play a crucial role in modern construction. They provide a reliable method for moving heavy precast elements safely. According to the National Precast Concrete Association, proper installation of these lifting eyes increases efficiency and reduces the chance of accidents on-site. The right placement ensures that the load is evenly distributed, which is vital for structural integrity.

When installing lifting eyes, it's essential to follow guidelines strictly. The alignment of lifting eyes should match the load's center of gravity. This is often overlooked, leading to imbalanced loads. An unbalanced lift can cause the load to swing or tip, posing risks. The American Concrete Institute recommends regular inspections to ensure all lifting eyes are secure before any operation.

Users must also consider the environmental factors affecting installation. Weather can impact the curing process of concrete. A report from the Portland Cement Association indicates that extreme temperatures can weaken concrete, thus affecting the lifting eyes' performance. It’s important to adjust procedures based on such conditions. Overlooking these factors can lead to serious issues, like equipment failure or injury.

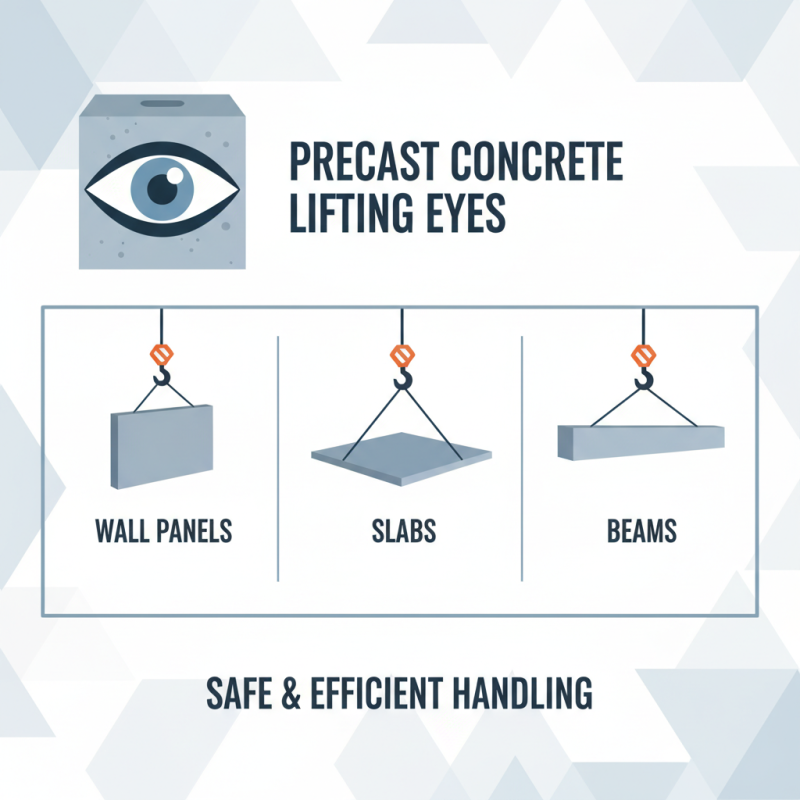

Precast concrete lifting eyes are invaluable in various construction projects. These lifting points enable safe and efficient handling of concrete components. They are commonly utilized for wall panels, slabs, and beams. The versatility of lifting eyes makes them a popular choice.

In many instances, these lifting eyes facilitate easier installation on congested job sites. Workers can quickly attach cranes or hoists, enhancing productivity. However, one should pay close attention to their placement. Incorrect positioning can lead to imbalances and potential hazards.

Some projects also demand precise weights and measurements. Miscalculations can result in structural issues, causing delays. It’s essential to assess the load capacities of lifting eyes. Inspections should be regular to ensure safety and reliability. Thoughtful consideration of these factors can lead to more successful outcomes in construction projects.